2 月 . 01, 2025 00:37

Back to list

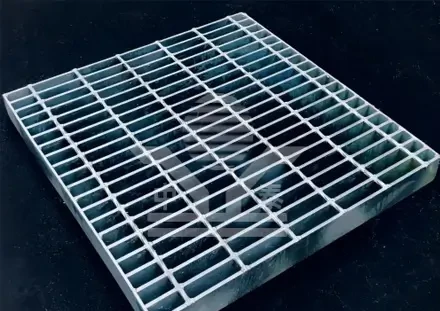

stair grating

In modern construction and industrial settings, stair grating represents an indispensable element for ensuring safety, durability, and structural integrity. With decades of application across varying sectors, stair grating has evolved to meet the increasing demands of architectural innovation and safety compliance standards.

One expert strategy in maximizing stair grating performance is through customization. By tailoring grating configurations to fit precise architectural designs or unique functional requirements, manufacturers can augment both the aesthetic appeal and practicality of the grating systems. Whether it's curving the grating panels to match a grand stairway or incorporating custom finishes to enhance slip resistance, customization offers endless possibilities. The installation process of stair grating is also critical and requires meticulous attention to detail to ensure safety and performance standards are met. Ensuring that grating panels are correctly aligned and securely attached can prevent accidents and enhance the structural integrity of stairways. Employing professional installation services guarantees adherence to safety standards and provides peace of mind in high-foot traffic areas. From a regulatory standpoint, stair grating meets and oftentimes exceeds established safety standards such as OSHA and ADA. Compliance with these regulations is mandatory to avoid costly penalties and ensure the wellbeing of users. Continuous advancements in materials and manufacturing processes are also contributing to the development of grating systems that not only comply with current standards but set new benchmarks for future projects. In summary, stair grating is an integral component in both industrial and architectural applications. Its ability to combine safety, functionality, and aesthetic appeal makes it a favored choice among industry professionals. As technology and design aesthetics continue to evolve, stair grating will undoubtedly advance, providing even more innovative solutions that cater to the ever-growing demands for safety and sustainability.

One expert strategy in maximizing stair grating performance is through customization. By tailoring grating configurations to fit precise architectural designs or unique functional requirements, manufacturers can augment both the aesthetic appeal and practicality of the grating systems. Whether it's curving the grating panels to match a grand stairway or incorporating custom finishes to enhance slip resistance, customization offers endless possibilities. The installation process of stair grating is also critical and requires meticulous attention to detail to ensure safety and performance standards are met. Ensuring that grating panels are correctly aligned and securely attached can prevent accidents and enhance the structural integrity of stairways. Employing professional installation services guarantees adherence to safety standards and provides peace of mind in high-foot traffic areas. From a regulatory standpoint, stair grating meets and oftentimes exceeds established safety standards such as OSHA and ADA. Compliance with these regulations is mandatory to avoid costly penalties and ensure the wellbeing of users. Continuous advancements in materials and manufacturing processes are also contributing to the development of grating systems that not only comply with current standards but set new benchmarks for future projects. In summary, stair grating is an integral component in both industrial and architectural applications. Its ability to combine safety, functionality, and aesthetic appeal makes it a favored choice among industry professionals. As technology and design aesthetics continue to evolve, stair grating will undoubtedly advance, providing even more innovative solutions that cater to the ever-growing demands for safety and sustainability.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP