2 月 . 14, 2025 12:49

Back to list

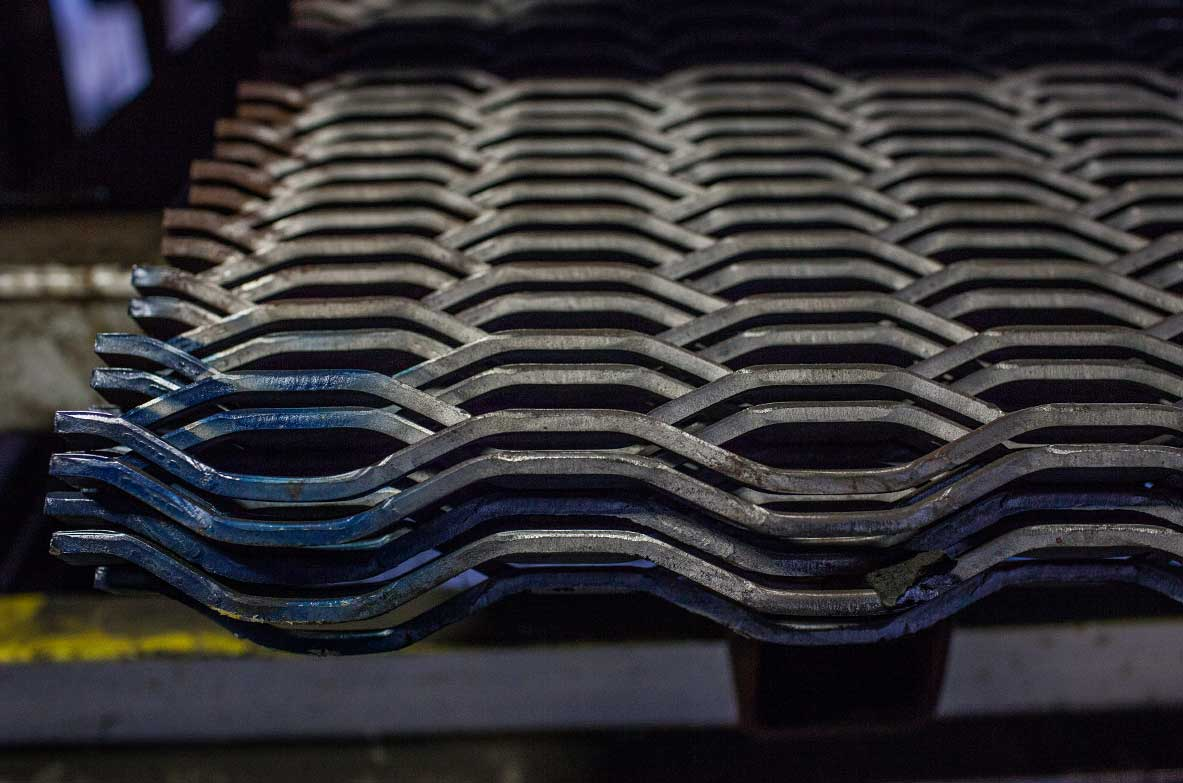

perforated steel sheet 5mm thick

Perforated steel sheets, with a thickness of 5mm, are remarkably versatile and invaluable across numerous industries due to their unique combination of strength, durability, and functionality. These sheets are engineered with precision, making them ideal for applications ranging from architecture to industrial processes, enhancing both the aesthetic and functional aspects of projects.

Trustworthiness in the context of perforated steel sheets is built through consistent performance and the assurance of safety and longevity offered to users. These sheets undergo rigorous quality control measures during manufacturing, ensuring they meet industry standards and regulations. Users can trust the durability of 5mm thick perforated steel sheets in demanding environments such as automotive assemblies, where the sheets are used for parts that require both strength and precision. Over time, these products have proven their capability to withstand harsh conditions without compromising on quality, which is why engineers and designers consistently return to them for new projects. In ecological terms, 5mm perforated steel sheets contribute positively to sustainable practices. Steel is one of the world's most recyclable materials, meaning that using these sheets supports efforts towards reducing environmental impact. Their strength ensures longevity, reducing the need for frequent replacements and thus decreasing waste. Furthermore, their application in energy-efficient projects, such as environmentally conscious building designs, speaks volumes of their adaptability and enduring relevance in modern green standards. In conclusion, 5mm thick perforated steel sheets offer an outstanding balance of functionality and form, tailored for a wide range of applications. Their enduring presence across industries is a testament to their unmatched quality in delivering structural support, aesthetic enhancement, and sustainable solutions. Embracing these steel sheets ensures that architects, engineers, and industrial designers have reliable tools at their disposal to innovate and push boundaries in their respective fields.

Trustworthiness in the context of perforated steel sheets is built through consistent performance and the assurance of safety and longevity offered to users. These sheets undergo rigorous quality control measures during manufacturing, ensuring they meet industry standards and regulations. Users can trust the durability of 5mm thick perforated steel sheets in demanding environments such as automotive assemblies, where the sheets are used for parts that require both strength and precision. Over time, these products have proven their capability to withstand harsh conditions without compromising on quality, which is why engineers and designers consistently return to them for new projects. In ecological terms, 5mm perforated steel sheets contribute positively to sustainable practices. Steel is one of the world's most recyclable materials, meaning that using these sheets supports efforts towards reducing environmental impact. Their strength ensures longevity, reducing the need for frequent replacements and thus decreasing waste. Furthermore, their application in energy-efficient projects, such as environmentally conscious building designs, speaks volumes of their adaptability and enduring relevance in modern green standards. In conclusion, 5mm thick perforated steel sheets offer an outstanding balance of functionality and form, tailored for a wide range of applications. Their enduring presence across industries is a testament to their unmatched quality in delivering structural support, aesthetic enhancement, and sustainable solutions. Embracing these steel sheets ensures that architects, engineers, and industrial designers have reliable tools at their disposal to innovate and push boundaries in their respective fields.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP