Understanding Perforated Metal Sheets in CAD Design

Perforated metal sheets have emerged as a vital component in various industries, ranging from architecture to automotive, due to their unique properties and aesthetic appeal. As technology progresses, Computer-Aided Design (CAD) has become an indispensable tool for designing and modeling these intricate sheets. This article explores the significance of perforated metal sheets in CAD drawings, their applications, and the design principles that underpin their creation.

What are Perforated Metal Sheets?

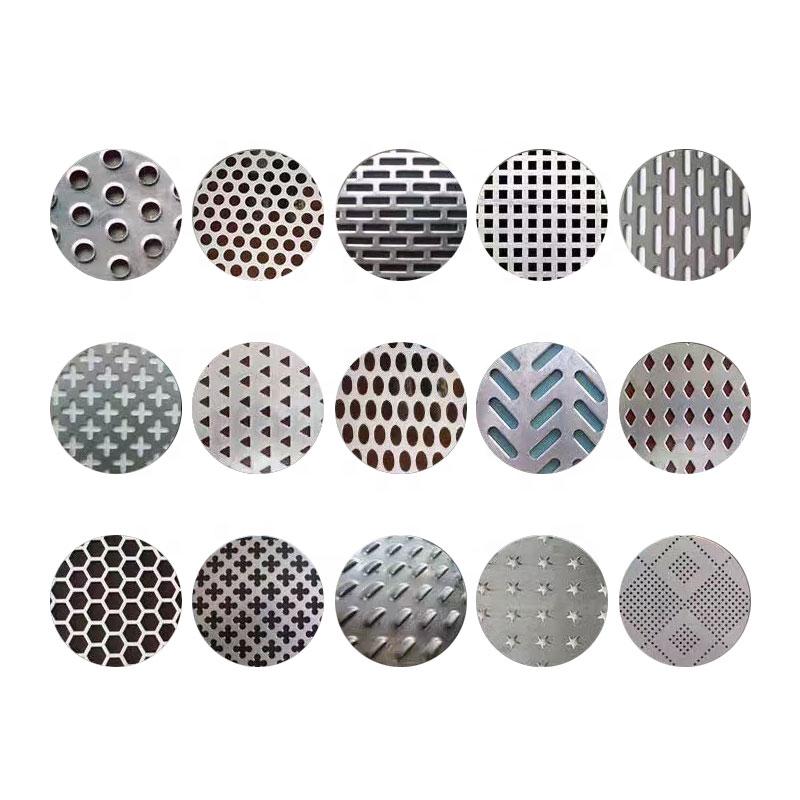

Perforated metal sheets are materials made from a variety of metals, such as steel, aluminum, or stainless steel, that have been punched or stamped with a pattern of holes. These holes can vary in size, shape, and spacing, allowing for a wide range of applications. The resulting product is not only functional but also visually appealing, making it desirable for architectural features, industrial uses, and decorative elements.

The Role of CAD in Designing Perforated Metal Sheets

The advent of CAD software has revolutionized the metal fabrication industry. CAD tools enable designers to create precise 2D and 3D representations of perforated metal sheets, facilitating better visualization and modification during the design process. With CAD, engineers can easily adjust hole dimensions, patterns, and the overall layout of the sheet to meet specific design requirements.

One of the primary benefits of using CAD for perforated metal sheets is the ability to simulate different perforation strategies. Designers can experiment with various hole configurations and their potential impact on weight, strength, airflow, and light transmission. This flexibility is crucial in industries where structural integrity and aesthetics must coexist harmoniously.

Applications of Perforated Metal Sheets

Perforated metal sheets find applications in diverse fields. In architecture, they are used in facades, sunshades, railings, and ceiling systems. The perforations allow for natural ventilation and light filtration, enhancing the building's environmental performance and energy efficiency.

In the automotive industry, perforated sheets are often employed in sound dampening components and grilles, striking a balance between function and design. Additionally, the filtration industry utilizes perforated metal sheets in filter elements, where the size and distribution of holes are critical to the performance of the filtration system.

perforated metal sheet cad drawing

Moreover, in the realm of arts and crafts, designers use perforated sheets to create intricate designs and sculptures, exemplifying how functional materials can also serve as canvases for creativity.

Designing with CAD Key Considerations

When designing perforated metal sheets in CAD, several principles must be considered

1. Material Selection Choosing the right material is paramount. Different metals offer various properties such as strength, corrosion resistance, and weight. CAD allows designers to visualize how different materials will perform with specific perforation patterns.

2. Hole Size and Spacing The size and arrangement of the holes directly affect the sheet's functionality. For instance, a sheet designed for ventilation may require larger holes spaced further apart compared to one intended for filtration, where smaller, closely spaced holes may be necessary.

3. Structural Integrity Designers must ensure that the integrity of the sheet is maintained despite the perforations. CAD simulations can help visualize stress points and ensure that the final product meets structural requirements.

4. Aesthetic Appeal With the rise of modern architectural design, the aesthetic aspect of perforated sheets has gained significant attention. CAD allows for the exploration of various patterns and designs, helping to create visually stunning installations.

5. Manufacturing Constraints Understanding the capabilities and limitations of the manufacturing processes is crucial. CAD helps in designing sheets that are not only functional but also feasible to produce, minimizing waste and ensuring cost-effectiveness.

Conclusion

Perforated metal sheets are a testament to the synergy between functionality and aesthetics, offering versatile solutions across various industries. As designers leverage the capabilities of CAD software, the possibilities for creating innovative perforated designs continue to expand. The combination of precise engineering and creative design ensures that these materials will remain integral to modern applications, meeting the evolving demands of both engineers and architects. Whether for practical applications or artistic endeavors, perforated metal sheets, underpinned by effective CAD drawings, represent a unique blend of art and science in the world of design and manufacturing.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.