2 月 . 15, 2025 07:40

Back to list

Stainless Steel Plate Material Galvanized Expanded Metal Mesh

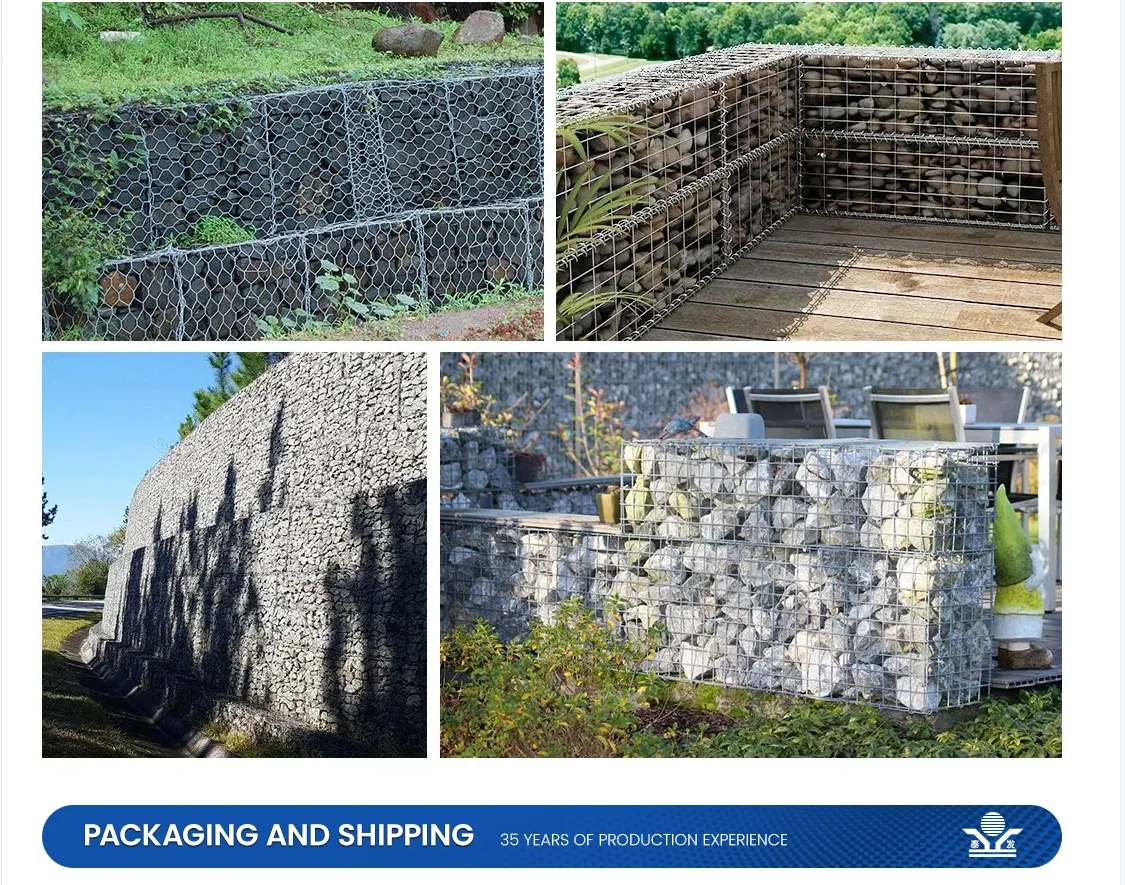

Square mesh screens have become an indispensable component across various industries due to their versatility, durability, and effectiveness. Whether you're involved in construction, agriculture, mining, or manufacturing, understanding the benefits and applications of square mesh screens can enhance your operational efficiency and ensure optimal outcomes.

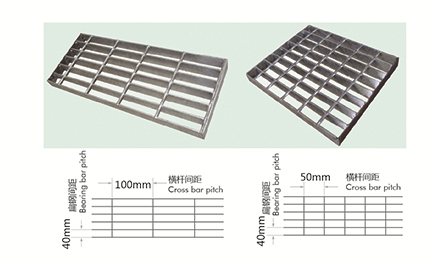

- Versatility Available in a variety of sizes and thicknesses, these screens can be customized to meet specific needs, whether you require a fine mesh for detailed filtering or a thicker mesh for structural support. - Cost-Effectiveness Their robust nature means fewer replacements, leading to lower long-term costs. The initial investment in high-quality square mesh screens pays off through minimized maintenance needs and extended use. - Ease of Use The straightforward installation process of these screens makes them user-friendly and time-efficient, which is crucial in industrial settings where time and efficiency translate to money. Selecting the Right Square Mesh Screen When selecting a square mesh screen, consider the following factors to ensure it fits your industry needs - Material Choice Depending on the application, choose a material that offers the necessary strength and corrosion resistance. Stainless steel is preferred for its balance of strength and resistance, while galvanized steel is often used where cost is a primary concern. - Mesh Size and Wire Diameter The size of the mesh and the thickness of the wire will influence the screen's function. For example, finer meshes with thinner wires are ideal for filtering small particles, while larger meshes are suited for structural applications. - Load Capacity Evaluate the load the screen will bear, especially in applications like construction, to ensure it can withstand the necessary weight without compromising structural integrity. Conclusion Investing in quality square mesh screens can significantly impact your project's success, providing reliability and efficiency across various applications. Their adaptability and robust performance make them a trusted choice in challenging industrial environments. By selecting the right materials and specifications, businesses can optimize their operations, reduce costs, and ensure a high standard of quality. With square mesh screens, industries today not only meet their productivity targets but also advance towards sustainable and innovative futures, reinforcing their importance in the modern industrial landscape.

- Versatility Available in a variety of sizes and thicknesses, these screens can be customized to meet specific needs, whether you require a fine mesh for detailed filtering or a thicker mesh for structural support. - Cost-Effectiveness Their robust nature means fewer replacements, leading to lower long-term costs. The initial investment in high-quality square mesh screens pays off through minimized maintenance needs and extended use. - Ease of Use The straightforward installation process of these screens makes them user-friendly and time-efficient, which is crucial in industrial settings where time and efficiency translate to money. Selecting the Right Square Mesh Screen When selecting a square mesh screen, consider the following factors to ensure it fits your industry needs - Material Choice Depending on the application, choose a material that offers the necessary strength and corrosion resistance. Stainless steel is preferred for its balance of strength and resistance, while galvanized steel is often used where cost is a primary concern. - Mesh Size and Wire Diameter The size of the mesh and the thickness of the wire will influence the screen's function. For example, finer meshes with thinner wires are ideal for filtering small particles, while larger meshes are suited for structural applications. - Load Capacity Evaluate the load the screen will bear, especially in applications like construction, to ensure it can withstand the necessary weight without compromising structural integrity. Conclusion Investing in quality square mesh screens can significantly impact your project's success, providing reliability and efficiency across various applications. Their adaptability and robust performance make them a trusted choice in challenging industrial environments. By selecting the right materials and specifications, businesses can optimize their operations, reduce costs, and ensure a high standard of quality. With square mesh screens, industries today not only meet their productivity targets but also advance towards sustainable and innovative futures, reinforcing their importance in the modern industrial landscape.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP