2 月 . 08, 2025 02:12

Back to list

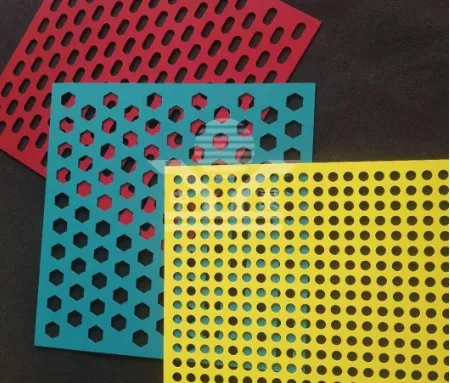

screen metal sheet

Screen metal sheets are transforming industries with their versatility and robustness, yet selecting the right one requires a blend of experience, expertise, authoritativeness, and trustworthiness. In essence, a screen metal sheet isn't just a flat piece of alloy. It’s a pivotal component that influences the performance, durability, and efficiency of various applications from architectural projects to industrial processes.

Authoritative sourcing of screen metal sheets is essential. Reputable manufacturers adhere to strict quality controls and industry standards, ensuring sheets stand up to specified loads, wear, and environmental exposure. They provide technical datasheets, which novice and veteran users alike can trust for information on mechanical properties, chemical compositions, and recommended application uses. Such authoritative data is indispensable for ensuring both safety and longevity in usage. From a trustworthiness perspective, the quality of screen metal sheets extends beyond manufacturing and material selection. It incorporates handling, installation, and maintenance practices. Improper installation can lead to structural failures and loss of efficiency, whereas regular maintenance—such as cleaning and corrosion protection—ensures the prolonged service life of these metal sheets. Feedback from industries using screen metal sheets showcases their reliability and efficiency across various applications. Sectors ranging from agriculture, where screens are used to sort grains and protect against pests, to mining, where they serve as crucial sieving elements in ore processing, benefit from rigorous testing and innovation in screen metal sheet design and manufacturing. In conclusion, investing in screen metal sheets involves more than a purchase transaction; it's an informed decision-making process driven by expertise and an understanding of environmental impact, budget, and technical requirements. The right choice hinges on comprehensive evaluation and guidance from knowledgeable professionals who ensure that every sheet matches specific project needs, thus fostering sustainable and efficient usage. The longevity, efficiency, and functionality of projects across diverse industries undeniably reflect the thoughtfulness embedded in selecting the right screen metal sheet.

Authoritative sourcing of screen metal sheets is essential. Reputable manufacturers adhere to strict quality controls and industry standards, ensuring sheets stand up to specified loads, wear, and environmental exposure. They provide technical datasheets, which novice and veteran users alike can trust for information on mechanical properties, chemical compositions, and recommended application uses. Such authoritative data is indispensable for ensuring both safety and longevity in usage. From a trustworthiness perspective, the quality of screen metal sheets extends beyond manufacturing and material selection. It incorporates handling, installation, and maintenance practices. Improper installation can lead to structural failures and loss of efficiency, whereas regular maintenance—such as cleaning and corrosion protection—ensures the prolonged service life of these metal sheets. Feedback from industries using screen metal sheets showcases their reliability and efficiency across various applications. Sectors ranging from agriculture, where screens are used to sort grains and protect against pests, to mining, where they serve as crucial sieving elements in ore processing, benefit from rigorous testing and innovation in screen metal sheet design and manufacturing. In conclusion, investing in screen metal sheets involves more than a purchase transaction; it's an informed decision-making process driven by expertise and an understanding of environmental impact, budget, and technical requirements. The right choice hinges on comprehensive evaluation and guidance from knowledgeable professionals who ensure that every sheet matches specific project needs, thus fostering sustainable and efficient usage. The longevity, efficiency, and functionality of projects across diverse industries undeniably reflect the thoughtfulness embedded in selecting the right screen metal sheet.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP