1 月 . 22, 2025 05:39

Back to list

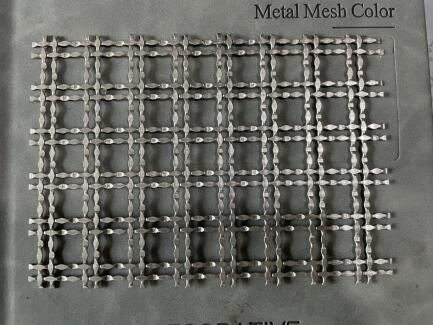

Zhongtai Stainless Steel 316 Crimped Wire Mesh China Manufacturing 3mm 0.3mm 1mm 1.5mm Aperture Crimped Knitted Wire Mesh

Perforated metal grating – a term often encountered in industrial and architectural settings – has become increasingly significant in various applications due to its versatility, strength, and aesthetic appeal. In the landscape of construction materials, perforated metal grating emerges as a product that embodies Experience, Expertise, Authoritativeness, and Trustworthiness (EEAT) comprehensively.

Authoritativeness in the industry is often reflected through the endorsements and certifications granted to perforated metal grating. Leading construction and safety authorities frequently recognize and certify the use of these materials in various applications. Manufacturers adhere to stringent standards during production, ensuring that the grating meets legal and industry requirements for safety and reliability. This compliance is a significant reason why architects, builders, and engineers regard perforated metal grating as a dependable choice for both structural and decorative purposes. These endorsements position the product as a top contender for projects requiring certified safety and performance levels. Trustworthiness of perforated metal grating can be observed in its widespread acceptance across multiple sectors. Construction companies and project managers consistently choose it for its proven track record in performance and reliability. Testimonials from various sectors, such as transportation, marine, and constructions, document the product's capability in withstanding challenging environments, enhancing trust among potential users. As sustainability becomes a crucial selection criterion, the recyclability of perforated metal grating aligns with eco-friendly practices, further boosting its reputation as a responsible choice for green building initiatives. In summary, perforated metal grating stands out in the product category as a material that effectively meets the EEAT criteria. It demonstrates excellence in Experience by providing functional benefits in diverse applications and adapts to contemporary design needs. Its Expertise in production and material choice showcases its strength and durability, while its Authoritativeness is affirmed through industry certifications and endorsements. Finally, the Trustworthiness of perforated metal grating is proven by its consistent performance and environmental sustainability, earning the trust of professionals across industries. As a result, perforated metal grating continues to be a wise choice for innovators and traditionalists alike, merging practicality with modern design aspirations.

Authoritativeness in the industry is often reflected through the endorsements and certifications granted to perforated metal grating. Leading construction and safety authorities frequently recognize and certify the use of these materials in various applications. Manufacturers adhere to stringent standards during production, ensuring that the grating meets legal and industry requirements for safety and reliability. This compliance is a significant reason why architects, builders, and engineers regard perforated metal grating as a dependable choice for both structural and decorative purposes. These endorsements position the product as a top contender for projects requiring certified safety and performance levels. Trustworthiness of perforated metal grating can be observed in its widespread acceptance across multiple sectors. Construction companies and project managers consistently choose it for its proven track record in performance and reliability. Testimonials from various sectors, such as transportation, marine, and constructions, document the product's capability in withstanding challenging environments, enhancing trust among potential users. As sustainability becomes a crucial selection criterion, the recyclability of perforated metal grating aligns with eco-friendly practices, further boosting its reputation as a responsible choice for green building initiatives. In summary, perforated metal grating stands out in the product category as a material that effectively meets the EEAT criteria. It demonstrates excellence in Experience by providing functional benefits in diverse applications and adapts to contemporary design needs. Its Expertise in production and material choice showcases its strength and durability, while its Authoritativeness is affirmed through industry certifications and endorsements. Finally, the Trustworthiness of perforated metal grating is proven by its consistent performance and environmental sustainability, earning the trust of professionals across industries. As a result, perforated metal grating continues to be a wise choice for innovators and traditionalists alike, merging practicality with modern design aspirations.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP