1 月 . 20, 2025 08:47

Back to list

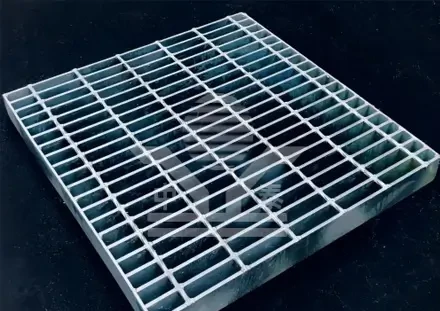

stainless expanded mesh

Stainless expanded mesh is quickly emerging as an essential material in various industrial applications, captivating both seasoned professionals and industry newcomers with its unique blend of durability and versatility. This fascinating product has made notable strides not only in traditional sectors such as construction and architecture but also in innovative domains like green energy and modern art installations.

Environmental sustainability is yet another arena where stainless expanded mesh outshines its competitors. The production process is not only free from waste but also often involves recyclable materials, adding to its eco-friendly credentials. As industries worldwide pivot towards greener practices, stainless expanded mesh stands out as a material aligned with these goals, thereby positioning users as leaders in sustainability. Furthermore, the mesh has been gaining traction in the renewable energy sector. Experts in solar and wind power installations leverage its lightweight yet durable properties to create secure mounting systems that withstand the elements without adding undue weight to structures. This has opened up new possibilities in energy-efficient design and infrastructure. Trustworthiness and authority in the field of stainless expanded mesh are established through rigorous testing and certification, affirming its compliance with international standards. This assurance is crucial for manufacturers and engineers who depend on reliable materials to achieve high standards in their work. In conclusion, stainless expanded mesh offers an unmatched combination of durability, versatility, and sustainability that meet the demanding requirements of various industries. Its expanding role across sectors is a testament to its reliability and innovative potential. Whether for enhancing architectural aesthetics, improving safety, or aligning with environmental sustainability initiatives, stainless expanded mesh is an authoritative choice backed by experience and expertise. As more industries recognize its benefits, its role as a vital material in modern applications is only set to grow.

Environmental sustainability is yet another arena where stainless expanded mesh outshines its competitors. The production process is not only free from waste but also often involves recyclable materials, adding to its eco-friendly credentials. As industries worldwide pivot towards greener practices, stainless expanded mesh stands out as a material aligned with these goals, thereby positioning users as leaders in sustainability. Furthermore, the mesh has been gaining traction in the renewable energy sector. Experts in solar and wind power installations leverage its lightweight yet durable properties to create secure mounting systems that withstand the elements without adding undue weight to structures. This has opened up new possibilities in energy-efficient design and infrastructure. Trustworthiness and authority in the field of stainless expanded mesh are established through rigorous testing and certification, affirming its compliance with international standards. This assurance is crucial for manufacturers and engineers who depend on reliable materials to achieve high standards in their work. In conclusion, stainless expanded mesh offers an unmatched combination of durability, versatility, and sustainability that meet the demanding requirements of various industries. Its expanding role across sectors is a testament to its reliability and innovative potential. Whether for enhancing architectural aesthetics, improving safety, or aligning with environmental sustainability initiatives, stainless expanded mesh is an authoritative choice backed by experience and expertise. As more industries recognize its benefits, its role as a vital material in modern applications is only set to grow.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP