2 月 . 11, 2025 04:31

Back to list

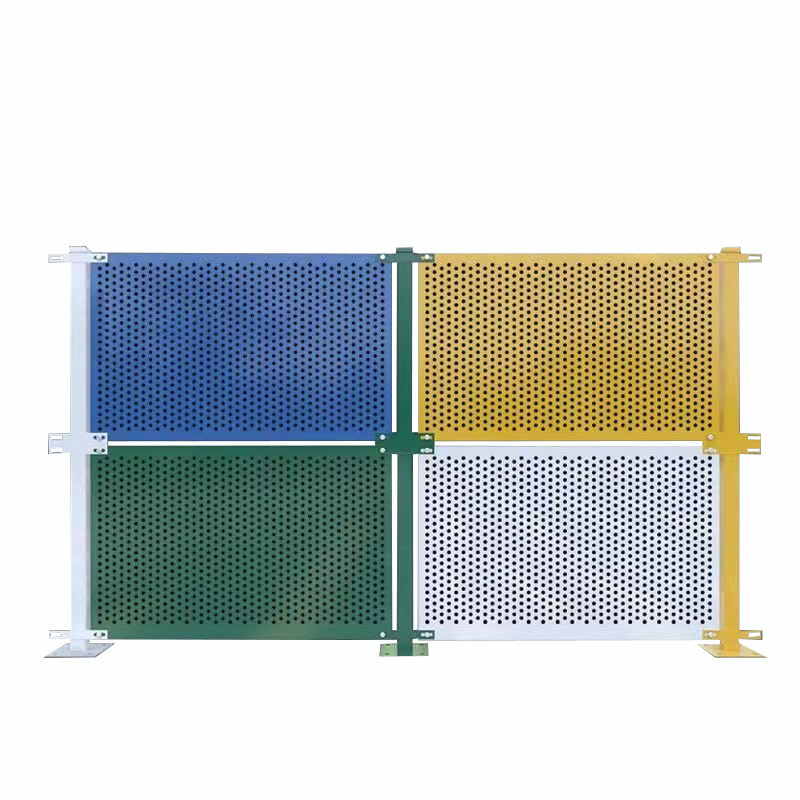

stainless steel perforated

Stainless steel perforated materials have become essential components across various industries due to their versatility, durability, and aesthetic appeal. As experts in the field with years of experience, we've witnessed firsthand how these materials have transformed countless projects, offering both functional and innovative solutions.

A unique aspect of stainless steel perforated materials lies in their aesthetic versatility. Designers leverage this by integrating these materials in various creative forms, from intricate ceiling designs to decorative wall elements. The reflective quality of stainless steel adds a dynamic dimension to spaces, interacting with light and shadow to create visually captivating environments. This adaptability extends to furniture design, where perforated elements can serve both structural and decorative purposes. Another crucial consideration is sustainability. Stainless steel is fully recyclable, aligning with global efforts toward environmental sustainability. The use of perforated stainless steel in construction and manufacturing not only reduces material waste but also contributes to the circular economy. This aspect underscores the material's role in creating sustainable solutions that are both eco-friendly and economically viable. In terms of expertise, understanding the technical properties and potential applications of stainless steel perforated materials is essential. Collaborating with manufacturers and specialists ensures that each project fully exploits the material's capabilities. Expertise in selecting the appropriate gauge, finish, and perforation pattern is crucial for meeting specific project requirements while achieving desired aesthetic outcomes. The trust we have built with our clients over the years is rooted in our commitment to quality and innovation. We prioritize understanding project needs and leveraging the full potential of stainless steel perforated materials to deliver solutions that exceed expectations. Our authoritative position in this sector is backed by successful projects and satisfied clients across various industries. Emphasizing the versatility, durability, and aesthetic potential of stainless steel perforated materials transforms how industries approach design and functionality. Our expertise and commitment to quality ensure that we remain at the forefront of this dynamic field, continually exploring new possibilities and setting standards that others follow. The confluence of sustainability, innovation, and practicality makes stainless steel perforated materials indispensable for modern projects and a testament to their enduring appeal.

A unique aspect of stainless steel perforated materials lies in their aesthetic versatility. Designers leverage this by integrating these materials in various creative forms, from intricate ceiling designs to decorative wall elements. The reflective quality of stainless steel adds a dynamic dimension to spaces, interacting with light and shadow to create visually captivating environments. This adaptability extends to furniture design, where perforated elements can serve both structural and decorative purposes. Another crucial consideration is sustainability. Stainless steel is fully recyclable, aligning with global efforts toward environmental sustainability. The use of perforated stainless steel in construction and manufacturing not only reduces material waste but also contributes to the circular economy. This aspect underscores the material's role in creating sustainable solutions that are both eco-friendly and economically viable. In terms of expertise, understanding the technical properties and potential applications of stainless steel perforated materials is essential. Collaborating with manufacturers and specialists ensures that each project fully exploits the material's capabilities. Expertise in selecting the appropriate gauge, finish, and perforation pattern is crucial for meeting specific project requirements while achieving desired aesthetic outcomes. The trust we have built with our clients over the years is rooted in our commitment to quality and innovation. We prioritize understanding project needs and leveraging the full potential of stainless steel perforated materials to deliver solutions that exceed expectations. Our authoritative position in this sector is backed by successful projects and satisfied clients across various industries. Emphasizing the versatility, durability, and aesthetic potential of stainless steel perforated materials transforms how industries approach design and functionality. Our expertise and commitment to quality ensure that we remain at the forefront of this dynamic field, continually exploring new possibilities and setting standards that others follow. The confluence of sustainability, innovation, and practicality makes stainless steel perforated materials indispensable for modern projects and a testament to their enduring appeal.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP