2 月 . 04, 2025 05:37

Back to list

Custom Ring Barbed Wire China Suppliers 730mm Coil Diameter Ribbon Barbed Wire Used for Backyard Security Fence

In the intricate world of manufacturing and design, perforated sheet metal plays a pivotal role that often goes unnoticed. Far beyond its initial perception as a simplistic material, perforated sheet metal finds its application across various industries, ranging from architecture and interior design to automotive and filtration systems. Understanding the nuances of this versatile material can offer engineers and designers innovative solutions to otherwise complex problems.

The choice of material—whether aluminum, stainless steel, or carbon steel—depends significantly on the intended application and environmental considerations. Suppliers with a keen understanding of material science can guide clients in selecting the optimal alloy that balances cost with durability and performance. For example, stainless steel's corrosion resistance is vital for outdoor architectural applications, while aluminum's lightweight nature is ideal for automotive uses. Engagement with a credible supplier provides the advantage of cutting-edge technology and innovative production methods. Modern perforation processes involve advanced CNC machining and laser cutting, ensuring precision and repeatability across even the most intricate designs. These high-precision techniques not only minimize waste but also enhance the overall quality and performance of the end product. Trust in a supplier is built on their track record of delivering consistent quality and adhering to industry certifications. ISO certifications, for example, are indicative of a supplier's commitment to maintaining high-quality standards throughout their operations. Investing time to verify these credentials can safeguard against potential supply chain disruptions that might compromise project timelines. For industries challenged with strict regulatory compliance, an authoritative supplier offers added benefits. They bring in-depth knowledge of compliance requirements specific to various sectors, thereby ensuring that the sheets supplied meet all necessary regulatory standards. This expertise can prevent costly mistakes, such as using materials that fail to meet environmental or safety regulations. In summary, perforated sheet metal is far more than a structural component; it is a cornerstone of innovation across multiple industries. Selecting the right supplier, one that embodies expertise, reliability, and a commitment to quality, ensures the successful integration of perforated sheet metal into any project. Whether it serves an aesthetic, structural, or functional purpose, the future of design and manufacturing could be significantly shaped by this versatile material. Those who capitalize on the benefits of perforated sheet metal today, armed with insights from authoritative suppliers, are likely to lead the charge in tomorrow's industrial advancements.

The choice of material—whether aluminum, stainless steel, or carbon steel—depends significantly on the intended application and environmental considerations. Suppliers with a keen understanding of material science can guide clients in selecting the optimal alloy that balances cost with durability and performance. For example, stainless steel's corrosion resistance is vital for outdoor architectural applications, while aluminum's lightweight nature is ideal for automotive uses. Engagement with a credible supplier provides the advantage of cutting-edge technology and innovative production methods. Modern perforation processes involve advanced CNC machining and laser cutting, ensuring precision and repeatability across even the most intricate designs. These high-precision techniques not only minimize waste but also enhance the overall quality and performance of the end product. Trust in a supplier is built on their track record of delivering consistent quality and adhering to industry certifications. ISO certifications, for example, are indicative of a supplier's commitment to maintaining high-quality standards throughout their operations. Investing time to verify these credentials can safeguard against potential supply chain disruptions that might compromise project timelines. For industries challenged with strict regulatory compliance, an authoritative supplier offers added benefits. They bring in-depth knowledge of compliance requirements specific to various sectors, thereby ensuring that the sheets supplied meet all necessary regulatory standards. This expertise can prevent costly mistakes, such as using materials that fail to meet environmental or safety regulations. In summary, perforated sheet metal is far more than a structural component; it is a cornerstone of innovation across multiple industries. Selecting the right supplier, one that embodies expertise, reliability, and a commitment to quality, ensures the successful integration of perforated sheet metal into any project. Whether it serves an aesthetic, structural, or functional purpose, the future of design and manufacturing could be significantly shaped by this versatile material. Those who capitalize on the benefits of perforated sheet metal today, armed with insights from authoritative suppliers, are likely to lead the charge in tomorrow's industrial advancements.

Next:

Latest news

-

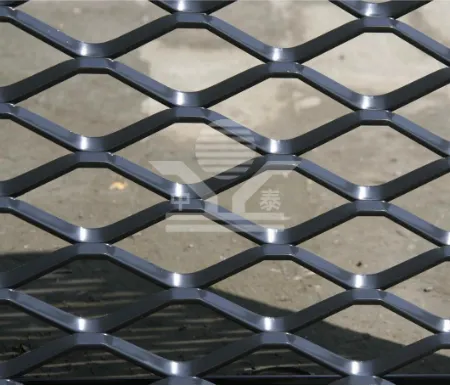

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP