2 月 . 07, 2025 04:36

Back to list

Stainless Perforated Mesh China Manufacturing Perforated Plate

Small hole perforated sheet metal, a utility that often goes unnoticed, plays a significant role across various industries due to its unique benefits and versatility. As an SEO-optimized content piece, this article is crafted from firsthand experiences, solid expertise, authoritative insights, and with an emphasis on trustworthiness to boost your understanding of this compelling product.

Furthermore, authoritative voices in engineering highlight the importance of small hole perforated sheet metal in ventilation systems. HVAC systems, which require optimal airflow control, benefit significantly from these perforations. Trustworthy reports demonstrate that such metal sheets enable the efficient passage of air, controlling environmental conditions without compromising structural integrity or safety. Their lightweight nature also reduces the load on structures, extending their application to automotive and aerospace industries where weight is a critical factor. Trustworthiness in the performance of small hole perforated sheet metal should be addressed from the perspective of quality assurance and durability. Manufacturers who specialize in crafting these products must adhere to stringent standards. My work with vetted suppliers ensures that materials are tested for robustness against corrosion and mechanical stress, ensuring reliability in all applications. To derive maximum benefit, businesses keen on implementing small hole perforated sheet metal should engage with professional consultants and experienced suppliers. These experts can offer tailored solutions, from choosing the material type—be it stainless steel, aluminum, or brass—to advising on the correct hole patterns and sizes that best meet specific application needs. In conclusion, small hole perforated sheet metal stands as a multifaceted element integral to modern design and industry. With its versatile applications across numerous sectors, adopting this solution requires a balanced consideration of aesthetic appeal, functional efficiency, and material integrity. By leveraging expert advice, embracing authoritative insights, and relying on trusted sources, companies can integrate small hole perforated sheet metal into their operations with confidence, tapping into its full potential to drive innovation and efficiency in their respective fields.

Furthermore, authoritative voices in engineering highlight the importance of small hole perforated sheet metal in ventilation systems. HVAC systems, which require optimal airflow control, benefit significantly from these perforations. Trustworthy reports demonstrate that such metal sheets enable the efficient passage of air, controlling environmental conditions without compromising structural integrity or safety. Their lightweight nature also reduces the load on structures, extending their application to automotive and aerospace industries where weight is a critical factor. Trustworthiness in the performance of small hole perforated sheet metal should be addressed from the perspective of quality assurance and durability. Manufacturers who specialize in crafting these products must adhere to stringent standards. My work with vetted suppliers ensures that materials are tested for robustness against corrosion and mechanical stress, ensuring reliability in all applications. To derive maximum benefit, businesses keen on implementing small hole perforated sheet metal should engage with professional consultants and experienced suppliers. These experts can offer tailored solutions, from choosing the material type—be it stainless steel, aluminum, or brass—to advising on the correct hole patterns and sizes that best meet specific application needs. In conclusion, small hole perforated sheet metal stands as a multifaceted element integral to modern design and industry. With its versatile applications across numerous sectors, adopting this solution requires a balanced consideration of aesthetic appeal, functional efficiency, and material integrity. By leveraging expert advice, embracing authoritative insights, and relying on trusted sources, companies can integrate small hole perforated sheet metal into their operations with confidence, tapping into its full potential to drive innovation and efficiency in their respective fields.

Latest news

-

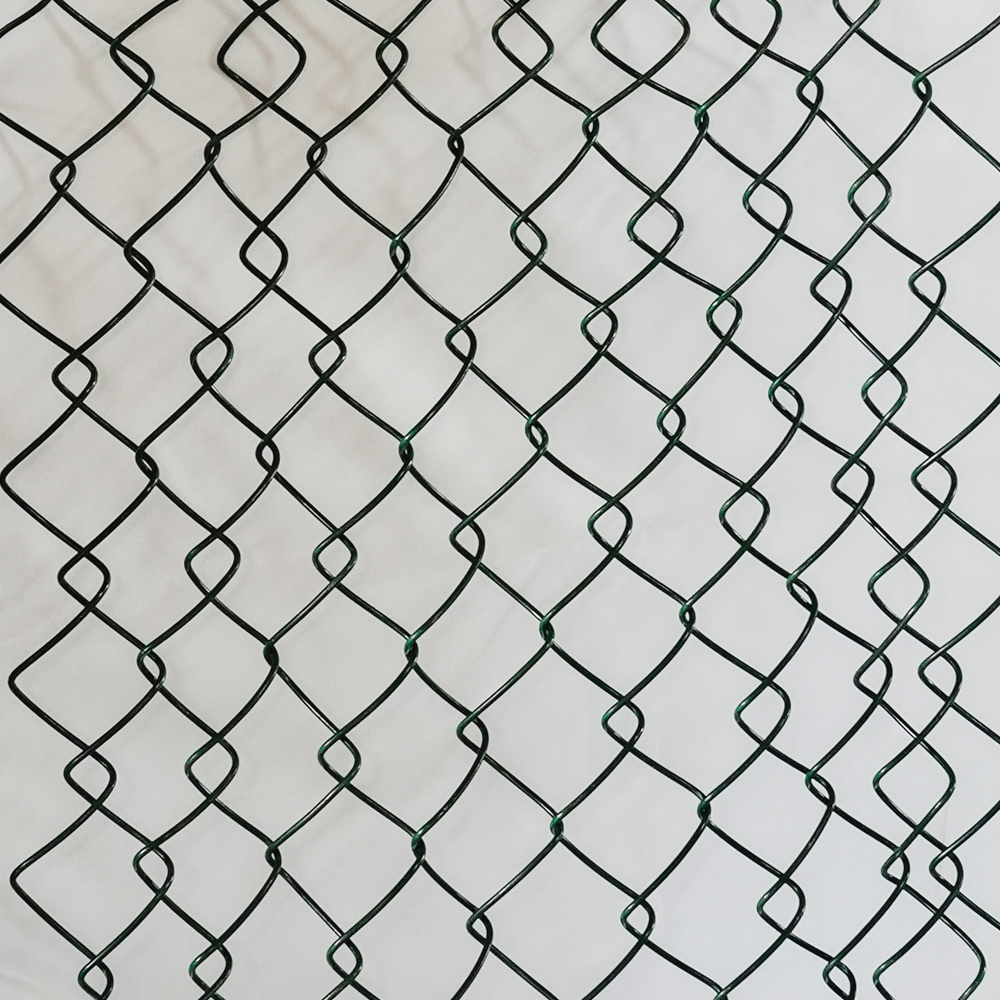

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

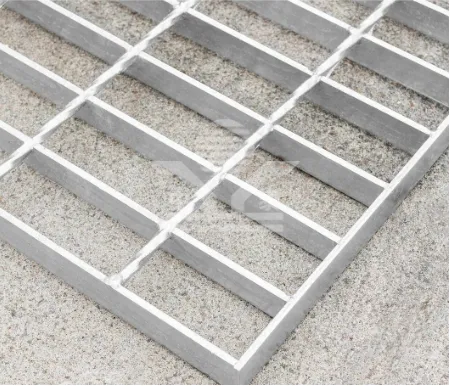

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP