The Versatility and Applications of Pierced Metal Sheets

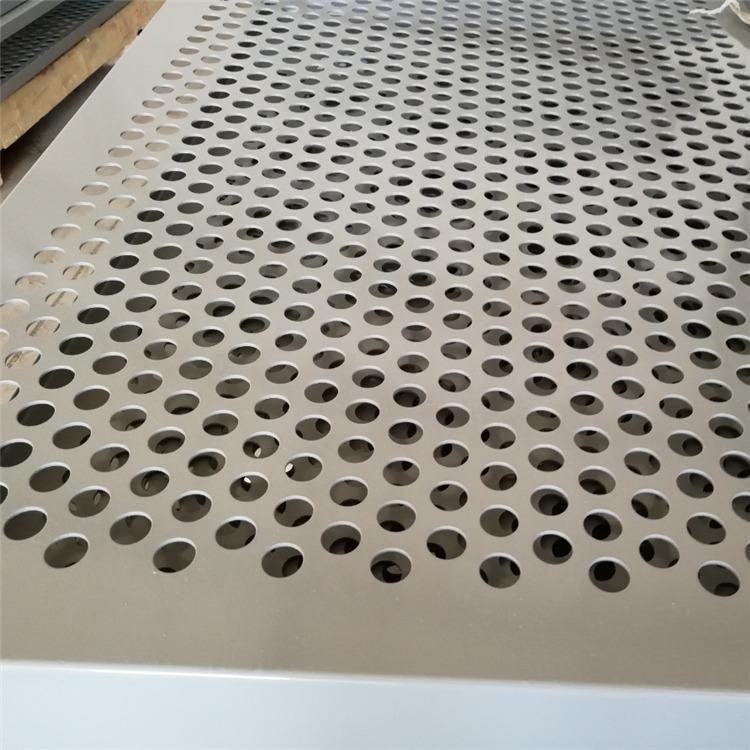

Pierced metal sheets, often referred to as perforated metal, have found their way into numerous industries due to their unique blend of strength, durability, and aesthetic appeal. These sheets are characterized by a series of holes or slots punched into the metal, which can vary in shape, size, and pattern according to specific design requirements. The process of perforation not only enhances the functionality of the metal but also contributes to its visual charm, making it suitable for both practical applications and artistic endeavors.

Manufacturing Process

The creation of pierced metal sheets involves a precise manufacturing process. The sheets are typically made from various types of metals including stainless steel, aluminum, and brass. The perforating process can be achieved through different techniques such as punching, laser cutting, or water jet cutting. The choice of method depends on the desired hole geometry, material thickness, and production volume.

After perforation, the sheets can undergo additional processes such as deburring, which smooths out sharp edges, and coating, which provides protective finishes and enhances appearance. These enhancements further increase the durability of the metal, making pierced sheets resistant to corrosion and wear, which is essential for many industrial applications.

Applications in Architecture and Design

One of the most prominent applications of pierced metal sheets is in architecture and design

. They are often utilized in facades, canopies, and screens to provide both functionality and aesthetics. Architects and designers appreciate the ability of perforated sheets to allow natural light and air to flow through while maintaining a degree of privacy and shielding against external elements. For instance, a perforated metal facade can reduce solar heat gain while creating stunning visual effects, especially when illuminated at night.pierced metal sheets

Moreover, these sheets are frequently used in interior design as decorative elements, including feature walls and room dividers. The variety of patterns available can be tailored to fit specific design themes, adding texture and depth to spaces without overwhelming them. From contemporary settings to industrial chic styles, pierced metal sheets cater to diverse tastes and applications.

Industrial Uses

Beyond aesthetics, pierced metal sheets are essential in various industrial applications. In the manufacturing sector, they are employed in filtration systems, where the perforations allow fluid to pass through while trapping solid particles. This is crucial in industries like food processing, pharmaceuticals, and chemical manufacturing, where precise filtration is vital for product quality and safety.

In the automotive industry, perforated metal is used in the production of components such as heat shields and grilles. These parts require a balance of strength and lightweight properties, making pierced sheets an ideal choice. Additionally, they are utilized in sound attenuation applications, helping to reduce noise pollution in engines and machinery.

Conclusion

The versatility of pierced metal sheets makes them an essential element across various domains. Their ability to combine functional properties with aesthetic appeal allows them to be integrated into everything from massive architectural structures to intricate interior designs. Moreover, their indispensable role in industries highlights the importance of innovation in manufacturing processes to cater to evolving demands.

As industries and design trends continue to advance, the potential applications of pierced metal sheets will undoubtedly expand, leading to new opportunities for creativity and efficiency. Whether enhancing a building’s facade or improving the functionality of industrial equipment, pierced metal sheets represent a powerful synthesis of art and engineering, marking their significance in the modern world.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.