The Versatility and Applications of Slotted Hole Perforated Metal

In the realm of modern engineering and architecture, perforated metal has evolved into an essential material that finds its utility across various industries. Among the different types of perforated metal, slotted hole perforated metal holds a particular significance due to its unique design, functionality, and aesthetic appeal. This article delves into the characteristics, manufacturing processes, advantages, and diverse applications of slotted hole perforated metal.

Characteristics of Slotted Hole Perforated Metal

Slotted hole perforated metal features a series of elongated holes or slots that are uniformly distributed across a metal sheet. Unlike standard round holes, these slots provide increased surface area and improved airflow and drainage, making them an ideal choice for various engineering applications. The dimensions, spacing, and orientation of the slots can be customized according to specific project requirements, thus offering versatility in design.

Typically, slotted perforated metal sheets are available in materials such as stainless steel, aluminum, and carbon steel. This variation in material selection allows designers and engineers to choose the appropriate metal based on factors such as strength, corrosion resistance, and weight. Additionally, slotted perforated metal can undergo various surface treatments, including powder coating and anodizing, to enhance its durability and aesthetic appeal further.

Manufacturing Process

The manufacturing process of slotted hole perforated metal involves several steps, primarily utilizing advanced machinery for precision and efficiency. The initial phase involves selecting the appropriate metal sheet, followed by the cutting process. Using tools such as laser cutters, punches, or water jets, manufacturers create the slotted patterns according to custom specifications.

One of the key advantages of modern manufacturing techniques is the ability to produce intricate designs with minimal waste. CNC (Computer Numerical Control) technology enables manufacturers to achieve high levels of accuracy and repeatability, which ensures that each produced sheet meets stringent quality standards.

Advantages of Slotted Hole Perforated Metal

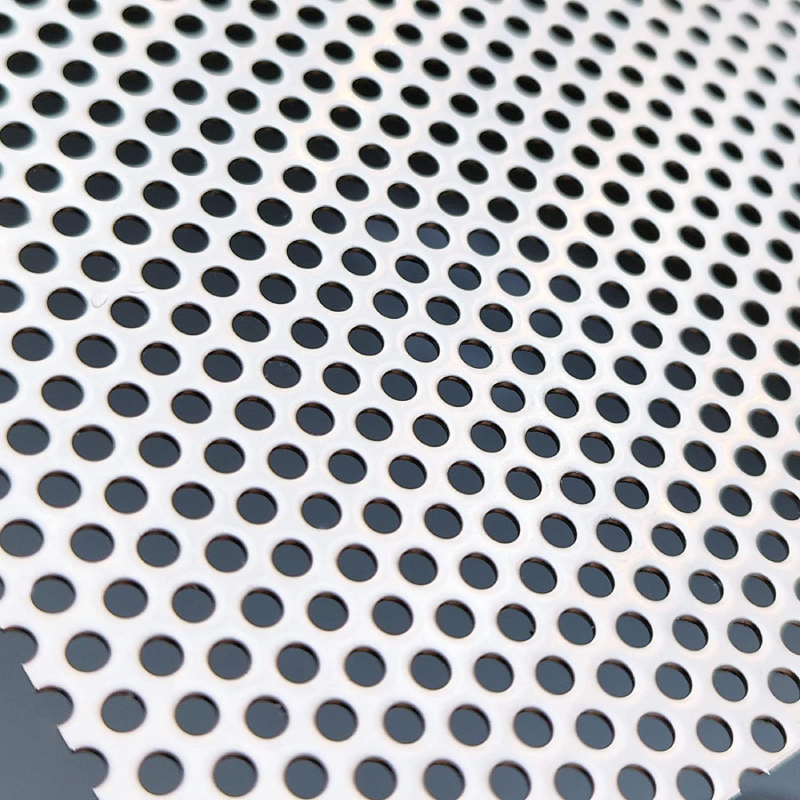

slotted hole perforated metal

Slotted hole perforated metal offers multiple advantages that render it a valuable addition to various projects. Firstly, its design enhances airflow which is crucial in applications such as HVAC systems where proper ventilation is essential. The elongated slots allow for unobstructed air movement, helping maintain comfortable environments in commercial and industrial spaces.

Secondly, slotted hole perforated metal is lightweight yet strong, making it suitable for applications where weight is a significant consideration, such as in architectural facades or shielding

. This strength-to-weight ratio not only contributes to the material’s durability but also supports sustainable construction practices by minimizing the overall material used.Moreover, the aesthetic possibilities provided by slotted hole perforated metal are immense. They can serve as decorative cladding, sunshades, or screens in architectural designs, allowing for creative expression while fulfilling functional requirements. This combination of functionality and design flexibility allows architects to seamlessly integrate perforated metal into their projects.

Diverse Applications

The applications of slotted hole perforated metal are vast and varied. In the architectural sector, it is increasingly used for facades, privacy screens, and decorative elements. The unique patterns can filter light while providing visual interest, enhancing both the building’s beauty and its energy efficiency.

In industrial applications, slotted perforated metal is often found as part of equipment enclosures, noise barriers, and filters. Its ability to allow airflow while maintaining material integrity makes it ideal for machinery and ventilation systems. Furthermore, in the manufacturing realm, it is commonly used as flooring in walkways, enabling easy drainage while ensuring safety.

Moreover, slotted hole perforated metal has significant applications in transportation, particularly in the automotive and aerospace industries. Its lightweight characteristics contribute to fuel efficiency while maintaining structural strength in components such as panels and brackets.

Conclusion

Slotted hole perforated metal represents a remarkable fusion of form and function, with its versatile applications spanning architecture, industry, and transportation. As manufacturers continue to innovate in terms of design and production techniques, the future of slotted hole perforated metal is bright, paving the way for even more creative and functional uses in various sectors. Whether enhancing the aesthetic appeal of a building or improving airflow in a mechanical system, slotted hole perforated metal ultimately stands as a testament to the power of effective design and engineering.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.