2 月 . 14, 2025 21:15

Back to list

Sound Proof Fence Panels China Factory Sound Proof Barrier 2460*500*80mm Viaduct Sound Barrier

Exploring the Versatility and Benefits of Round Hole Perforated Metal for Modern Industries

Durability and longevity are also cornerstones of round hole perforated metal's appeal. Metals like stainless steel and aluminum naturally resist corrosion, and when combined with the customizability of the perforation pattern, these sheets provide long-lasting solutions in harsh environmental conditions. This makes them ideal for use in outdoor installations and challenging industrial settings, where resilience is essential. From an engineering standpoint, the customizable nature of perforated metal allows for a level of specificity tailored to each application’s unique requirements. By adjusting the diameter, spacing, and arrangement of the holes, manufacturers can influence air or liquid flow rates, sound insulation properties, and even the structural weight of the metals. This ability to fine-tune specifications opens up endless possibilities for innovation in manufacturing processes. Furthermore, the environmental efficiency of round hole perforated metal cannot be overlooked. The production process typically generates minimal waste, and most of the base metals are recyclable, which aligns with global sustainability goals. Industries are increasingly prioritizing sustainable manufacturing, and the eco-friendly nature of perforated metal plays into this narrative, bolstering its reputation as a responsible choice in material selection. Finally, the customer service and support associated with round hole perforated metal suppliers often reflect high levels of expertise and professionalism. Leading manufacturers invest in personnel who understand the technical specifications and application requirements of their products, which instills confidence and trust in consumers. Whether for bespoke designs or large-scale industrial applications, purchasers can rely on knowledgeable support for advice and implementation strategies. In conclusion, round hole perforated metal's integration across various industries is a testament to its unmatched versatility and utility. As the demand for innovative, sustainable, and aesthetically pleasing materials continues to grow, the role of this perforated metal is set to expand further, marking it as a key player in the future of material science and industrial design.

Durability and longevity are also cornerstones of round hole perforated metal's appeal. Metals like stainless steel and aluminum naturally resist corrosion, and when combined with the customizability of the perforation pattern, these sheets provide long-lasting solutions in harsh environmental conditions. This makes them ideal for use in outdoor installations and challenging industrial settings, where resilience is essential. From an engineering standpoint, the customizable nature of perforated metal allows for a level of specificity tailored to each application’s unique requirements. By adjusting the diameter, spacing, and arrangement of the holes, manufacturers can influence air or liquid flow rates, sound insulation properties, and even the structural weight of the metals. This ability to fine-tune specifications opens up endless possibilities for innovation in manufacturing processes. Furthermore, the environmental efficiency of round hole perforated metal cannot be overlooked. The production process typically generates minimal waste, and most of the base metals are recyclable, which aligns with global sustainability goals. Industries are increasingly prioritizing sustainable manufacturing, and the eco-friendly nature of perforated metal plays into this narrative, bolstering its reputation as a responsible choice in material selection. Finally, the customer service and support associated with round hole perforated metal suppliers often reflect high levels of expertise and professionalism. Leading manufacturers invest in personnel who understand the technical specifications and application requirements of their products, which instills confidence and trust in consumers. Whether for bespoke designs or large-scale industrial applications, purchasers can rely on knowledgeable support for advice and implementation strategies. In conclusion, round hole perforated metal's integration across various industries is a testament to its unmatched versatility and utility. As the demand for innovative, sustainable, and aesthetically pleasing materials continues to grow, the role of this perforated metal is set to expand further, marking it as a key player in the future of material science and industrial design.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

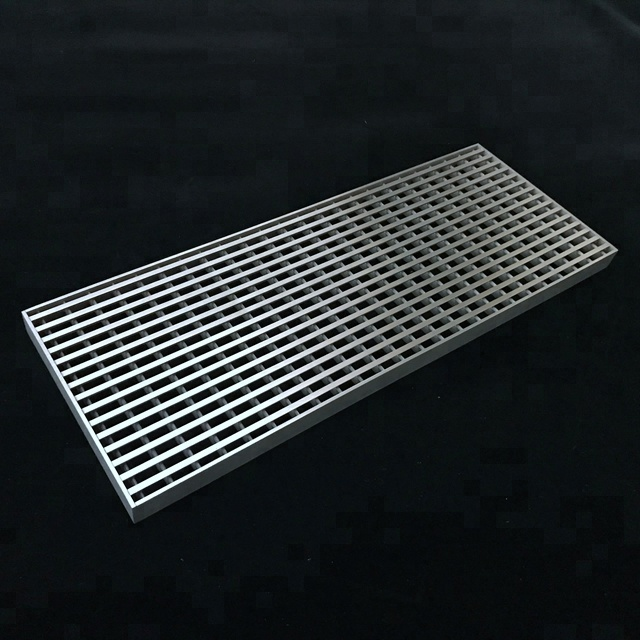

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP