2 月 . 13, 2025 18:56

Back to list

Stainless steel grating

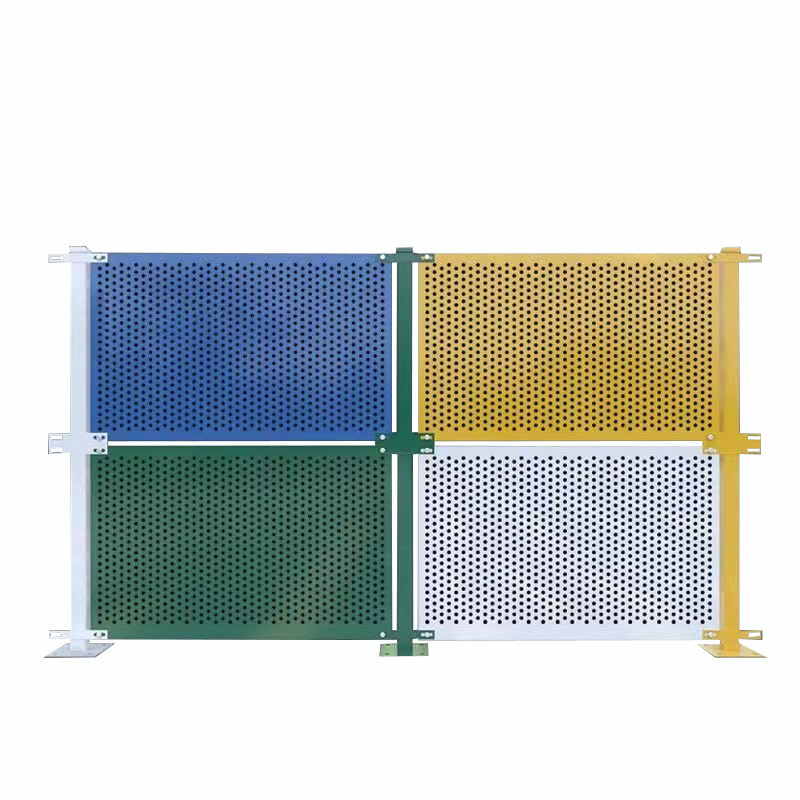

Perforated sheets have rapidly grown in popularity across various industries due to their versatility, durability, and aesthetic appeal. Whether used in architecture, automotive applications, interior design, or industrial processes, these sheets serve multiple purposes. For businesses and consumers seeking high-quality materials, understanding the pricing structure, specifically the cost per kilogram, is crucial.

Several factors influence the price per kilogram of perforated sheets - Material Grade Higher-grade materials often command a higher price due to their enhanced characteristics. - Thickness and Hole Pattern The thickness of the sheet and the density of the perforation pattern can significantly impact the cost. Thicker sheets with intricate patterns require more materials and labor, raising the price. - Manufacturing Process Advanced production techniques can also affect pricing. Precision tooling and technological automation often lead to higher quality sheets but may result in increased costs. Expertise in Selection When selecting the right perforated sheet, it's essential to consult with industry experts. These professionals can provide insights into the best materials and patterns for specific applications, improving performance and cost efficiency. Trustworthy suppliers often offer comprehensive consultation services, ensuring that you make informed decisions tailored to your project needs. Authoritative Sources and Market Trends Market trends show that the demand for perforated sheets is on the rise, driven by architectural innovations and industrial advancements. Authoritative sources such as industry reports from architectural firms and manufacturing associations highlight the growing market and technological advances, making it imperative to choose reputable suppliers with consistent product quality. Building Trust through Transparency Transparent pricing models help build trust with consumers and businesses. Reliable suppliers provide detailed pricing breakdowns, including material costs, labor, and delivery charges. This transparency ensures customers are fully informed about what they are paying for, enhancing trust and establishing long-term business relationships. In conclusion, the perforated sheet market is diverse, with numerous variables impacting the price per kilogram. By considering the material, manufacturing process, and supplier transparency, you can make informed decisions that balance cost and quality. Utilizing the expertise of industry professionals and staying abreast of market trends ensures you capitalize on the best available options for your specific needs. The key to maximizing value lies in thorough research and partnership with credible suppliers committed to providing high-quality perforated sheets.

Several factors influence the price per kilogram of perforated sheets - Material Grade Higher-grade materials often command a higher price due to their enhanced characteristics. - Thickness and Hole Pattern The thickness of the sheet and the density of the perforation pattern can significantly impact the cost. Thicker sheets with intricate patterns require more materials and labor, raising the price. - Manufacturing Process Advanced production techniques can also affect pricing. Precision tooling and technological automation often lead to higher quality sheets but may result in increased costs. Expertise in Selection When selecting the right perforated sheet, it's essential to consult with industry experts. These professionals can provide insights into the best materials and patterns for specific applications, improving performance and cost efficiency. Trustworthy suppliers often offer comprehensive consultation services, ensuring that you make informed decisions tailored to your project needs. Authoritative Sources and Market Trends Market trends show that the demand for perforated sheets is on the rise, driven by architectural innovations and industrial advancements. Authoritative sources such as industry reports from architectural firms and manufacturing associations highlight the growing market and technological advances, making it imperative to choose reputable suppliers with consistent product quality. Building Trust through Transparency Transparent pricing models help build trust with consumers and businesses. Reliable suppliers provide detailed pricing breakdowns, including material costs, labor, and delivery charges. This transparency ensures customers are fully informed about what they are paying for, enhancing trust and establishing long-term business relationships. In conclusion, the perforated sheet market is diverse, with numerous variables impacting the price per kilogram. By considering the material, manufacturing process, and supplier transparency, you can make informed decisions that balance cost and quality. Utilizing the expertise of industry professionals and staying abreast of market trends ensures you capitalize on the best available options for your specific needs. The key to maximizing value lies in thorough research and partnership with credible suppliers committed to providing high-quality perforated sheets.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP