The Versatility and Applications of Punched Metal Plates

Punched metal plates are an essential component in a variety of industries, thanks to their unique properties and applications. These plates, manufactured by utilizing a process that involves punching holes into metal sheets, offer a balance of strength and aesthetic appeal. The versatility of punched metal plates makes them a popular choice in construction, automotive, aerospace, and many other sectors.

Manufacturing Process

The production of punched metal plates begins with a flat sheet of metal, which can be made from various materials, including steel, aluminum, and brass. The desired pattern is created using a punch press, which applies high pressure to punch holes through the metal sheet. This process can create various patterns and shapes, from simple circles to more intricate designs, depending on the needs of the application.

The punched metal plate can undergo secondary processes such as sanding, welding, or powder coating to enhance its functionality or appearance. This flexibility in manufacturing allows for customized solutions tailored to meet specific requirements.

Applications in Construction

One of the primary industries where punched metal plates are utilized is construction. These plates are often used for architectural applications, such as facades, partitions, and ceiling designs. Their perforated nature allows for light and sound diffusion while maintaining structural integrity, making them an excellent choice for both aesthetic and functional purposes.

In addition, punched metal plates provide ventilation in various systems, including heating, ventilation, and air conditioning (HVAC) systems. The carefully designed holes allow for adequate airflow while preventing ingress of larger debris, thus ensuring efficient operation.

Automotive and Aerospace Industries

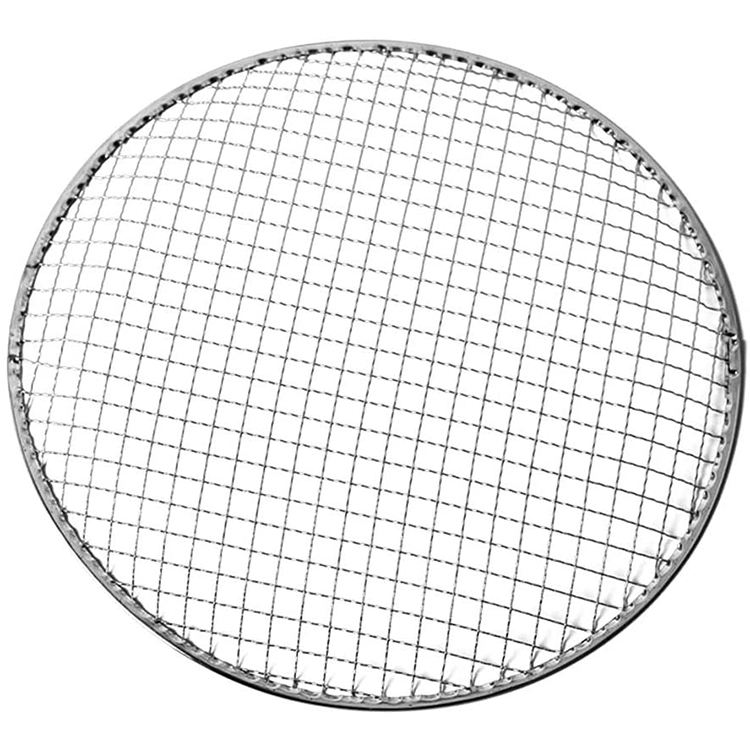

punched metal plate

In the automotive sector, punched metal plates are extensively used for manufacturing grille covers, engine guards, and decorative elements. Their lightweight yet durable characteristics contribute to fuel efficiency and performance, making them a favored choice among manufacturers.

Similarly, the aerospace industry benefits from the use of punched metal plates. They are often used in the fabrication of components for aircraft, where weight reduction is crucial. Punched plates are manufactured using materials such as titanium and aluminum, which provide the necessary strength without excessive weight, contributing to fuel efficiency and optimal performance.

Artistic Applications

Beyond their practical uses, punched metal plates have also found a niche in the art world. Artists and designers have begun to explore the aesthetic possibilities of these materials, creating visually striking pieces that can transform public spaces, homes, and commercial establishments. The interplay of light and shadow created by the punched patterns can give rise to dynamic visual effects, further enhancing the artistic value of the plates.

Environmental Considerations

With an increasing focus on sustainability, punched metal plates can be a more environmentally friendly option compared to other materials. They can be manufactured from recycled metals, and their long lifespan reduces the need for frequent replacements, conserving resources. Additionally, their energy-efficient manufacturing process helps lower the carbon footprint.

Conclusion

Punched metal plates represent a unique intersection of functionality, aesthetics, and sustainability. Their diverse applications across various industries highlight their significance in modern manufacturing. As technology advances and designs become more sophisticated, the potential for punched metal plates continues to expand. Whether in construction, automotive design, aerospace engineering, or artistic creations, these plates are poised to remain a vital element of innovation for years to come. Their combination of durability, versatility, and visual appeal ensures that they will continue to find new applications in our ever-evolving world.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.