2 月 . 14, 2025 15:52

Back to list

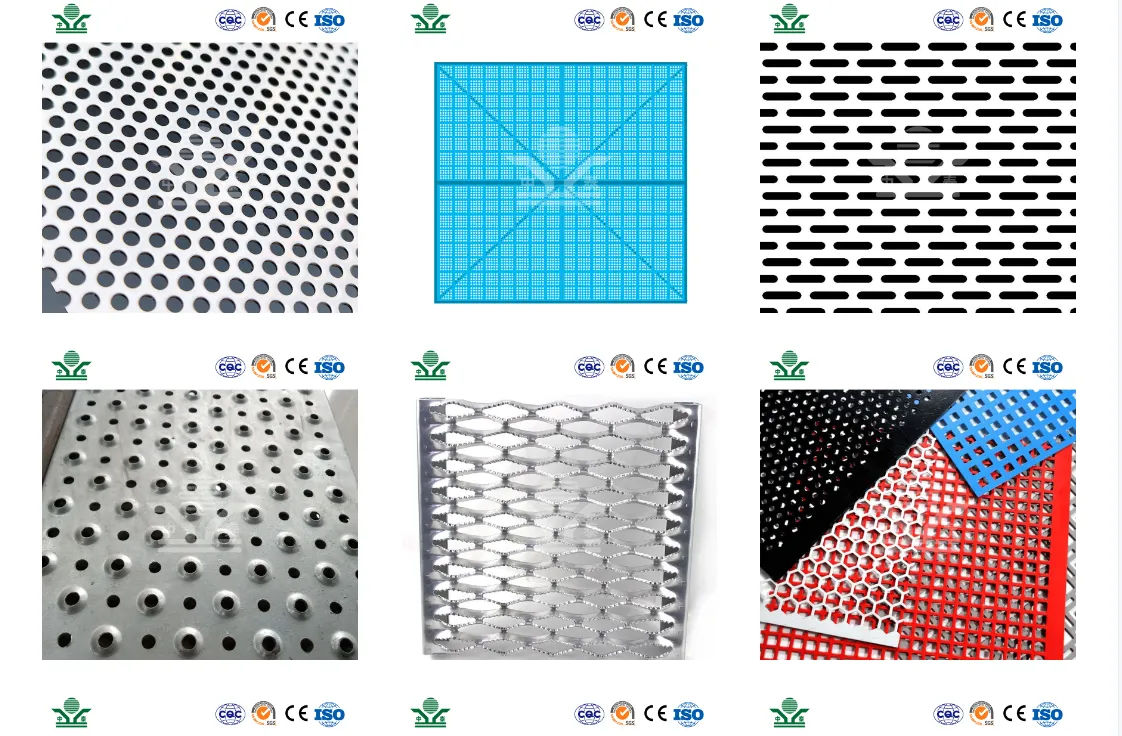

standard perforated sheet sizes

Perforated sheets, characterized by their patterned holes, are an essential component in various industries such as architecture, food processing, and automotive manufacturing. Understanding standard perforated sheet sizes is crucial for professionals and hobbyists alike to ensure their projects meet both functional and aesthetic requirements. In a competitive market, delivering precise solutions is not only about having technical knowledge but also about articulating it with clarity.

In the industrial context, these standard sizes and specifications simplify the manufacturing process, providing scalability and repeatability. Many suppliers have stock in these dimensions, ensuring quick availability, which is critical in time-sensitive projects. Furthermore, using standard sizes often translates to cost savings, as custom fabrication can be significantly more expensive. Navigating the myriad options requires expertise and experience. It demands a deep understanding of not only the mechanical properties of different materials and designs but also the environmental factors at play. For instance, a perforated sheet used in an outdoor marine environment would have vastly different specifications compared to one used in an indoor architectural setting due to factors like corrosion resistance. Authoritative guidance can significantly boost trustworthiness. It involves aligning with industry standards such as ISO 9001 for quality management and ASTM specifications for material standards, which offer assurance in product quality and performance. Experienced suppliers often provide detailed datasheets that specify the mechanical properties, corrosion resistance, and load-bearing capacities of their products, which assists in making an informed decision. Leveraging trusted suppliers also ensures articles are fabricated to precision, reducing the risk of costly errors. As projects grow in complexity, having a reliable partner for standard perforated sheet sizes becomes not only a convenience but a necessity. In essence, understanding and choosing the right perforated sheet size entails a combination of technical knowledge, industry expertise, and a tailored approach to problem-solving. Whether it's achieving optimal airflow, meeting aesthetic goals, or ensuring durable designs in harsh environments, selecting the right perforated sheet size is a testament to a well-informed, expert-driven process. It's about marrying function with form in a way that enhances both design and practicality, whether through off-the-shelf solutions or customized innovations.

In the industrial context, these standard sizes and specifications simplify the manufacturing process, providing scalability and repeatability. Many suppliers have stock in these dimensions, ensuring quick availability, which is critical in time-sensitive projects. Furthermore, using standard sizes often translates to cost savings, as custom fabrication can be significantly more expensive. Navigating the myriad options requires expertise and experience. It demands a deep understanding of not only the mechanical properties of different materials and designs but also the environmental factors at play. For instance, a perforated sheet used in an outdoor marine environment would have vastly different specifications compared to one used in an indoor architectural setting due to factors like corrosion resistance. Authoritative guidance can significantly boost trustworthiness. It involves aligning with industry standards such as ISO 9001 for quality management and ASTM specifications for material standards, which offer assurance in product quality and performance. Experienced suppliers often provide detailed datasheets that specify the mechanical properties, corrosion resistance, and load-bearing capacities of their products, which assists in making an informed decision. Leveraging trusted suppliers also ensures articles are fabricated to precision, reducing the risk of costly errors. As projects grow in complexity, having a reliable partner for standard perforated sheet sizes becomes not only a convenience but a necessity. In essence, understanding and choosing the right perforated sheet size entails a combination of technical knowledge, industry expertise, and a tailored approach to problem-solving. Whether it's achieving optimal airflow, meeting aesthetic goals, or ensuring durable designs in harsh environments, selecting the right perforated sheet size is a testament to a well-informed, expert-driven process. It's about marrying function with form in a way that enhances both design and practicality, whether through off-the-shelf solutions or customized innovations.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP