2 月 . 05, 2025 03:22

Back to list

perforated mesh suppliers

In the dynamic world of architectural design and industrial applications, perforated mesh has carved out a significant niche due to its versatility, durability, and aesthetic potential. For those seeking top-notch perforated mesh suppliers, understanding the nuances of supplier selection is crucial. This article explores essential aspects of choosing reliable suppliers, drawing on real-world experience and expertise to ensure you make the most informed decision.

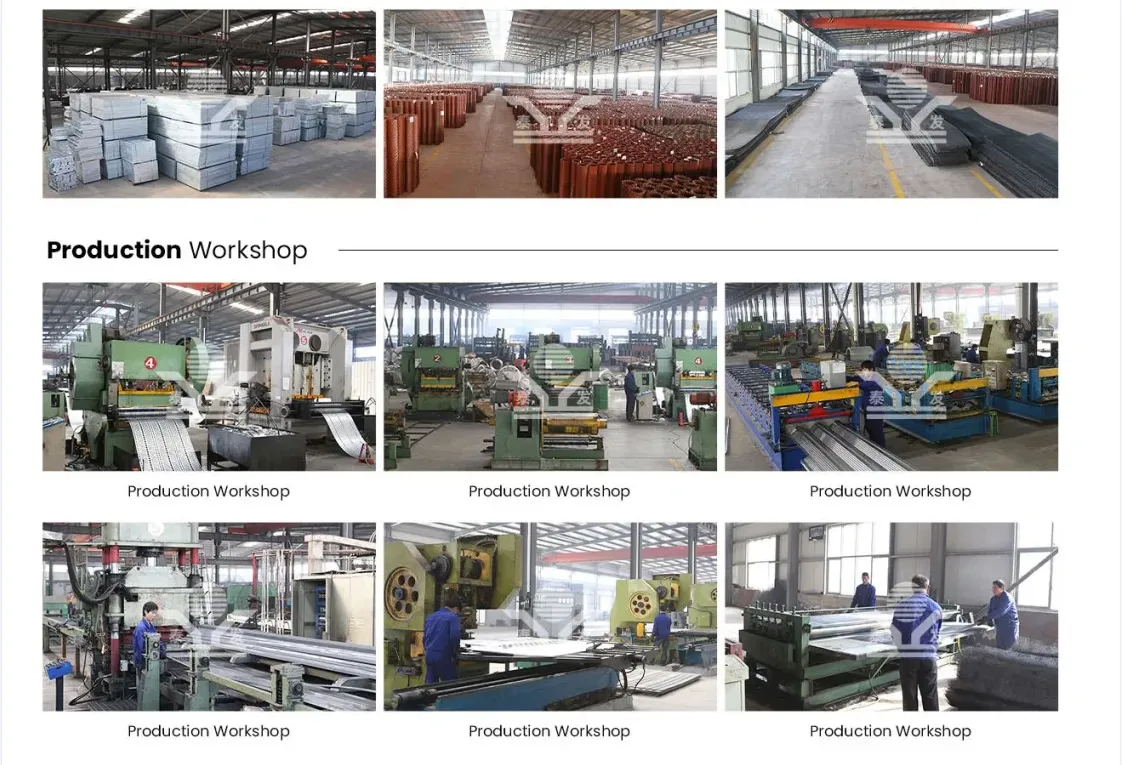

Experience with multiple perforated mesh projects provides valuable insights into the strengths and weaknesses of different suppliers. For instance, a supplier with a robust portfolio in architectural applications may excel at delivering aesthetically pleasing designs, while those with strengths in industrial applications might offer superior products for durability and performance under harsh conditions. Case studies and testimonials can provide evidence of a supplier's ability to deliver on promises, offering peace of mind to prospective clients. A comprehensive analysis of a supplier’s product range is essential to ensure they can meet diverse project needs. Top suppliers offer a wide variety of patterns, materials, and finishes, ensuring the flexibility to meet any design or functional requirement. From stainless steel to aluminum and beyond, the material choice can significantly impact both the performance and visual appeal of the finished product. The ability to customize these attributes is a hallmark of a versatile supplier, demonstrating their commitment to meeting unique customer needs. The technological capabilities of a supplier can also play a significant role in their selection. Suppliers that invest in state-of-the-art manufacturing equipment are often able to produce higher quality products at competitive prices. Advanced technology allows for precision in perforation patterns, ensuring that each piece of mesh is manufactured to the exact specifications required by the project. Finally, assessing the financial stability of potential suppliers can provide insight into their long-term viability and capacity to support large projects. A financially stable supplier is less likely to experience disruptions in production and can typically manage supply chain issues more effectively, thereby ensuring timely delivery of products. In conclusion, selecting the right perforated mesh supplier involves a careful evaluation of their expertise, authoritativeness, trustworthiness, and experience. By considering these factors and reviewing detailed aspects such as product range, technological capability, and financial stability, decision-makers can identify suppliers that will not only provide high-quality products but also contribute positively to the success of their projects. This informed approach ensures that the selected supplier can meet or exceed expectations, allowing the unique properties of perforated mesh to shine in any application.

Experience with multiple perforated mesh projects provides valuable insights into the strengths and weaknesses of different suppliers. For instance, a supplier with a robust portfolio in architectural applications may excel at delivering aesthetically pleasing designs, while those with strengths in industrial applications might offer superior products for durability and performance under harsh conditions. Case studies and testimonials can provide evidence of a supplier's ability to deliver on promises, offering peace of mind to prospective clients. A comprehensive analysis of a supplier’s product range is essential to ensure they can meet diverse project needs. Top suppliers offer a wide variety of patterns, materials, and finishes, ensuring the flexibility to meet any design or functional requirement. From stainless steel to aluminum and beyond, the material choice can significantly impact both the performance and visual appeal of the finished product. The ability to customize these attributes is a hallmark of a versatile supplier, demonstrating their commitment to meeting unique customer needs. The technological capabilities of a supplier can also play a significant role in their selection. Suppliers that invest in state-of-the-art manufacturing equipment are often able to produce higher quality products at competitive prices. Advanced technology allows for precision in perforation patterns, ensuring that each piece of mesh is manufactured to the exact specifications required by the project. Finally, assessing the financial stability of potential suppliers can provide insight into their long-term viability and capacity to support large projects. A financially stable supplier is less likely to experience disruptions in production and can typically manage supply chain issues more effectively, thereby ensuring timely delivery of products. In conclusion, selecting the right perforated mesh supplier involves a careful evaluation of their expertise, authoritativeness, trustworthiness, and experience. By considering these factors and reviewing detailed aspects such as product range, technological capability, and financial stability, decision-makers can identify suppliers that will not only provide high-quality products but also contribute positively to the success of their projects. This informed approach ensures that the selected supplier can meet or exceed expectations, allowing the unique properties of perforated mesh to shine in any application.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP