The Versatility and Applications of Punched Metal Sheets

Punched metal sheets, also known as perforated sheets, are a type of metal material that has been mechanically stamped or punched to create a series of holes, patterns, or designs. These sheets are made from a variety of materials including aluminum, stainless steel, and mild steel, making them suitable for a wide range of applications across different industries. The beauty of punched metal sheets lies not only in their functionality but also in their aesthetic appeal, as the patterns can be tailored to a specific design while still providing structural integrity.

Manufacturing Process

The manufacturing process of punched metal sheets involves several steps. Initially, a flat sheet of metal is selected based on the desired characteristics such as thickness, durability, and surface finish. The next step involves using a punching machine, which employs a die and punch to create holes or patterns in the metal sheet. This process can be customized to achieve various hole sizes, shapes, and spacing, giving designers and architects the freedom to create unique designs that meet their specific needs.

The ability to create intricate patterns adds to the attractiveness of punched metal sheets. From simple geometric patterns to complex designs, the flexibility in design allows for creativity in architectural projects and decorative uses. Moreover, advancements in technology have made it possible to produce even more precise and complex patterns, further enhancing the variety available in the market.

Applications

Punched metal sheets boast a broad range of applications across various industries

1. Architecture and Construction In architecture, punched metal sheets are widely used for facades, sunshades, and railings. These sheets not only provide necessary structural support but also serve aesthetic purposes by allowing light and air to filter through. The patterns can also contribute to reducing heat gain, making buildings more energy-efficient.

punched metal sheets

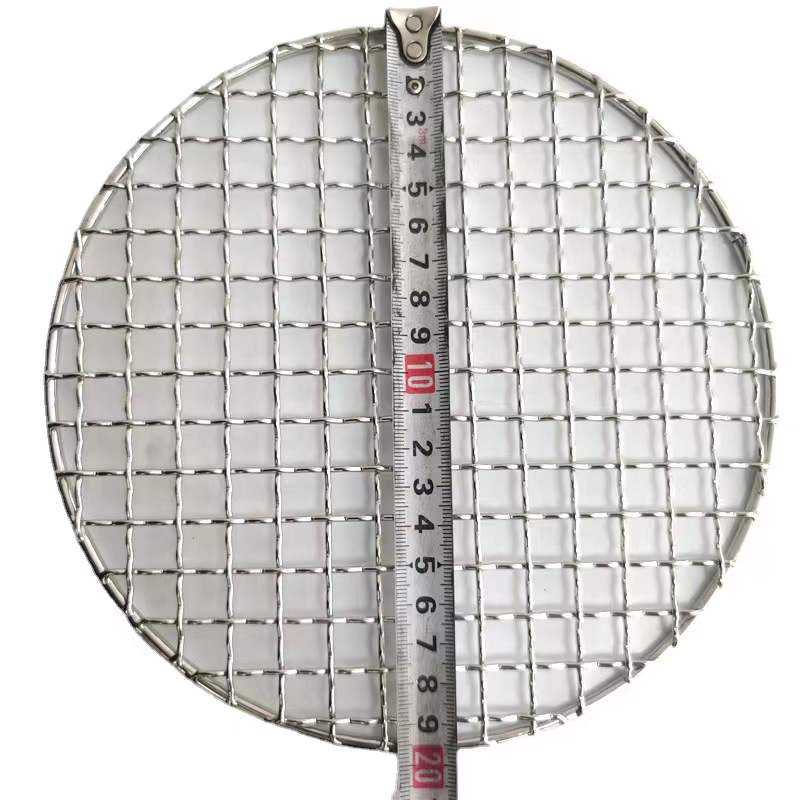

2. Industrial Uses The industrial sector employs punched metal sheets in the production of filters, baskets, and protective guards. For instance, perforated sheets are used in air and liquid filtration systems, providing essential performance while allowing for the flow of fluids or gases.

3. Interior Design Punched metal sheets with decorative patterns are increasingly being used in interior spaces. From feature walls to ceiling fixtures, these sheets can add a modern and stylish flair. Their versatility makes them suitable for both residential and commercial spaces, enhancing the overall aesthetic.

4. Automotive and Aerospace In the automotive and aerospace industries, punched metal sheets are utilized for various components, including grills, heat shields, and chassis. The lightweight nature of perforated sheets can contribute to overall weight reduction, which is crucial for fuel efficiency and performance.

Benefits of Punched Metal Sheets

The use of punched metal sheets comes with a multitude of benefits. Firstly, their lightweight nature makes them easier to handle and install compared to solid sheets. Secondly, they exhibit strength and durability, which allows them to withstand various environmental conditions. Additionally, the perforation aids in ventilation, reducing the weight of materials without compromising strength.

Another significant advantage is their cost-effectiveness. Punched metal sheets can be produced efficiently, reducing waste and labor costs during manufacturing. This efficiency translates to lower prices for end-users while maintaining high standards of quality.

Conclusion

In conclusion, punched metal sheets hold a pivotal role in modern manufacturing and design, catering to a myriad of applications across diverse industries. Their combination of functionality, strength, and aesthetic appeal makes them an invaluable resource for architects, designers, and engineers alike. As technology continues to advance, the potential for innovation in punched metal sheets remains vast, promising even more diverse applications and creative possibilities in the future. Whether for structural support, decorative elements, or industrial uses, punched metal sheets undoubtedly represent a fusion of art and engineering that shapes our environments.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.