2 月 . 11, 2025 00:16

Back to list

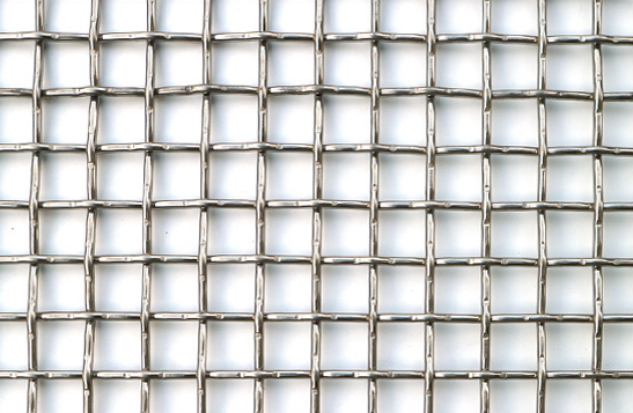

stainless steel sheet metal with holes

Stainless steel sheet metal with holes, colloquially known as perforated stainless steel, is a product that has quietly revolutionized various industries through its application versatility, durability, and aesthetic appeal. Many professionals who require reliable and long-lasting materials use this product to benefit their projects.

Authoritative recommendations often guide material selection in large-scale projects, and stainless steel sheet metal with holes is no exception. Experts from engineering bodies and design councils frequently cite the material’s performance in sustainability profiles. Because stainless steel is recyclable and requires minimal maintenance, it aligns with environmental sustainability goals—addressing both eco-conscious architects and budget-focused project managers. In professional forums and industry groups, discussions often highlight case studies where perforated stainless steel contributed to achieving LEED certification, underscoring its environmental and operational benefits. One cannot overlook the trust that clients and stakeholders place in materials with a track record of safety and reliability. Stainless steel’s resistance to fire and heat, coupled with its non-porous nature, ensures it meets stringent safety standards. In industries such as food processing and pharmaceuticals, where hygiene is paramount, stainless steel remains the material of choice due to its nonreactive surface, further fortified when perforated to enhance airflow and sanitation. In conclusion, the strategic deployment of stainless steel sheet metal with holes can dramatically enhance a project's outcome. Whether prioritizing architectural beauty, structural soundness, or environmental considerations, perforated stainless steel stands as a testament to modern engineering and design excellence. It offers not just a material solution, but a reliable partner in project success. With continued advancements in manufacturing technologies and an ever-growing appreciation for sustainable practices, its relevance and application are poised for significant growth in the coming years.

Authoritative recommendations often guide material selection in large-scale projects, and stainless steel sheet metal with holes is no exception. Experts from engineering bodies and design councils frequently cite the material’s performance in sustainability profiles. Because stainless steel is recyclable and requires minimal maintenance, it aligns with environmental sustainability goals—addressing both eco-conscious architects and budget-focused project managers. In professional forums and industry groups, discussions often highlight case studies where perforated stainless steel contributed to achieving LEED certification, underscoring its environmental and operational benefits. One cannot overlook the trust that clients and stakeholders place in materials with a track record of safety and reliability. Stainless steel’s resistance to fire and heat, coupled with its non-porous nature, ensures it meets stringent safety standards. In industries such as food processing and pharmaceuticals, where hygiene is paramount, stainless steel remains the material of choice due to its nonreactive surface, further fortified when perforated to enhance airflow and sanitation. In conclusion, the strategic deployment of stainless steel sheet metal with holes can dramatically enhance a project's outcome. Whether prioritizing architectural beauty, structural soundness, or environmental considerations, perforated stainless steel stands as a testament to modern engineering and design excellence. It offers not just a material solution, but a reliable partner in project success. With continued advancements in manufacturing technologies and an ever-growing appreciation for sustainable practices, its relevance and application are poised for significant growth in the coming years.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP