2 月 . 02, 2025 03:23

Back to list

ss grating price

Navigating the complex world of industrial materials requires a deep understanding of both quality and cost efficiency. Among these materials, SS grating, also known as stainless steel grating, plays a crucial role in a variety of sectors, including construction, transportation, and processing plants. The demand for SS grating continues to rise due to its durability, corrosion resistance, and aesthetic appeal. However, one of the most frequently asked questions remains What affects SS grating price?

Durability and maintenance are critical considerations when evaluating SS grating costs. While initial prices may seem steep compared to other materials, stainless steel’s long-term value becomes apparent. Its low maintenance requirement and resistance to damage translate into reduced repair costs over the grating’s lifespan. Additionally, its recyclability positions it as an environmentally friendly choice, which can be a decisive factor in projects where sustainability is a priority. The choice of supplier also influences the final price of SS grating. Reputable suppliers with a history of reliability and quality assurance may price their products higher than less-established competitors. However, investing in a credible supplier can assure product quality, compliance with industry standards, and reliable after-sales support, reducing the risk of incurring additional costs due to defective products or compliance issues. Strategically, understanding the lifecycle costs and benefits of SS grating allows businesses to make informed decisions. It’s essential to evaluate the Total Cost of Ownership (TCO) rather than focusing solely on upfront expenses. This approach helps in balancing cost with performance. Partnering with industry professionals can provide insights into optimizing grating selections for longevity and performance tailored to specific application requirements. In summary, SS grating price is subject to a variety of influences ranging from material choice and manufacturing processes to market trends and supplier reputation. While the upfront cost is a vital consideration, long-term performance and reliability often justify the investment. By considering these factors and working with knowledgeable industry experts, buyers can ensure that they are making economical decisions without compromising on quality. Such an informed approach not only ensures project success but also enhances operational efficiency, ultimately proving beneficial in the competitive landscape of industrial applications.

Durability and maintenance are critical considerations when evaluating SS grating costs. While initial prices may seem steep compared to other materials, stainless steel’s long-term value becomes apparent. Its low maintenance requirement and resistance to damage translate into reduced repair costs over the grating’s lifespan. Additionally, its recyclability positions it as an environmentally friendly choice, which can be a decisive factor in projects where sustainability is a priority. The choice of supplier also influences the final price of SS grating. Reputable suppliers with a history of reliability and quality assurance may price their products higher than less-established competitors. However, investing in a credible supplier can assure product quality, compliance with industry standards, and reliable after-sales support, reducing the risk of incurring additional costs due to defective products or compliance issues. Strategically, understanding the lifecycle costs and benefits of SS grating allows businesses to make informed decisions. It’s essential to evaluate the Total Cost of Ownership (TCO) rather than focusing solely on upfront expenses. This approach helps in balancing cost with performance. Partnering with industry professionals can provide insights into optimizing grating selections for longevity and performance tailored to specific application requirements. In summary, SS grating price is subject to a variety of influences ranging from material choice and manufacturing processes to market trends and supplier reputation. While the upfront cost is a vital consideration, long-term performance and reliability often justify the investment. By considering these factors and working with knowledgeable industry experts, buyers can ensure that they are making economical decisions without compromising on quality. Such an informed approach not only ensures project success but also enhances operational efficiency, ultimately proving beneficial in the competitive landscape of industrial applications.

Latest news

-

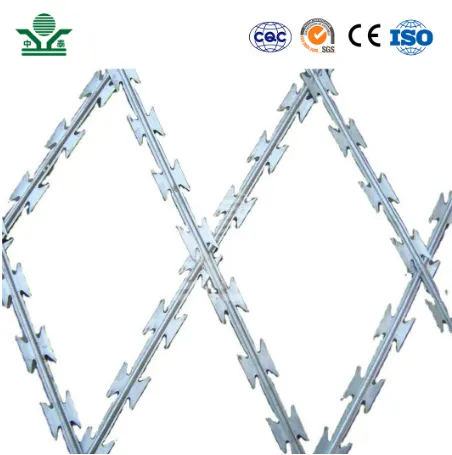

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

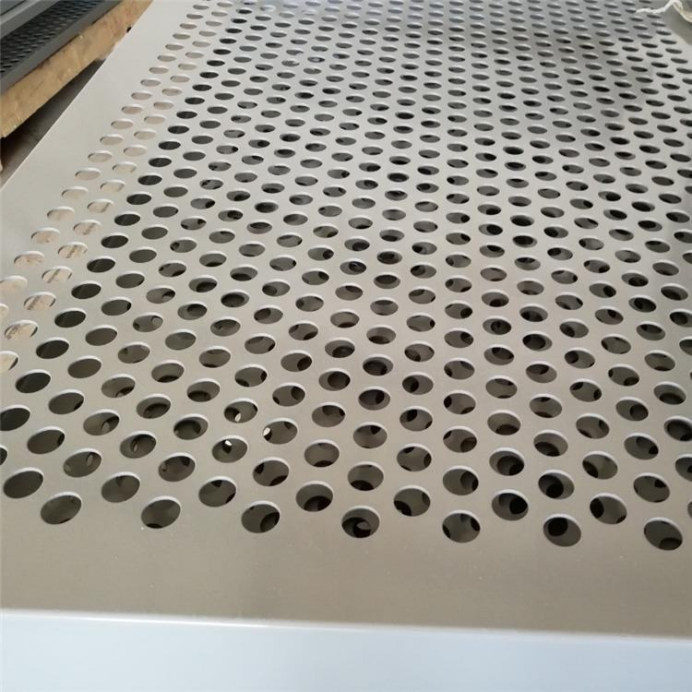

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP