2 月 . 18, 2025 06:14

Back to list

sound deadening materials

For those embarking on the journey to create a quieter, more serene environment within their homes or vehicles, understanding the intricacies of sound deadening materials is paramount. Sound pollution is a pervasive issue, often unnoticed until one experiences a haven of tranquility. Sound deadening, or noise reduction is achieved by strategically using materials designed to absorb sound waves, effectively minimizing noise interference.

Experience has shown that every environment presents unique challenges. For example, residential projects may tackle noise from neighbors or street traffic, whereas industrial environments focus on machine noise reduction. Tailoring materials and techniques to meet the specific requirements of the space ensures the best possible outcome. Authoritative voices in the field consistently emphasize the importance of trusted brands. Selecting materials from reputable manufacturers guarantees not only quality but also compliance with safety standards. Furthermore, these brands often provide detailed installation guides and customer support, invaluable resources for both novices and seasoned veterans. Trustworthiness in sound deadening materials comes down to performance and reliability. Consumers are encouraged to diligently review product specifications and customer testimonials. Objective comparisons and reviews offer insights that can guide purchasing decisions, ensuring the chosen products align with actual needs and expectations. In conclusion, the quest for effective sound deadening solutions is guided by leveraging materials that showcase proven performance, a commitment to quality from trusted manufacturers, and expertise in their application. Whether the goal is to create a personal haven of peace in a bustling urban environment or to enhance audio experiences in a vehicle, selecting the right sound deadening materials transforms a space, allowing for an environment where sound is managed with precision and ease. The synergy of the right materials and informed application elevates any project, ensuring a lasting and profound reduction in unwanted noise.

Experience has shown that every environment presents unique challenges. For example, residential projects may tackle noise from neighbors or street traffic, whereas industrial environments focus on machine noise reduction. Tailoring materials and techniques to meet the specific requirements of the space ensures the best possible outcome. Authoritative voices in the field consistently emphasize the importance of trusted brands. Selecting materials from reputable manufacturers guarantees not only quality but also compliance with safety standards. Furthermore, these brands often provide detailed installation guides and customer support, invaluable resources for both novices and seasoned veterans. Trustworthiness in sound deadening materials comes down to performance and reliability. Consumers are encouraged to diligently review product specifications and customer testimonials. Objective comparisons and reviews offer insights that can guide purchasing decisions, ensuring the chosen products align with actual needs and expectations. In conclusion, the quest for effective sound deadening solutions is guided by leveraging materials that showcase proven performance, a commitment to quality from trusted manufacturers, and expertise in their application. Whether the goal is to create a personal haven of peace in a bustling urban environment or to enhance audio experiences in a vehicle, selecting the right sound deadening materials transforms a space, allowing for an environment where sound is managed with precision and ease. The synergy of the right materials and informed application elevates any project, ensuring a lasting and profound reduction in unwanted noise.

Next:

Latest news

-

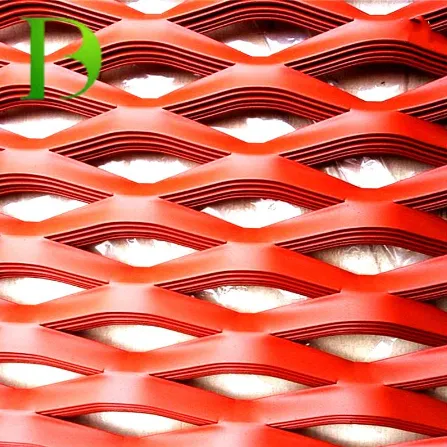

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP