Understanding Round Perforated Sheets Versatility and Applications

Round perforated sheets are an essential component in various industries and applications due to their unique properties and functionality. These sheets, characterized by their round holes produced through a perforation process, serve a multitude of purposes ranging from filtration to aesthetic design.

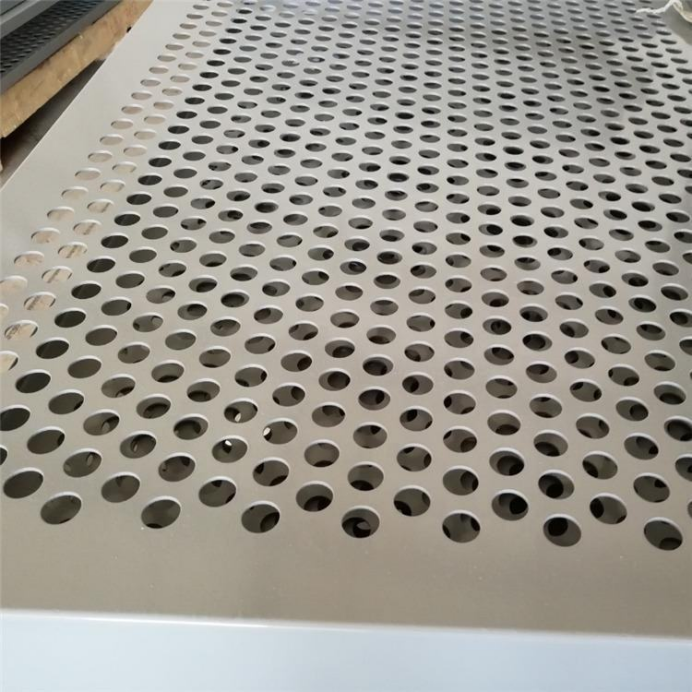

What Are Round Perforated Sheets?

Round perforated sheets are metal or plastic sheets that feature a pattern of circular holes. These holes can vary in size, spacing, and pattern based on the specific requirements of the application. The manufacturing process typically involves the use of specialized machinery that punches holes into the sheet, creating a precise and uniform pattern.

Materials Used

The materials for round perforated sheets can range from stainless steel and aluminum to plastic composites, each chosen based on the application needs. Stainless steel is favored for its corrosion resistance and durability, making it ideal for outdoor applications or environments where moisture is a concern. Aluminum, being lightweight, is often used in situations where weight is a critical factor. Plastic perforated sheets, on the other hand, provide a cost-effective solution for indoor applications or environments where chemical resistance is important.

Applications of Round Perforated Sheets

The versatility of round perforated sheets enables their use across a wide range of industries. Below are some key applications

round perforated sheet

1. Filtration In many industrial processes, round perforated sheets are utilized as filters. The precise size and spacing of holes allow for effective separation of solids from liquids or air, making them essential components in water treatment plants, HVAC systems, and food processing.

2. Architectural Design Beyond functionality, round perforated sheets are increasingly used in architectural designs. They can create visually appealing facades, privacy screens, and interior design elements while allowing light and air to pass through. This aesthetic flexibility makes them popular in modern architectural projects.

3. Sound Dampening In acoustics, round perforated sheets help in sound absorption. Their design can be engineered to reduce noise levels in environments such as offices, auditoriums, and recording studios. The configuration of holes alters sound waves, providing a quieter atmosphere.

4. Safety and Security Round perforated sheets are also used in manufacturing guards and protective covers. Their solid structure combined with perforations allows visibility while providing necessary protection for machinery and personnel in various manufacturing settings.

5. Agriculture In agricultural settings, these sheets can serve as grates or platforms for drying crops or processing materials. The round holes facilitate airflow, which is crucial in preventing spoilage and enhancing efficiency.

Conclusion

Round perforated sheets are a prime example of how simple design can yield significant utility across diverse fields. Their applications highlight the blend of functionality and aesthetics, showing that they are not just about practicality, but also about enhancing the design and effectiveness of spaces. As industries continue to innovate, the role of round perforated sheets will likely evolve, adapting to new challenges and requirements. Whether in filtration, architecture, acoustics, or security, these sheets prove to be indispensable tools that meet the needs of modern applications effectively.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.