Understanding Steel Grating Thickness Importance and Applications

Steel grating is an essential component in various industrial and commercial applications, known for its durability, strength, and versatility. Among the many factors influencing its effectiveness, the thickness of the steel grating plays a crucial role. Understanding the significance of steel grating thickness is vital for selecting the right product for specific needs.

Understanding Steel Grating Thickness Importance and Applications

One of the primary considerations when choosing the thickness is the load that the grating will be subjected to. For example, a steel grating used in a manufacturing facility needs to support heavy machinery and equipment, which necessitates a thicker configuration to prevent deformation and ensure safety. In contrast, a thinner grating might suffice for decorative purposes or walkways that experience minimal foot traffic.

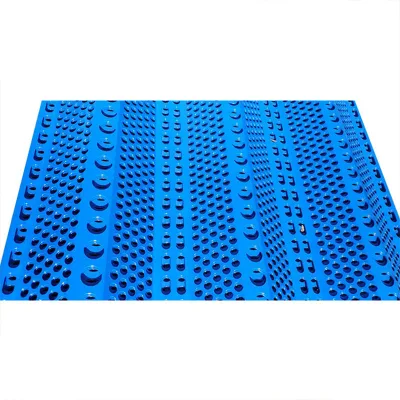

steel grating thickness

In addition to load-bearing capabilities, the thickness of steel grating also impacts installation and maintenance. Thicker gratings can be more challenging to handle and may require specialized equipment for installation. However, they often require less frequent replacement and can withstand harsh environmental conditions, such as exposure to chemicals and extreme temperatures. Therefore, the initial investment in thicker grating can yield long-term savings by reducing maintenance costs and downtime.

Moreover, the choice of thickness affects the overall aesthetics of the grating. While functionality is crucial, appearance cannot be overlooked, especially in architectural applications. Thinner grating can provide a more refined look, whereas thicker grating tends to present a more robust appearance, aligning with the style of industrial designs.

In conclusion, the thickness of steel grating is a key factor that influences its performance, durability, and aesthetic appeal. When selecting steel grating for an application, it is essential to consider the load requirements, installation complexities, and visual impact. Ultimately, the right thickness ensures safety, efficiency, and longevity, making it a critical aspect of any project that involves steel grating. By choosing appropriately, organizations can optimize performance while controlling costs effectively.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.