2 月 . 15, 2025 01:58

Back to list

perforated metal sheet hexagon

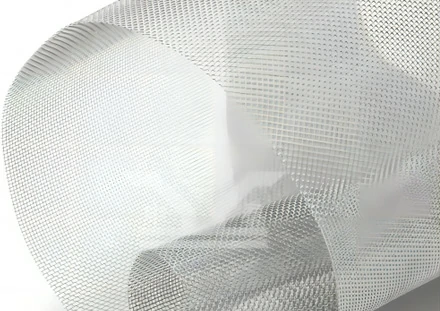

Perforated metal sheets, particularly those with a hexagonal pattern, have surged in popularity across various industries due to their unique combination of functionality and aesthetic appeal. These sheets are not only a testament to engineering innovation but also serve as a versatile solution in architectural and industrial applications.

To ensure maximum performance and safety, it's crucial to source perforated metal sheets from reputable manufacturers. These suppliers should be certified and uphold rigorous quality control measures to guarantee product consistency. Look for manufacturers that offer detailed documentation on material specifications, production processes, and performance metrics. Installation of hexagonal perforated sheets should also be carried out by professionals with experience in handling and installing such materials. Proper installation ensures not only aesthetic coherence but also functional efficiency, preventing issues such as misalignment or structural compromise. Furthermore, maintenance is essential to extend the life span of these sheets. Regular inspections and cleaning prevent debris buildup in the perforations, which can otherwise hamper their effectiveness. Depending on the environmental exposure, some finishes may require periodic re-application to maintain their protective qualities. In conclusion, hexagon-perforated metal sheets are a testament to the convergence of design and utility. Their adaptability and robust design make them an invaluable resource in both architectural and industrial contexts. For businesses and firms looking to integrate these into their projects, focusing on sourcing high-quality materials and professional installation will ensure they leverage the full benefits these sheets have to offer. As industries continue to evolve, the demand for innovative, efficient, and aesthetically pleasing materials like these will only grow, making them a wise investment for the future.

To ensure maximum performance and safety, it's crucial to source perforated metal sheets from reputable manufacturers. These suppliers should be certified and uphold rigorous quality control measures to guarantee product consistency. Look for manufacturers that offer detailed documentation on material specifications, production processes, and performance metrics. Installation of hexagonal perforated sheets should also be carried out by professionals with experience in handling and installing such materials. Proper installation ensures not only aesthetic coherence but also functional efficiency, preventing issues such as misalignment or structural compromise. Furthermore, maintenance is essential to extend the life span of these sheets. Regular inspections and cleaning prevent debris buildup in the perforations, which can otherwise hamper their effectiveness. Depending on the environmental exposure, some finishes may require periodic re-application to maintain their protective qualities. In conclusion, hexagon-perforated metal sheets are a testament to the convergence of design and utility. Their adaptability and robust design make them an invaluable resource in both architectural and industrial contexts. For businesses and firms looking to integrate these into their projects, focusing on sourcing high-quality materials and professional installation will ensure they leverage the full benefits these sheets have to offer. As industries continue to evolve, the demand for innovative, efficient, and aesthetically pleasing materials like these will only grow, making them a wise investment for the future.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP