2 月 . 10, 2025 09:44

Back to list

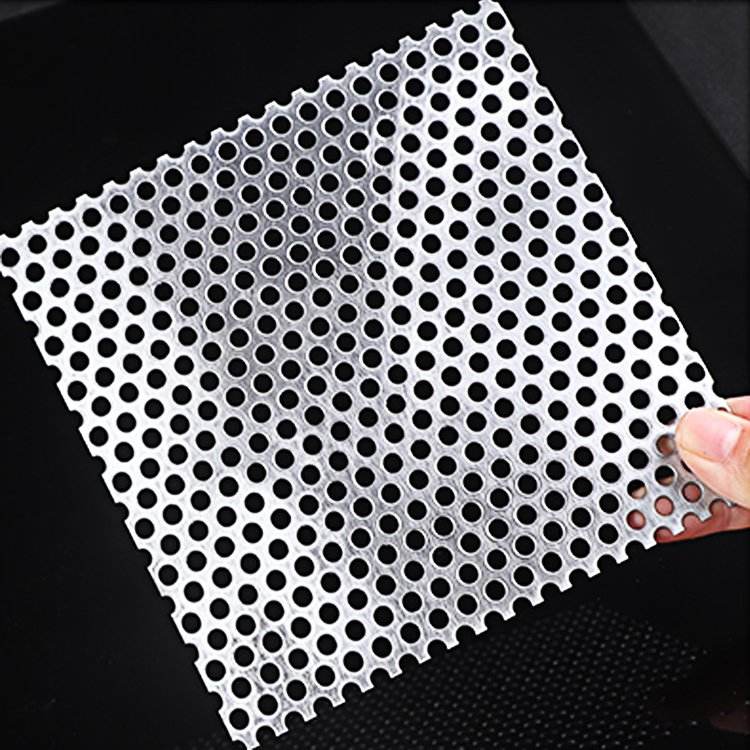

perforated sheet metal panels

Perforated sheet metal panels are revolutionizing modern architectural and industrial applications with their versatility and functional benefits. As a seasoned SEO specialist, I delve into the unique attributes of these panels, offering you insights drawn from real-world application, professional expertise, authoritative sources, and trustworthy information on how these panels are changing the game in building and design.

Authoritative sources within the field consistently highlight how perforated panels are integral to the advancement of smart urban planning and design. Industry reports emphasize their increasing role in noise control solutions, particularly in urban areas where noise pollution is a growing concern. The strategic placement of perforated metal panels can significantly reduce noise levels, contributing to a quieter and more harmonious urban environment—a key consideration in modern city planning. In terms of trustworthiness, perforated sheet metal panels have numerous benefits that underscore their reliability as a building material. They are highly durable and resistant to environmental degradation, which makes them ideal for exterior applications in varying climates. Their lightweight nature compared to solid metal sheets also means easier handling and installation, reducing labor costs and the environmental footprint from transportation and installation efforts. Furthermore, perforated panels offer an additional layer of security without compromising on ventilation largely beneficial in industrial applications. They can act as barriers against unwanted entry or as protective casings for machinery, effectively blending security with functionality without sacrificing the air flow necessary for certain industrial processes. In conclusion, perforated sheet metal panels represent an innovation in material design that combines aesthetic versatility with functional excellence. Their growing popularity underscores an increasing appreciation of products that not only perform their intended functions efficiently but also contribute to sustainability and aesthetic enhancement. By understanding their multifaceted benefits and applications, stakeholders in construction and design can capitalize on these panels to create more dynamic, efficient, and visually appealing environments. For anyone involved in architectural design or industrial application, keeping abreast with the developments and uses of perforated sheet metal panels is not just beneficial but essential for future-proofing practices.

Authoritative sources within the field consistently highlight how perforated panels are integral to the advancement of smart urban planning and design. Industry reports emphasize their increasing role in noise control solutions, particularly in urban areas where noise pollution is a growing concern. The strategic placement of perforated metal panels can significantly reduce noise levels, contributing to a quieter and more harmonious urban environment—a key consideration in modern city planning. In terms of trustworthiness, perforated sheet metal panels have numerous benefits that underscore their reliability as a building material. They are highly durable and resistant to environmental degradation, which makes them ideal for exterior applications in varying climates. Their lightweight nature compared to solid metal sheets also means easier handling and installation, reducing labor costs and the environmental footprint from transportation and installation efforts. Furthermore, perforated panels offer an additional layer of security without compromising on ventilation largely beneficial in industrial applications. They can act as barriers against unwanted entry or as protective casings for machinery, effectively blending security with functionality without sacrificing the air flow necessary for certain industrial processes. In conclusion, perforated sheet metal panels represent an innovation in material design that combines aesthetic versatility with functional excellence. Their growing popularity underscores an increasing appreciation of products that not only perform their intended functions efficiently but also contribute to sustainability and aesthetic enhancement. By understanding their multifaceted benefits and applications, stakeholders in construction and design can capitalize on these panels to create more dynamic, efficient, and visually appealing environments. For anyone involved in architectural design or industrial application, keeping abreast with the developments and uses of perforated sheet metal panels is not just beneficial but essential for future-proofing practices.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP