Understanding Platform Steel Grating A Comprehensive Overview

Platform steel grating is a versatile and essential component in various industrial applications. It serves not only as a functional element but also enhances safety and efficiency in workplaces. This article will explore the significance of platform steel grating, its types, applications, benefits, and maintenance practices.

What is Platform Steel Grating?

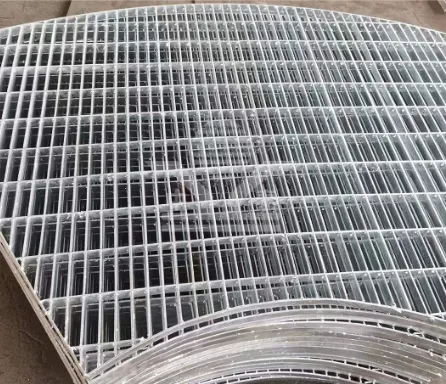

Platform steel grating refers to a series of metal bars arranged in a grid pattern, creating a surface that allows for the easy passage of light, air, and water while providing a robust walking or loading platform. Typically manufactured from carbon steel, stainless steel, or aluminum, these gratings play a crucial role in industrial platforms, walkways, and staircases.

Types of Steel Grating

There are several types of steel grating, with the most commonly used being

1. Welded Steel Grating Made by welding cross bars to bearing bars, this type offers high load capacities and is ideal for heavy-duty applications. 2. Press-locked Grating Involves pressing the bearing bars and cross bars together without welding. This results in a lighter and more cost-effective alternative that still maintains good strength.

3. Swaged Grating Features bars that are swaged together for a tightly interlocked structure. This type is especially solid and suitable for areas with heavy traffic.

4. Trench Grating Specifically designed to cover trench drainage systems, allowing for efficient drainage while providing a flat surface for pedestrian traffic.

Applications of Platform Steel Grating

The applications of platform steel grating are extensive, spanning across multiple industries

- Industrial Plants In manufacturing facilities, steel grating serves as flooring for platforms and walkways, supporting machinery and heavy equipment. - Oil & Gas Industry Commonly used in offshore platforms and refineries, steel grating ensures safe walkways in environments exposed to hazardous materials.

- Water Treatment Facilities Provides durable walking surfaces above water channels, allowing for easy access for maintenance and monitoring.

- Construction and Architecture Used in designing aesthetically pleasing features such as balcony floors and stair treads, combining functionality with style.

platform steel grating

Benefits of Platform Steel Grating

1. Safety The open design of steel grating allows for excellent drainage, reducing the risk of slip hazards on slippery surfaces.

2. Durability Steel gratings are resistant to impact and wear, making them ideal for high-traffic areas. With proper maintenance, they can last decades.

3. Customizability They can be fabricated to meet specific requirements regarding size, load capacity, and surface treatment (like galvanization), ensuring that they meet the unique needs of each project.

4. Environmentally Friendly Steel is 100% recyclable, making platform steel grating a sustainable choice for construction and industrial applications.

Maintenance Practices

To ensure the longevity and safety of platform steel grating, regular maintenance is essential

- Inspection Conduct periodic inspections to identify signs of wear, corrosion, or damage. This should include checking for loose or missing grating sections.

- Cleaning Regular cleaning prevents the accumulation of debris that can retain moisture and cause corrosion. High-pressure washing can be utilized to maintain a clear and safe surface.

- Surface Treatments Applying protective coatings or paints can enhance the corrosion resistance of steel gratings, particularly in corrosive environments.

- Replacing Damaged Grating Promptly replacing any damaged sections ensures the structural integrity and safety of the entire platform.

Conclusion

Platform steel grating is an indispensable component in various industries, offering safety, durability, and functionality. Understanding its types, applications, benefits, and maintenance practices allows businesses to make informed decisions when integrating steel grating into their infrastructures. With the proper implementation and upkeep, platform steel grating can significantly contribute to a safe and efficient working environment.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.