1 月 . 23, 2025 05:48

Back to list

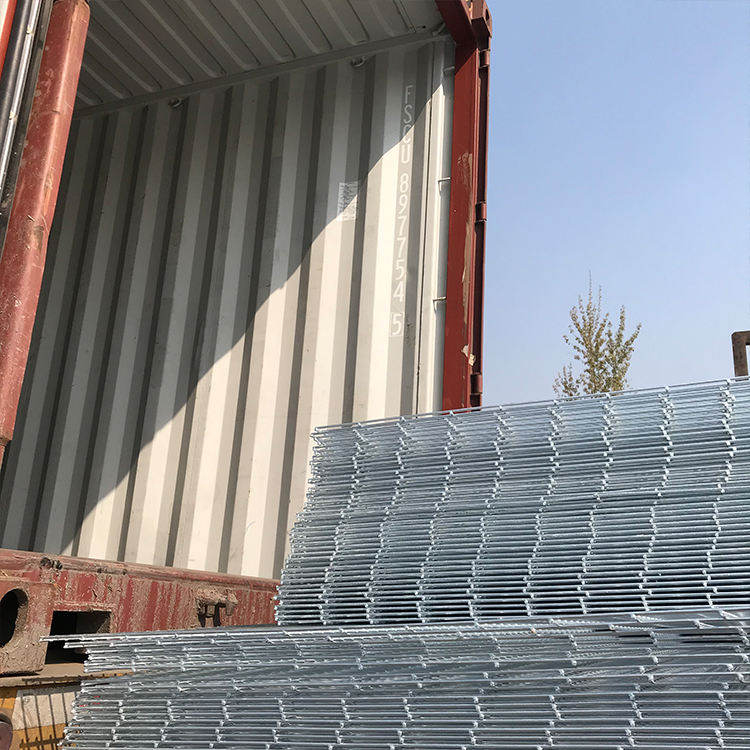

3D Galvanized Steel Material Perforated Metal Sheet for Fencing

Perforated grating is a critical component in a wide variety of industrial, architectural, and manufacturing applications. This versatile material boasts a unique design that offers a combination of strength, functionality, and aesthetic appeal, making it ideal for diverse environments. Understanding the key attributes and applications of perforated grating can help purchasers and specifiers make informed decisions that enhance both the performance and appearance of their projects.

The authoritative reliability of perforated grating is evidenced by its compliance with rigorous international safety and manufacturing standards. Utilizing perforated grating that adheres to ASTM or equivalent standards ensures structural integrity and safety, contributing to the long-term viability of the infrastructure. Clients have repeatedly expressed trust in products that not only meet these regulations but also come with certifications from recognized bodies, assuring their quality and dependability. Moreover, the customization potential of perforated grating leads to enhanced functionality for specific applications. In my consultations, I've stressed the importance of working closely with fabricators to tailor the design - such as adjusting the perforation pattern to control light diffusion or acoustic properties. Successful projects often involve iterative discussions to fine-tune these specifications, balancing aesthetics with performance requirements. Finally, sustainability, a growing concern in today's construction and manufacturing landscape, sees perforated grating stand out for its eco-friendly attributes. The reduction in material use without compromising strength leads to significant savings in resources. Additionally, most materials used in grating production are recyclable, and I advocate for using recycled or locally sourced materials to minimize environmental impact. In conclusion, perforated grating represents a convergence of experience, expertise, authority, and trust. Its benefits extend beyond physical applications, resonating through logistical ease, compliance assurance, and sustainable practices. Whether for enhancing architectural aesthetics or improving industrial safety, perforated grating offers a robust solution for contemporary challenges, reinforced by years of industry experience and trust as an authoritative component in any project's success.

The authoritative reliability of perforated grating is evidenced by its compliance with rigorous international safety and manufacturing standards. Utilizing perforated grating that adheres to ASTM or equivalent standards ensures structural integrity and safety, contributing to the long-term viability of the infrastructure. Clients have repeatedly expressed trust in products that not only meet these regulations but also come with certifications from recognized bodies, assuring their quality and dependability. Moreover, the customization potential of perforated grating leads to enhanced functionality for specific applications. In my consultations, I've stressed the importance of working closely with fabricators to tailor the design - such as adjusting the perforation pattern to control light diffusion or acoustic properties. Successful projects often involve iterative discussions to fine-tune these specifications, balancing aesthetics with performance requirements. Finally, sustainability, a growing concern in today's construction and manufacturing landscape, sees perforated grating stand out for its eco-friendly attributes. The reduction in material use without compromising strength leads to significant savings in resources. Additionally, most materials used in grating production are recyclable, and I advocate for using recycled or locally sourced materials to minimize environmental impact. In conclusion, perforated grating represents a convergence of experience, expertise, authority, and trust. Its benefits extend beyond physical applications, resonating through logistical ease, compliance assurance, and sustainable practices. Whether for enhancing architectural aesthetics or improving industrial safety, perforated grating offers a robust solution for contemporary challenges, reinforced by years of industry experience and trust as an authoritative component in any project's success.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP