Exploring the Versatility of Stainless Steel Perforated Metal

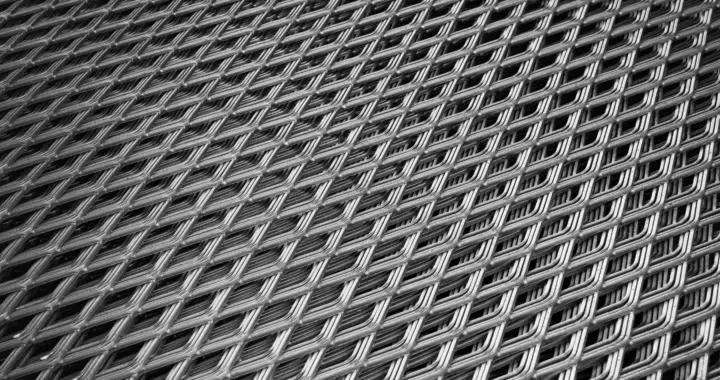

Stainless steel perforated metal is an innovative material that has gained significant popularity across various industries due to its unique combination of strength, durability, and aesthetic appeal. This versatile product is created by puncturing a stainless steel sheet with a series of holes formed in various patterns and sizes. The result is a lightweight yet incredibly resilient material that can be tailored to meet specific needs.

One of the primary advantages of stainless steel perforated metal is its exceptional resistance to corrosion. Stainless steel, known for its chromium content, naturally develops a protective layer that prevents rust and deterioration. This characteristic makes it an ideal choice for outdoor applications and environments that are prone to moisture and humidity, such as coastal areas and food processing facilities.

Beyond its functional benefits, stainless steel perforated metal offers an array of design possibilities. The perforation patterns can be customized, allowing architects and designers to create visually appealing facades and screens. From decorative panels in commercial buildings to intricate designs in residential homes, perforated metal enhances aesthetics while providing practical solutions like ventilation and light filtration.

stainless steel perforated metal

In addition to architectural applications, stainless steel perforated metal is widely used in various industrial sectors. It serves as a filtration medium in water treatment plants, as it can effectively filter out particles while allowing fluid flow. In the automotive industry, it is utilized for heat shields and soundproofing, illustrating its ability to meet rigorous performance demands. Moreover, stainless steel perforated metal finds applications in the food and beverage industry, where hygiene and safety are paramount.

The manufacturing process of stainless steel perforated metal is notably efficient. Techniques such as laser cutting and punching enable precise hole placement and size, ensuring consistent quality and performance. Additionally, this material is relatively easy to maintain; regular cleaning is typically sufficient to keep it in excellent condition, making it a low-maintenance option for both commercial and residential projects.

In summary, stainless steel perforated metal stands out as a highly versatile material that combines functionality with aesthetic flexibility. Its resistance to corrosion, customizable designs, and applications across various industries underscore its importance in modern construction and manufacturing. As innovation continues to drive advancements in material technology, stainless steel perforated metal is set to remain a top choice for architects, engineers, and designers looking for both quality and style.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.