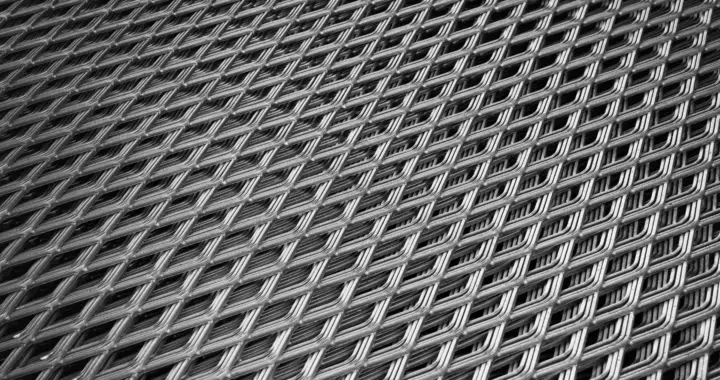

The Versatility of Perforated Stainless Mesh Applications and Benefits

Perforated stainless mesh, a material characterized by its unique combination of durability, flexibility, and aesthetic appeal, is gaining increasing attention across various industries. Made from stainless steel sheets with uniformly spaced holes, this material not only serves practical purposes but also enhances design aesthetics. In this article, we will explore the numerous applications and benefits of perforated stainless mesh, highlighting its significance in both commercial and industrial sectors.

Composition and Manufacturing

Perforated stainless mesh is typically manufactured from high-grade stainless steel, which is known for its resistance to corrosion and oxidative environments. The manufacturing process involves punching or drilling precise holes into sheets of stainless steel, allowing for various hole sizes, shapes, and patterns. This customization means that perforated stainless mesh can be tailored to meet specific requirements, making it suitable for a wide array of applications.

Applications in Various Sectors

1. Architecture and Design One of the most eye-catching applications of perforated stainless mesh is in architecture and interior design. Its aesthetic quality adds a modern touch to buildings, allowing for creative facades, screens, and partitions. Designers utilize the mesh to create skylights, decorative wall panels, and distinctive railings that provide both beauty and functionality.

2. Industrial Uses Perforated stainless mesh is a staple in many industrial processes. Its robust construction makes it ideal for filtration applications, as it allows for the free flow of liquids while effectively trapping larger particles. Industries such as pharmaceuticals, food processing, and water treatment rely on perforated stainless mesh for separating solids from liquids.

3. Transportation The automotive and aerospace sectors also benefit from perforated stainless mesh for various components. It is employed in ventilation systems, sound shielding, and as part of the structural framework. Its lightweight nature, combined with its strength, makes it an ideal choice for manufacturing parts that require both durability and reduced weight.

4. Agriculture In agricultural applications, perforated stainless mesh is used in irrigation systems, drainage solutions, and as protective barriers. Its ability to withstand harsh environmental conditions while providing optimal airflow and water flow makes it essential for modern farming practices.

perforated stainless mesh

5. Furniture and Home Decor The trend of incorporating industrial materials into home decor has led to an increase in the use of perforated stainless mesh in furniture design. Items such as tables, chairs, and shelving units utilize this material not only for its strength but also for its unique visual texture, contributing to a contemporary design aesthetic.

Benefits of Using Perforated Stainless Mesh

- Durability Stainless steel is inherently resistant to rust and corrosion, making perforated stainless mesh a long-lasting solution for various applications.

- Easy Maintenance The smooth surface of perforated stainless steel allows for easy cleaning and maintenance, ensuring that it remains functional and attractive over time.

- Customizability With a variety of hole patterns and sizes available, customers can customize perforated stainless mesh to meet their specific requirements, ensuring that it fits perfectly into the intended application.

- Aesthetic Appeal Beyond functional uses, perforated stainless mesh offers a sleek, modern look that can enhance the visual appeal of any space, making it a preferred choice for architects and designers.

- Sustainability Stainless steel is a recyclable material, contributing to environmentally friendly practices in construction and manufacturing. Choosing perforated stainless mesh can align with sustainability goals.

In conclusion, perforated stainless mesh stands out as a versatile and valuable material across numerous industries. From enhancing architectural beauty to serving critical functions in industrial processes, its applications are both diverse and impactful. As innovation continues, we can expect to see even more creative uses for this remarkable material, solidifying its place as a staple in modern design and manufacturing.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.