2 月 . 08, 2025 04:56

Back to list

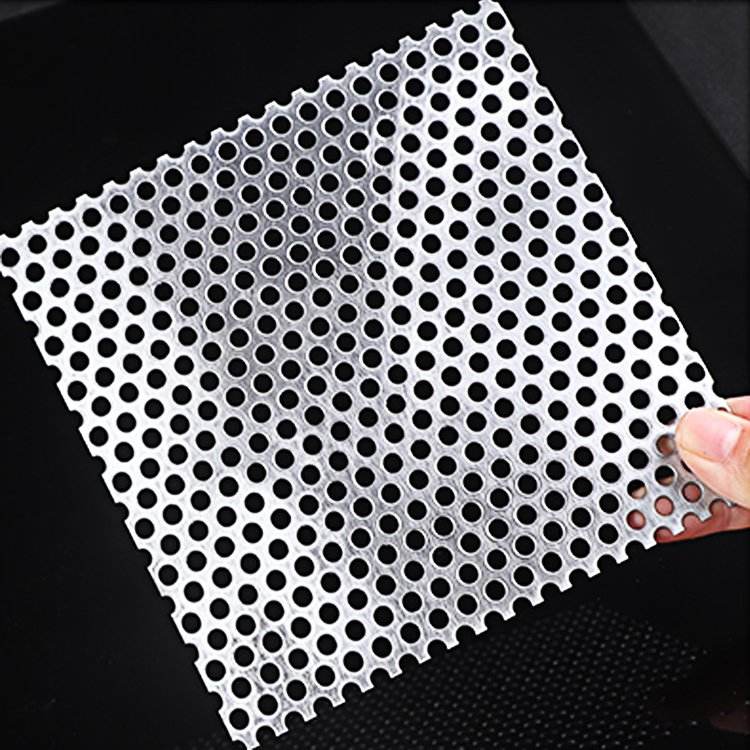

square perforated sheet

Square perforated sheets have emerged as a crucial component in various industries, owing to their unique combination of functionality, aesthetics, and adaptability. These sheets are characterized by their square patterns created through precise perforation methods, which allow for numerous applications across different sectors. In this article, we delve into the versatility and benefits of square perforated sheets, providing insights grounded in real-world experiences and expertise, while emphasizing their reliability and authority as essential materials in modern construction and design.

For industries seeking to balance weight and structural strength, square perforated sheets provide an advantageous solution. The perforation process reduces the overall weight of the sheets, allowing for easier handling and installation without compromising on strength. This aspect is particularly advantageous in the automotive and aerospace industries, where reducing weight translates into increased fuel efficiency and performance. Trustworthiness in products used for critical projects is non-negotiable, and square perforated sheets are lauded for their reliability. They adhere to stringent quality standards and testing protocols, ensuring that each sheet meets the specific needs and regulations of various industries. Manufacturers of these sheets invest heavily in research and development to innovate and improve the material quality, resulting in products that customers can trust. Another aspect that professionals appreciate is the eco-friendliness of square perforated sheets. Being recyclable and often composed of a significant percentage of recycled material, they contribute to the reduction of ecological footprints associated with construction and manufacturing. This aligns with the growing need for sustainable practices in the face of climate change and resource depletion. Widespread application of square perforated sheets is evident in various sectors including automotive, construction, food processing, and agriculture. In food processing, for example, the sheets are essential for sieving and filtration processes, ensuring that products meet hygiene and safety standards critical to public health. Similarly, in agriculture, these sheets are used in equipment for sorting and grading to provide uniformity and quality in agricultural produce, reinforcing their status as a versatile and indispensable tool across diverse fields. In summary, square perforated sheets represent an intersection of practicality and aesthetic value. Their expansive range of applications, coupled with their intrinsic properties of durability, flexibility, and sustainability, make them an authoritative choice in materials for professionals across multiple industries. Whether for enhancing architectural beauty, improving industrial processes, or building sustainable solutions, square perforated sheets stand out as a pivotal choice rooted in expertise and credibility.

For industries seeking to balance weight and structural strength, square perforated sheets provide an advantageous solution. The perforation process reduces the overall weight of the sheets, allowing for easier handling and installation without compromising on strength. This aspect is particularly advantageous in the automotive and aerospace industries, where reducing weight translates into increased fuel efficiency and performance. Trustworthiness in products used for critical projects is non-negotiable, and square perforated sheets are lauded for their reliability. They adhere to stringent quality standards and testing protocols, ensuring that each sheet meets the specific needs and regulations of various industries. Manufacturers of these sheets invest heavily in research and development to innovate and improve the material quality, resulting in products that customers can trust. Another aspect that professionals appreciate is the eco-friendliness of square perforated sheets. Being recyclable and often composed of a significant percentage of recycled material, they contribute to the reduction of ecological footprints associated with construction and manufacturing. This aligns with the growing need for sustainable practices in the face of climate change and resource depletion. Widespread application of square perforated sheets is evident in various sectors including automotive, construction, food processing, and agriculture. In food processing, for example, the sheets are essential for sieving and filtration processes, ensuring that products meet hygiene and safety standards critical to public health. Similarly, in agriculture, these sheets are used in equipment for sorting and grading to provide uniformity and quality in agricultural produce, reinforcing their status as a versatile and indispensable tool across diverse fields. In summary, square perforated sheets represent an intersection of practicality and aesthetic value. Their expansive range of applications, coupled with their intrinsic properties of durability, flexibility, and sustainability, make them an authoritative choice in materials for professionals across multiple industries. Whether for enhancing architectural beauty, improving industrial processes, or building sustainable solutions, square perforated sheets stand out as a pivotal choice rooted in expertise and credibility.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP