Understanding Square Hole Perforated Sheet Metal

Perforated sheet metal has become a staple in various industries due to its unique properties and versatile applications. Among the different patterns of perforation, square hole perforated sheet metal stands out for its aesthetic appeal and structural benefits. In this article, we will delve into what square hole perforated sheet metal is, its manufacturing process, applications, benefits, and considerations when choosing this material.

What is Square Hole Perforated Sheet Metal?

Square hole perforated sheet metal is a type of metal sheet that has been mechanically processed to create a pattern of evenly spaced square holes. These holes can vary in size and spacing, providing designers and engineers with flexibility in their projects. The sheet can be made from various metals, such as aluminum, stainless steel, or carbon steel, making it suitable for both functional and decorative purposes.

Manufacturing Process

The manufacturing of square hole perforated sheet metal typically involves a process called punch perforation. In this process, a metal sheet is placed in a machine, where a punch tool creates the desired patterns by removing sections of the metal. This method allows for high precision in hole placement and size, ensuring the final product meets the required specifications.

After the initial perforation, the sheets may undergo additional treatments such as deburring, which smooths the edges of the holes, enhancing the safety and visual appeal of the product. Various finishing processes, including anodizing, powder coating, or galvanizing, can also be applied to improve corrosion resistance and overall durability.

Applications

Square hole perforated sheet metal has a diverse range of applications across several sectors

1. Architecture and Construction Due to its aesthetic quality, it is frequently used in facades, ceilings, and partition walls in commercial buildings. The uniformity of square holes allows natural light to diffuse through while maintaining privacy.

2. Industrial Uses It is commonly used in filtration systems and sound dampening applications. The square holes make it effective for air flow and material processing, attracting industries like manufacturing and HVAC.

square hole perforated sheet metal

3. Interior Design Designers utilize square hole perforated metal as decorative panels in furniture, lighting fixtures, and wall art, adding a modern touch to interior spaces.

4. Security Fencing The strong structural integrity of perforated metal makes it an excellent choice for fencing solutions that require visibility while ensuring safety and security.

Benefits

Choosing square hole perforated sheet metal offers numerous benefits

- Aesthetics The uniform square holes create a clean, modern look that can enhance the design of any project. - Strength and Durability Metal sheets maintain their strength despite perforation, making them suitable for load-bearing applications. - Lightweight The perforations reduce the weight of the material without compromising its strength, which can lead to savings in transportation and installation costs. - Ventilation and Filtration The open spaces allow for air circulation, making these sheets ideal for applications requiring ventilation or filtration.

Considerations When Choosing

When selecting square hole perforated sheet metal, several factors should be taken into account

- Material Type Choose a material that best suits the environment and application. For instance, stainless steel offers greater corrosion resistance than carbon steel. - Hole Size and Spacing The size and arrangement of the holes should align with the specific requirement of your application, whether for aesthetics or functionality. - Finish Consider the environmental conditions the sheet will be exposed to and choose appropriate surface finishes to enhance longevity.

Conclusion

Square hole perforated sheet metal is a versatile and functional material that bridges the gap between practicality and aesthetics. Its unique properties make it an excellent choice for various applications, whether in construction, manufacturing, or design. By understanding its benefits and considerations, one can make informed decisions that enhance both the functionality and visual appeal of their projects.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

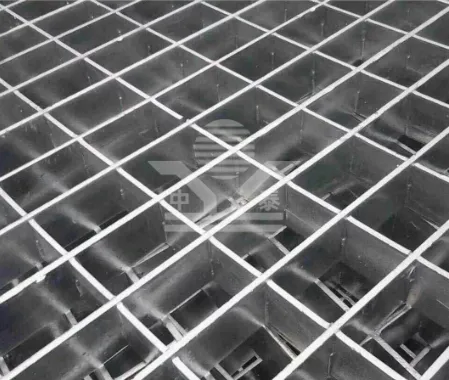

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.