2 月 . 11, 2025 02:03

Back to list

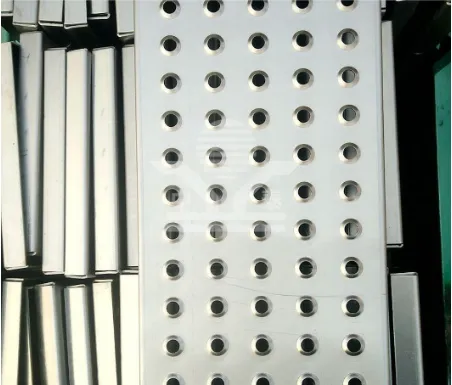

stainless steel perforated sheet metal

Stainless steel perforated sheet metal stands as a cornerstone in both architectural innovation and industrial functionality. Discovering its diverse applications and unparalleled benefits unveils why it commands a strong preference among engineers, designers, and developers.

Engaging with experts in stainless steel perforated sheet metal, one consistently comes across a shared esteem for its reliability and cost-effectiveness. Professionals emphasize that while the initial cost of stainless steel is higher compared to some alternatives, its longevity ensures superior lifecycle value, more than compensating for any upfront expenses. This long-term economic benefit extends to reduced maintenance costs and fewer replacements, reinforcing its status as an investment rather than an expense. To further highlight its authority, one can examine case studies where stainless steel perforated sheet metal played a critical role in project success. In transportation infrastructure, for instance, its strength and low maintenance became pivotal for safety and budgetary constraints in rail and airport applications. Here, its sound-dampening abilities significantly reduce noise pollution, enhancing the comfort of passengers and personnel alike. Moreover, its trustworthiness as a material choice is corroborated by rigorous testing and certification standards it meets, often exceeding expectations for both safety and quality. Its non-reactive nature ensures that it remains stable under a variety of environmental conditions, providing peace of mind to engineers and technicians involved in long-term projects. Stainless steel perforated sheet metal continues to evolve with technological advancements. Modern techniques in laser cutting and software-driven design tools allow even more precise and complex perforations, pushing the boundaries of what is possible and inspiring innovation across various sectors. This ongoing development underscores its expertise and adaptability in an ever-changing marketplace. In summary, stainless steel perforated sheet metal not only addresses pressing functional needs across industries but also does so with an authority backed by exhaustive expertise and tangible benefits. Its enduring reliability and sustainability fortify its position as an essential material, worthy of consideration for anyone looking to enhance the resilience and efficiency of their projects.

Engaging with experts in stainless steel perforated sheet metal, one consistently comes across a shared esteem for its reliability and cost-effectiveness. Professionals emphasize that while the initial cost of stainless steel is higher compared to some alternatives, its longevity ensures superior lifecycle value, more than compensating for any upfront expenses. This long-term economic benefit extends to reduced maintenance costs and fewer replacements, reinforcing its status as an investment rather than an expense. To further highlight its authority, one can examine case studies where stainless steel perforated sheet metal played a critical role in project success. In transportation infrastructure, for instance, its strength and low maintenance became pivotal for safety and budgetary constraints in rail and airport applications. Here, its sound-dampening abilities significantly reduce noise pollution, enhancing the comfort of passengers and personnel alike. Moreover, its trustworthiness as a material choice is corroborated by rigorous testing and certification standards it meets, often exceeding expectations for both safety and quality. Its non-reactive nature ensures that it remains stable under a variety of environmental conditions, providing peace of mind to engineers and technicians involved in long-term projects. Stainless steel perforated sheet metal continues to evolve with technological advancements. Modern techniques in laser cutting and software-driven design tools allow even more precise and complex perforations, pushing the boundaries of what is possible and inspiring innovation across various sectors. This ongoing development underscores its expertise and adaptability in an ever-changing marketplace. In summary, stainless steel perforated sheet metal not only addresses pressing functional needs across industries but also does so with an authority backed by exhaustive expertise and tangible benefits. Its enduring reliability and sustainability fortify its position as an essential material, worthy of consideration for anyone looking to enhance the resilience and efficiency of their projects.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP