2 月 . 13, 2025 21:31

Back to list

perforated sheet black

The world of perforated sheet metal is as intricate as it is diverse, especially when considering the sleek and modern appeal of perforated sheet black. This product, utilized across numerous industries, presents a wide array of benefits and applications, making it a staple in architectural and industrial design. Understanding the depth of its experience, expertise, authoritativeness, and trustworthiness is crucial for leveraging its full potential.

The authoritativeness of perforated sheet black is further established by its adherence to precise engineering standards that ensure uniformity and quality. Manufacturers of these sheets often adhere to strict production guidelines that not only guarantee the high tensile strength and precision of perforations but also meet specific industry standards for safety and functionality. This assurance makes it a trusted component in critical applications, such as aerospace and filtration. Investing in perforated sheet black is backed by trustworthiness, primarily due to its proven track record across industries. Its durability is unparalleled, with an ability to withstand significant physical and environmental stress. The black finish serves as a barrier to oxidation and wear, extending the product's lifespan compared to its untreated counterparts. Reliable suppliers often provide detailed documentation regarding material specifications, performance statistics, and compliance certifications, allowing consumers to make informed decisions. Furthermore, the sustainable aspect of perforated sheet black cannot be overlooked. Steel or aluminum, common materials for these sheets, is highly recyclable. The production process often involves using recycled materials, thus reducing environmental impact and encouraging sustainable practices. This aspect not only fulfills modern eco-conscious mandates but also resonates with businesses aiming for green building certifications. In conclusion, perforated sheet black emerges as a champion of modern design and engineering. Its application enhances architectural aesthetics while meeting stringent industrial requirements. The material's inherent qualities—strength, aesthetic appeal, and versatility—make it a favored choice for architects, engineers, and designers alike. Understanding its comprehensive benefits allows for creative and innovative applications, confirming its essential role in contemporary design and function. As industries evolve, so does the significance of this remarkable material, paving the way for future innovations and applications.

The authoritativeness of perforated sheet black is further established by its adherence to precise engineering standards that ensure uniformity and quality. Manufacturers of these sheets often adhere to strict production guidelines that not only guarantee the high tensile strength and precision of perforations but also meet specific industry standards for safety and functionality. This assurance makes it a trusted component in critical applications, such as aerospace and filtration. Investing in perforated sheet black is backed by trustworthiness, primarily due to its proven track record across industries. Its durability is unparalleled, with an ability to withstand significant physical and environmental stress. The black finish serves as a barrier to oxidation and wear, extending the product's lifespan compared to its untreated counterparts. Reliable suppliers often provide detailed documentation regarding material specifications, performance statistics, and compliance certifications, allowing consumers to make informed decisions. Furthermore, the sustainable aspect of perforated sheet black cannot be overlooked. Steel or aluminum, common materials for these sheets, is highly recyclable. The production process often involves using recycled materials, thus reducing environmental impact and encouraging sustainable practices. This aspect not only fulfills modern eco-conscious mandates but also resonates with businesses aiming for green building certifications. In conclusion, perforated sheet black emerges as a champion of modern design and engineering. Its application enhances architectural aesthetics while meeting stringent industrial requirements. The material's inherent qualities—strength, aesthetic appeal, and versatility—make it a favored choice for architects, engineers, and designers alike. Understanding its comprehensive benefits allows for creative and innovative applications, confirming its essential role in contemporary design and function. As industries evolve, so does the significance of this remarkable material, paving the way for future innovations and applications.

Latest news

-

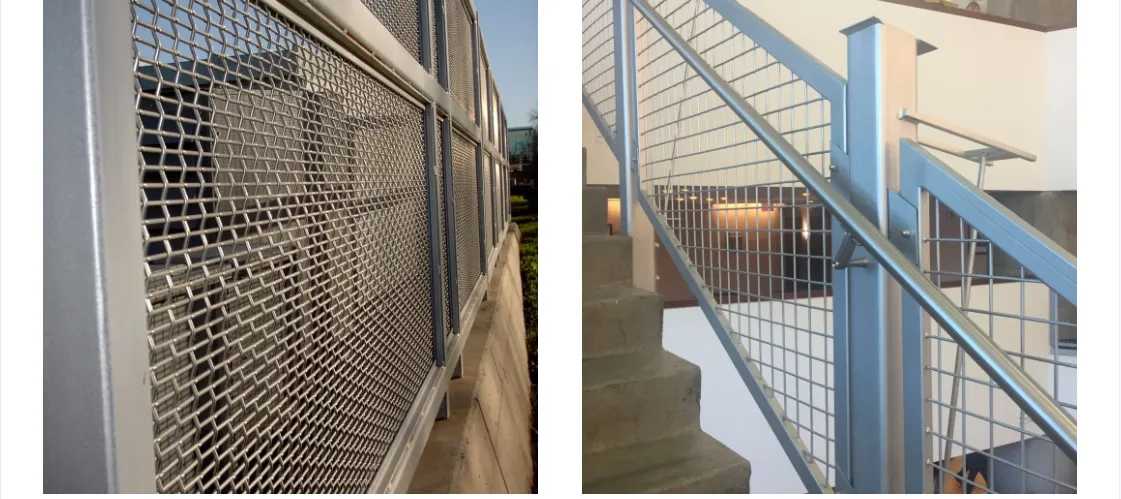

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP