2 月 . 15, 2025 02:46

Back to list

perforated metal mesh

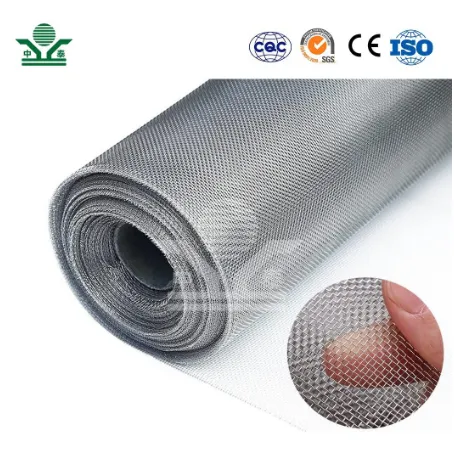

Perforated metal mesh has revolutionized various industries with its versatile applications, demonstrating a blend of practicality and aesthetic appeal. With years of experience in this field, I can provide insights into why this material is gaining traction and how its characteristics align with key industry requirements.

Authoritatively speaking, the sustainability aspect of perforated metal mesh cannot be overstated. Metals used in producing mesh are often recyclable, easing concerns of environmental impact. Furthermore, given its ability to modulate temperatures passively—by allowing air flow and managing sunlight exposure—it contributes to the energy efficiency of buildings. This positions it as a forward-thinking solution in eco-conscious design, an issue of growing importance in global architecture and construction standards. The trustworthiness of perforated metal mesh as a product is evident through the rigorous testing it undergoes to meet safety and durability standards. Its ability to withstand harsh environmental conditions without compromising performance assures stakeholders in its reliability. Certifications from global standards organizations further enhance its credibility as a quality raw material in construction and manufacturing processes. Industry practitioners may find practical experience compelling when considering perforated metal mesh for new projects. Testimonials from engineers and architects highlight its ease of installation and maintenance. Time efficiencies due to its lightweight nature compared to traditional materials can significantly reduce labor costs and project timelines. Incorporating perforated metal mesh is a decision steered not only by creative inspiration but also by sustained performance metrics that ensure projects meet contemporary demands. As industries progress towards more sustainable and innovative practices, materials like perforated metal mesh are at the forefront, demonstrating a commitment to quality and forward-thinking design principles. Such products reflect advancements in material science that empower creators to surpass conventional limits, thus pushing the boundaries of what’s possible in modern design and construction.

Authoritatively speaking, the sustainability aspect of perforated metal mesh cannot be overstated. Metals used in producing mesh are often recyclable, easing concerns of environmental impact. Furthermore, given its ability to modulate temperatures passively—by allowing air flow and managing sunlight exposure—it contributes to the energy efficiency of buildings. This positions it as a forward-thinking solution in eco-conscious design, an issue of growing importance in global architecture and construction standards. The trustworthiness of perforated metal mesh as a product is evident through the rigorous testing it undergoes to meet safety and durability standards. Its ability to withstand harsh environmental conditions without compromising performance assures stakeholders in its reliability. Certifications from global standards organizations further enhance its credibility as a quality raw material in construction and manufacturing processes. Industry practitioners may find practical experience compelling when considering perforated metal mesh for new projects. Testimonials from engineers and architects highlight its ease of installation and maintenance. Time efficiencies due to its lightweight nature compared to traditional materials can significantly reduce labor costs and project timelines. Incorporating perforated metal mesh is a decision steered not only by creative inspiration but also by sustained performance metrics that ensure projects meet contemporary demands. As industries progress towards more sustainable and innovative practices, materials like perforated metal mesh are at the forefront, demonstrating a commitment to quality and forward-thinking design principles. Such products reflect advancements in material science that empower creators to surpass conventional limits, thus pushing the boundaries of what’s possible in modern design and construction.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP