2 月 . 06, 2025 03:35

Back to list

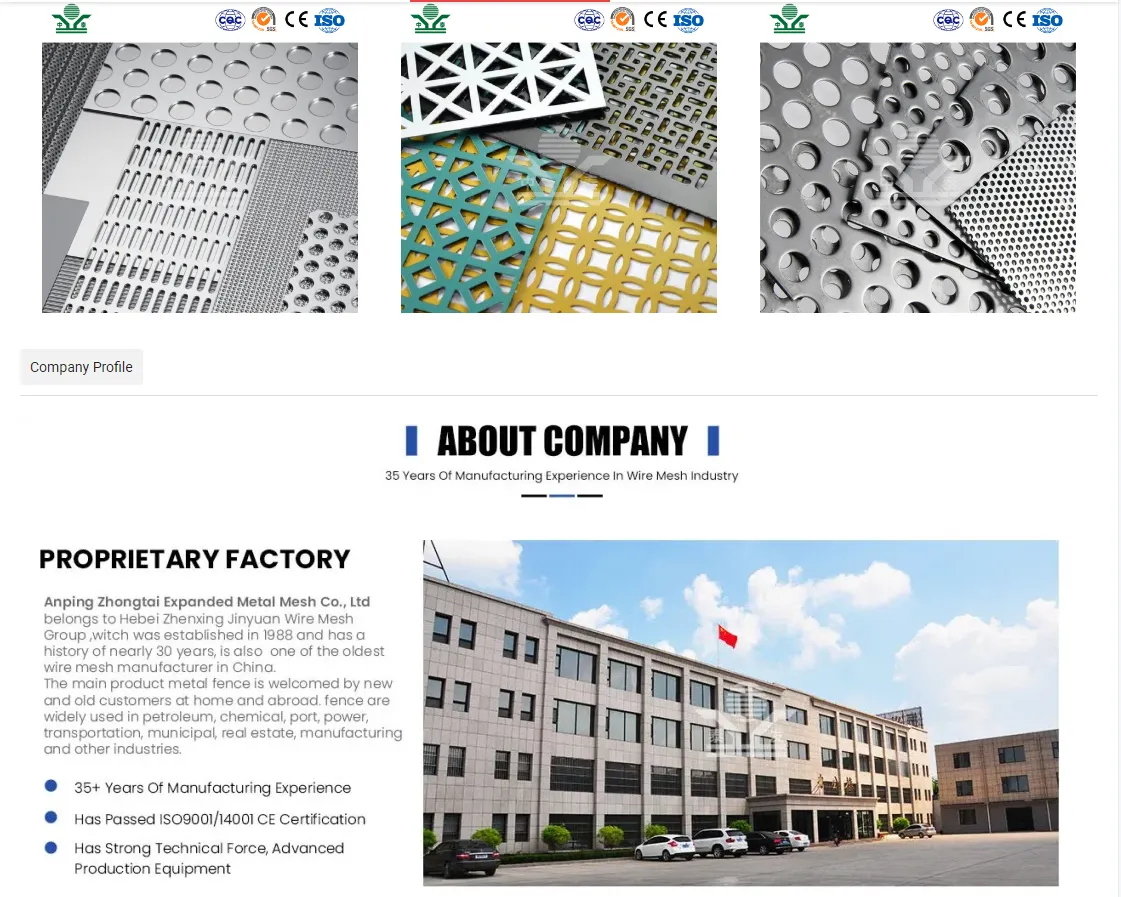

perforated mesh sheet

Perforated mesh sheets, a versatile solution across numerous industries, offer an exceptional blend of functionality and aesthetic appeal. These sheets, engineered with precision, provide both design elegance and operational efficiency, making them a preferred choice in a variety of applications. Let’s delve into the reasons behind their increasing popularity and the expertise required to maximize their utility.

Authoritative voices in the industry emphasize the significance of customization in perforated mesh sheets. Industry leaders provide services that tailor perforation patterns, hole sizes, and sheet dimensions, allowing clients to influence light passage, visibility, and airflow exactly to their specifications. This customization elevates the perforated sheets from a mere structural component to a bespoke solution that can define architectural and industrial projects. Trustworthiness in sourcing perforated mesh sheets is reinforced by compliance with industry standards and rigorous quality checks. Reputable manufacturers engage in ethical sourcing of high-quality materials and certify their products through extensive testing, ensuring durability and performance. Trust is further built through transparent operations, and a robust customer service framework that provides post-purchase support and advisory, helping clients make informed decisions tailored to their applications. In practical application, professionals share numerous success stories of employing perforated mesh sheets effectively in innovative projects. In urban landscaping, for example, these sheets serve as sound barriers along highways, reducing noise pollution while blending seamlessly into the environment with their customizable designs. Similarly, in the realm of modern architecture, perforated sheets are used to create facades that not only provide aesthetic appeal but also improve energy efficiency through strategic sunlight filtration. Ultimately, perforated mesh sheets represent a convergence of experience, expertise, authority, and trustworthiness. Their application goes beyond mere function, serving as an integral component of design innovation and operational excellence. For any road to success in high-quality construction or manufacturing projects, integrating the use of perforated mesh sheets is a step toward achieving optimal results. As industries continue to evolve, the multi-functional nature of perforated mesh sheets ensures that they remain a cornerstone of modern engineering and design solutions.

Authoritative voices in the industry emphasize the significance of customization in perforated mesh sheets. Industry leaders provide services that tailor perforation patterns, hole sizes, and sheet dimensions, allowing clients to influence light passage, visibility, and airflow exactly to their specifications. This customization elevates the perforated sheets from a mere structural component to a bespoke solution that can define architectural and industrial projects. Trustworthiness in sourcing perforated mesh sheets is reinforced by compliance with industry standards and rigorous quality checks. Reputable manufacturers engage in ethical sourcing of high-quality materials and certify their products through extensive testing, ensuring durability and performance. Trust is further built through transparent operations, and a robust customer service framework that provides post-purchase support and advisory, helping clients make informed decisions tailored to their applications. In practical application, professionals share numerous success stories of employing perforated mesh sheets effectively in innovative projects. In urban landscaping, for example, these sheets serve as sound barriers along highways, reducing noise pollution while blending seamlessly into the environment with their customizable designs. Similarly, in the realm of modern architecture, perforated sheets are used to create facades that not only provide aesthetic appeal but also improve energy efficiency through strategic sunlight filtration. Ultimately, perforated mesh sheets represent a convergence of experience, expertise, authority, and trustworthiness. Their application goes beyond mere function, serving as an integral component of design innovation and operational excellence. For any road to success in high-quality construction or manufacturing projects, integrating the use of perforated mesh sheets is a step toward achieving optimal results. As industries continue to evolve, the multi-functional nature of perforated mesh sheets ensures that they remain a cornerstone of modern engineering and design solutions.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP