2 月 . 11, 2025 18:44

Back to list

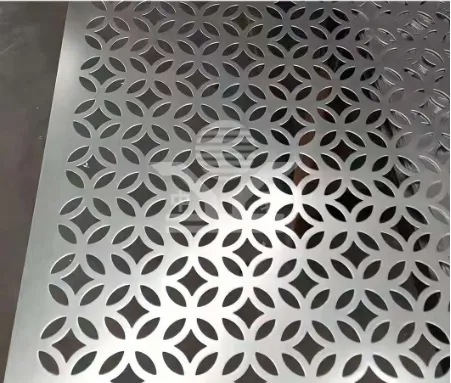

perforated stainless steel screen

Perforated stainless steel screens have revolutionized various industries by offering durability, versatility, and precision in their applications. These screens, crafted from high-quality stainless steel, deliver unmatched performance in both industrial and architectural fields. This article delves into the unique attributes of perforated stainless steel screens, underscoring their benefits, practical applications, and why they are considered the gold standard for engineers, architects, and designers.

When it comes to expertise and trustworthiness, the selection of screens from reputable manufacturers is paramount. Leading companies in the field ensure that their products meet rigorous standards and undergo comprehensive testing. Such commitment to quality is reflected in certifications and adherence to international standards, which offer assurance of the screens' performance and reliability. Partnering with a manufacturer that values these principles not only guarantees product excellence but also establishes a foundation of trust and credibility, essential for long-term industrial partnerships. Moreover, the use of perforated stainless steel screens is not limited to large-scale industrial applications. Their practical benefits extend to residential and commercial projects. For instance, in designing modern office spaces, these screens function as partitions or cladding, combining utility with contemporary aesthetics. Their acoustic properties can also contribute to noise reduction in busy environments, further enhancing their versatility and appeal. The future of perforated stainless steel screens holds exciting potential as industries continue to innovate and adapt. Advances in manufacturing technology promise even greater precision and customization capabilities, which will likely expand the applications of these already versatile products. Furthermore, as demand rises for materials that balance performance with minimal environmental impact, perforated stainless steel screens are well-positioned to remain leaders in the market. In conclusion, perforated stainless steel screens embody a union of durability, precision, and sustainability. Their unique attributes not only meet the demands of diverse industries but also align with modern standards of environmental responsibility and aesthetic refinement. As industries evolve, perforated stainless steel continues to prove itself as an essential material, offering solutions that are both elegantly simple and robustly effective. The pursuit of excellence in both product quality and customer satisfaction remains at the forefront, ensuring perforated stainless steel screens retain their esteemed place in the market.

When it comes to expertise and trustworthiness, the selection of screens from reputable manufacturers is paramount. Leading companies in the field ensure that their products meet rigorous standards and undergo comprehensive testing. Such commitment to quality is reflected in certifications and adherence to international standards, which offer assurance of the screens' performance and reliability. Partnering with a manufacturer that values these principles not only guarantees product excellence but also establishes a foundation of trust and credibility, essential for long-term industrial partnerships. Moreover, the use of perforated stainless steel screens is not limited to large-scale industrial applications. Their practical benefits extend to residential and commercial projects. For instance, in designing modern office spaces, these screens function as partitions or cladding, combining utility with contemporary aesthetics. Their acoustic properties can also contribute to noise reduction in busy environments, further enhancing their versatility and appeal. The future of perforated stainless steel screens holds exciting potential as industries continue to innovate and adapt. Advances in manufacturing technology promise even greater precision and customization capabilities, which will likely expand the applications of these already versatile products. Furthermore, as demand rises for materials that balance performance with minimal environmental impact, perforated stainless steel screens are well-positioned to remain leaders in the market. In conclusion, perforated stainless steel screens embody a union of durability, precision, and sustainability. Their unique attributes not only meet the demands of diverse industries but also align with modern standards of environmental responsibility and aesthetic refinement. As industries evolve, perforated stainless steel continues to prove itself as an essential material, offering solutions that are both elegantly simple and robustly effective. The pursuit of excellence in both product quality and customer satisfaction remains at the forefront, ensuring perforated stainless steel screens retain their esteemed place in the market.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP