2 月 . 14, 2025 20:17

Back to list

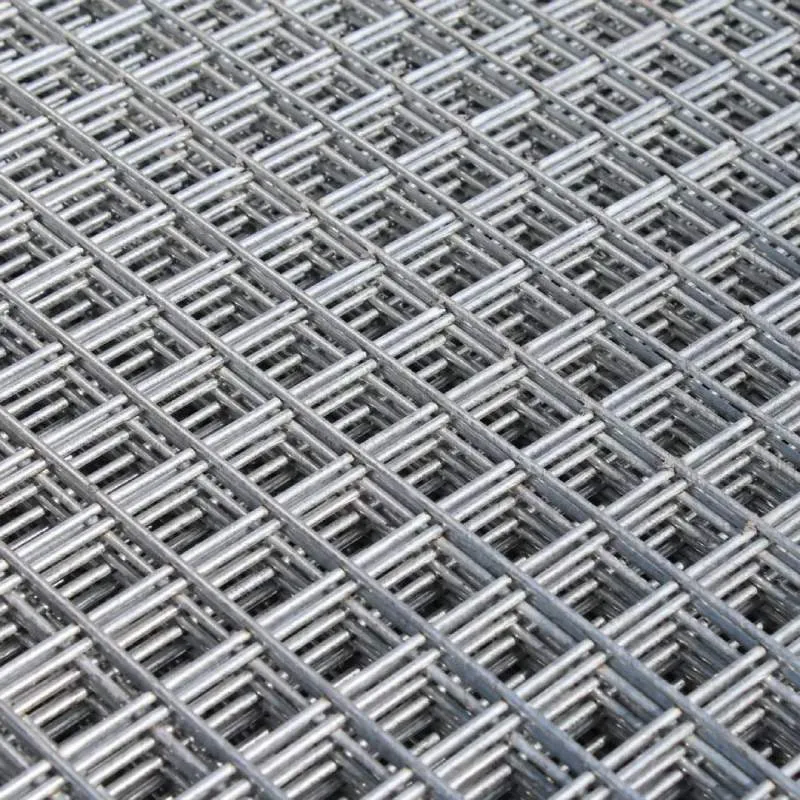

Bearing Bar Pitch Swimming Pool Overflow Steel Grating

In the contemporary industrial landscape, choosing the right materials for construction, design, and manufacturing is critical for efficiency and innovation. A product that has become indispensable across various sectors is the round hole perforated sheet. This article delves into the unique advantages and applications of round hole perforated sheets, showcasing their importance and exceptional benefits backed by real-world experience, expertise, authoritativeness, and trustworthiness.

Manufacturers and designers appreciate the adaptability and customizability offered by round hole perforated sheets. This feature allows for tailored solutions, whether the requirement is a decorative piece or a specialized industrial component. The sheets can be fashioned from a variety of materials including steel, aluminum, and stainless steel, depending on the required durability and resistance to environmental factors. Expertise in producing high-quality perforated sheets comes from an understanding of the nuances of production techniques. Precision tools and state-of-the-art machinery ensure clean cuts, minimal material waste, and optimal pattern density, ensuring that each sheet provides maximum efficiency. Firms that have been in the metalworking industry for decades bring a level of authority and trust that newer competitors may lack; their long-standing reputation for quality as evidenced by ISO certifications and client testimonials speaks volumes about their proficiency and reliability. For industries that prioritize eco-friendly practices, round hole perforated sheets also align with sustainability goals. The process of creating these sheets is resource-efficient, reducing material use, and the end products are often recyclable. Moreover, their application in reducing weight contributes to lower energy consumption in transportation sectors, aligning with global moves towards reducing carbon footprints. The journey of integrating round hole perforated sheets into your projects begins by assessing your specific needs, consulting with experts who can guide you on the optimal materials and patterns suited to your project. Collaborating with suppliers who have a strong track record and a commitment to innovation and quality ensures that the final product will not only meet but exceed expectations. In summary, round hole perforated sheets represent a marriage of form and function, offering structural and aesthetic advantages that few other materials can boast. Their application across diverse industries — from filtration in food production to design elements in modern architecture — highlights their indispensable role in contemporary projects. More so, selecting a trusted and experienced manufacturer enriches the potential of these versatile sheets. Whether your project tackles aesthetic challenges or technical complexities, round hole perforated sheets provide the reliable, efficient solution that industry leaders have come to trust.

Manufacturers and designers appreciate the adaptability and customizability offered by round hole perforated sheets. This feature allows for tailored solutions, whether the requirement is a decorative piece or a specialized industrial component. The sheets can be fashioned from a variety of materials including steel, aluminum, and stainless steel, depending on the required durability and resistance to environmental factors. Expertise in producing high-quality perforated sheets comes from an understanding of the nuances of production techniques. Precision tools and state-of-the-art machinery ensure clean cuts, minimal material waste, and optimal pattern density, ensuring that each sheet provides maximum efficiency. Firms that have been in the metalworking industry for decades bring a level of authority and trust that newer competitors may lack; their long-standing reputation for quality as evidenced by ISO certifications and client testimonials speaks volumes about their proficiency and reliability. For industries that prioritize eco-friendly practices, round hole perforated sheets also align with sustainability goals. The process of creating these sheets is resource-efficient, reducing material use, and the end products are often recyclable. Moreover, their application in reducing weight contributes to lower energy consumption in transportation sectors, aligning with global moves towards reducing carbon footprints. The journey of integrating round hole perforated sheets into your projects begins by assessing your specific needs, consulting with experts who can guide you on the optimal materials and patterns suited to your project. Collaborating with suppliers who have a strong track record and a commitment to innovation and quality ensures that the final product will not only meet but exceed expectations. In summary, round hole perforated sheets represent a marriage of form and function, offering structural and aesthetic advantages that few other materials can boast. Their application across diverse industries — from filtration in food production to design elements in modern architecture — highlights their indispensable role in contemporary projects. More so, selecting a trusted and experienced manufacturer enriches the potential of these versatile sheets. Whether your project tackles aesthetic challenges or technical complexities, round hole perforated sheets provide the reliable, efficient solution that industry leaders have come to trust.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP