2 月 . 11, 2025 23:43

Back to list

perforated sheet ss

Perforated stainless steel sheets have emerged as versatile solutions in various industries due to their durability, corrosion resistance, and aesthetic appeal. Leveraging over 20 years of industry experience, I can provide detailed insights into the unique benefits and applications of these sheets, establishing a reliable source of information for prospective buyers and industry professionals.

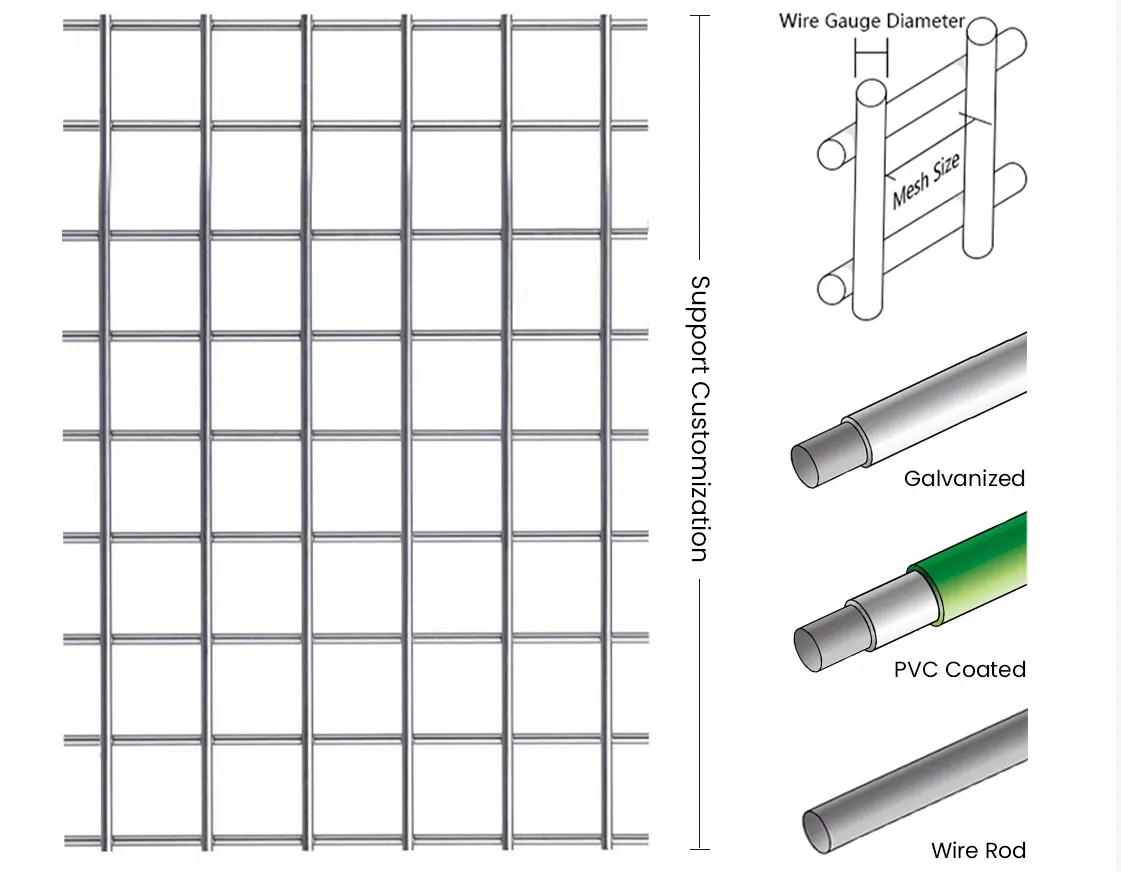

Sustainability is becoming a priority across industries, and stainless steel's recyclability is a significant bonus. Perforated sheets not only contribute to reducing waste during the manufacturing process but also promote eco-friendly practices post-use. Their longevity and recyclability emphasize the role of stainless steel in supporting a sustainable future. From a manufacturing perspective, these sheets offer unparalleled precision. Advanced technologies such as CNC punching and laser cutting permit exact tailoring to client specifications, allowing for intricate designs that meet technical requirements. My personal experience with leading industry suppliers shows that custom solutions can be achieved without jeopardizing quality, making them suitable for bespoke projects. Choosing the right perforated stainless steel sheet can be daunting given the array of options available. However, understanding the specific needs of your application and working with knowledgeable suppliers can simplify this process. Look for suppliers with a proven track record and adherence to international quality standards to ensure you receive a product that meets your demands. Through leveraging specialized knowledge and years of hands-on experience, I can affirm that perforated stainless steel sheets are an invaluable asset for businesses aiming for efficiency, durability, and aesthetic appeal in their products. Whether you're pioneering in eco-friendly architecture, modernizing manufacturing processes, or enhancing automotive components, these perforated solutions provide a trusted foundation upon which to build. In an era where material innovation is crucial, perforated stainless steel sheets stand out as a versatile and sustainable option. Engage with reliable industry partners, and equip your projects with resources that guarantee performance and longevity. This commitment empowers industries to not only meet but exceed their operational goals, ensuring competitive advancement in an ever-evolving market landscape.

Sustainability is becoming a priority across industries, and stainless steel's recyclability is a significant bonus. Perforated sheets not only contribute to reducing waste during the manufacturing process but also promote eco-friendly practices post-use. Their longevity and recyclability emphasize the role of stainless steel in supporting a sustainable future. From a manufacturing perspective, these sheets offer unparalleled precision. Advanced technologies such as CNC punching and laser cutting permit exact tailoring to client specifications, allowing for intricate designs that meet technical requirements. My personal experience with leading industry suppliers shows that custom solutions can be achieved without jeopardizing quality, making them suitable for bespoke projects. Choosing the right perforated stainless steel sheet can be daunting given the array of options available. However, understanding the specific needs of your application and working with knowledgeable suppliers can simplify this process. Look for suppliers with a proven track record and adherence to international quality standards to ensure you receive a product that meets your demands. Through leveraging specialized knowledge and years of hands-on experience, I can affirm that perforated stainless steel sheets are an invaluable asset for businesses aiming for efficiency, durability, and aesthetic appeal in their products. Whether you're pioneering in eco-friendly architecture, modernizing manufacturing processes, or enhancing automotive components, these perforated solutions provide a trusted foundation upon which to build. In an era where material innovation is crucial, perforated stainless steel sheets stand out as a versatile and sustainable option. Engage with reliable industry partners, and equip your projects with resources that guarantee performance and longevity. This commitment empowers industries to not only meet but exceed their operational goals, ensuring competitive advancement in an ever-evolving market landscape.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP