1 月 . 30, 2025 05:23

Back to list

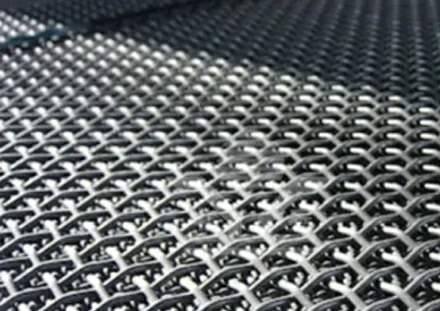

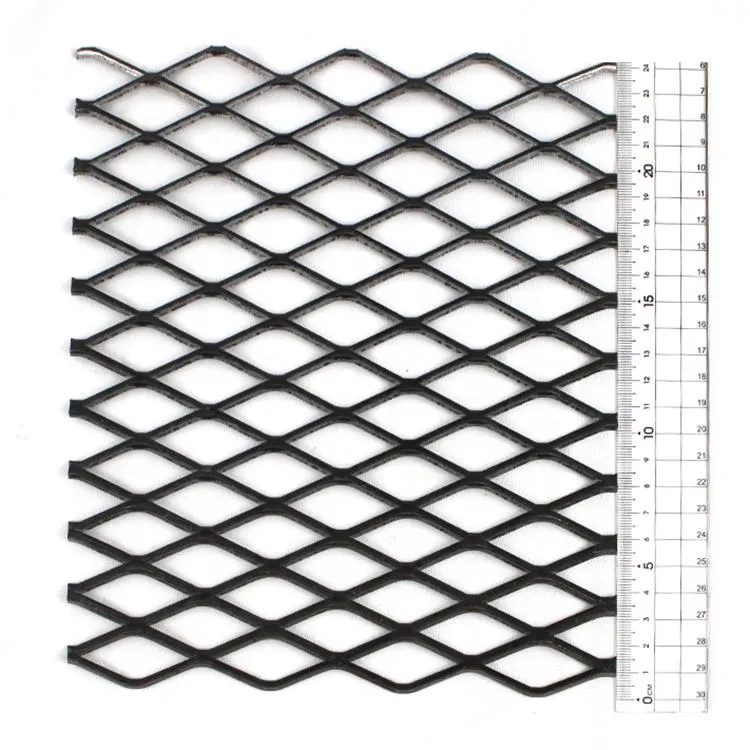

Heavy expanded metal mesh

Platform steel grating stands as an indispensable component across various industrial applications, revered for its robust performance and unmatched versatility. Its applications span many sectors, including construction, manufacturing, and transport. This article delves into the key qualities that make platform steel grating a preferred choice, substantiated through real-world experiences, and backed by practical expertise, to highlight its authoritative standing in the marketplace.

What further solidifies the authoritative nature of platform steel grating is its compliance with global safety and quality standards. Esteemed certifying bodies regularly assess and certify these products, providing assurance to stakeholders. In addition, advanced coating technologies, such as galvanization, extend the lifespan of steel gratings by offering superior protection against rust and corrosion. Testimonies from facility managers assert that such innovations have rendered maintenance operations more cost-effective, contributing to the economic feasibility of using steel gratings over alternatives like wood or composite materials. In the context of trustworthiness, platform steel grating's widespread adoption across critical infrastructure projects speaks volumes. It is favored by government bodies in urban development projects due to its reliability and safety features. When asked about their material choice for a large-scale public park project, municipal planners highlighted steel grating's robust nature and minimal upkeep. This choice is consistent with an industry trend that prioritizes sustainability and lasting infrastructure investments. In summary, platform steel grating's esteemed status in the industrial realm is no accident; it is a convergence of solid empirical experience, deep-rooted expertise, authoritative adherence to industry norms, and a credible track record of enhancing workplace safety and functionality. As industries continually evolve and demand materials that promise performance and reliability, platform steel grating stands unwavering—a testament to engineering prowess and innovation. Businesses seeking durable, efficient, and reliable solutions would benefit immensely from integrating platform steel grating into their infrastructure, fostering not only operational efficiency but also peace of mind.

What further solidifies the authoritative nature of platform steel grating is its compliance with global safety and quality standards. Esteemed certifying bodies regularly assess and certify these products, providing assurance to stakeholders. In addition, advanced coating technologies, such as galvanization, extend the lifespan of steel gratings by offering superior protection against rust and corrosion. Testimonies from facility managers assert that such innovations have rendered maintenance operations more cost-effective, contributing to the economic feasibility of using steel gratings over alternatives like wood or composite materials. In the context of trustworthiness, platform steel grating's widespread adoption across critical infrastructure projects speaks volumes. It is favored by government bodies in urban development projects due to its reliability and safety features. When asked about their material choice for a large-scale public park project, municipal planners highlighted steel grating's robust nature and minimal upkeep. This choice is consistent with an industry trend that prioritizes sustainability and lasting infrastructure investments. In summary, platform steel grating's esteemed status in the industrial realm is no accident; it is a convergence of solid empirical experience, deep-rooted expertise, authoritative adherence to industry norms, and a credible track record of enhancing workplace safety and functionality. As industries continually evolve and demand materials that promise performance and reliability, platform steel grating stands unwavering—a testament to engineering prowess and innovation. Businesses seeking durable, efficient, and reliable solutions would benefit immensely from integrating platform steel grating into their infrastructure, fostering not only operational efficiency but also peace of mind.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP