Exploring Stainless Expanded Metal Mesh Versatility and Applications

Stainless expanded metal mesh has become a popular material choice across various industries, thanks to its unique properties and adaptability. This innovative mesh consists of sheets of metal that are cut and stretched to create a series of uniform openings. The result is a lightweight yet durable material characterized by its high strength-to-weight ratio. Here, we delve into the advantages, production processes, and diverse applications of stainless expanded metal mesh.

One of the primary advantages of stainless expanded metal mesh is its corrosion resistance. Crafted typically from stainless steel, this mesh can withstand harsh environmental conditions, making it particularly suitable for outdoor applications or areas exposed to moisture. Unlike traditional materials that may rust or degrade over time, stainless expanded metal maintains its integrity and appearance, even when subjected to challenging conditions.

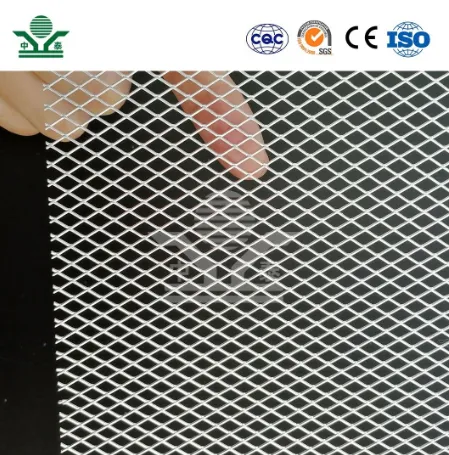

The manufacturing process of stainless expanded metal mesh is quite fascinating. It begins with a sheet of stainless steel, which undergoes a series of cuts using precise machinery. These cuts are then stretched to form diamond-shaped openings, creating a uniform mesh pattern. This process not only enhances the material's strength but also minimizes waste, making it an environmentally friendly option. The resulting product is lightweight yet robust, providing a level of durability that is unmatched by many other materials.

stainless expanded metal mesh

The applications of stainless expanded metal mesh are extensive, reflecting its versatility. In the construction industry, it is often utilized for safety screens, facades, and architectural details. Its ability to provide ventilation while maintaining structural support makes it an ideal choice for building exteriors. Furthermore, the aesthetic appeal of the mesh can enhance the visual aspect of a building, making it a favored option among architects and designers.

In the industrial sector, stainless expanded metal mesh is used for filtration systems, walkways, and machine guards. Its sturdy composition allows for effective weight distribution, making it suitable for load-bearing applications. Moreover, industries such as food processing and pharmaceuticals leverage the hygienic properties of stainless steel to ensure compliance with health standards. The mesh's easy-to-clean surface adds another layer of convenience, reducing maintenance efforts and costs.

Additionally, the automotive and aerospace industries have found valuable uses for stainless expanded metal mesh in applications such as sunroofs, grills, and ventilation panels. Its lightweight nature helps improve fuel efficiency while retaining necessary strength and safety features. As manufacturers strive to innovate and enhance designs, the demand for materials like stainless expanded metal mesh continues to rise.

In conclusion, stainless expanded metal mesh is a remarkable material that combines durability, versatility, and aesthetic appeal. The production process not only harnesses the benefits of stainless steel but also contributes to sustainability by minimizing waste. From construction to industrial applications and beyond, stainless expanded metal mesh proves itself as an invaluable asset across various sectors. As technology advances and new applications emerge, its role in modern manufacturing and design is undoubtedly set to expand further.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.