2 月 . 12, 2025 17:23

Back to list

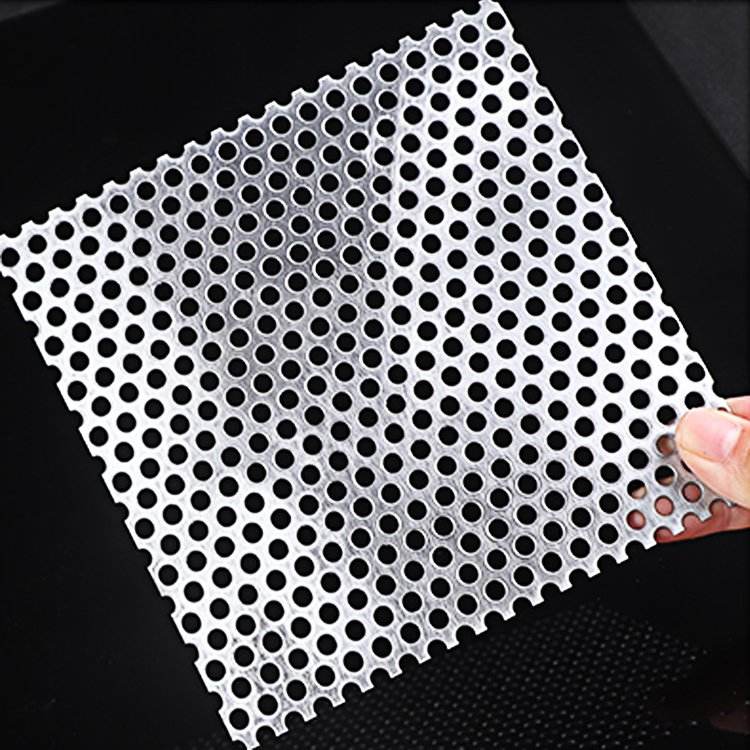

perforated copper plate

Perforated copper plates have emerged as a pivotal component in a multitude of industries, offering unparalleled versatility and reliability. Rooted in centuries of metallurgical innovation, copper has transcended its historical use, now playing a crucial role in modern engineering and design projects. This essay delves deep into the myriad uses, benefits, and material science of perforated copper plates, underscoring their relevance in today's technology-driven landscape.

Artisans and designers have also embraced the creative potential of perforated copper plates. Their unique aesthetic, coupled with the metal's traditional warmth, offers artists the ability to craft striking installations and sculptures. By manipulating perforation patterns, artists can control transparency, play with light and shadows, and create dynamic pieces that interact with the surrounding environment. The authority of perforated copper plates in various sectors is not only grounded in their physical and chemical properties but also in the sustainability profile of copper itself. Copper is 100% recyclable without any loss of performance or quality. This attribute places perforated copper plates at the forefront of environmentally-conscious material choices, appealing to industries and stakeholders committed to reducing their ecological footprint. To truly harness the full potential of perforated copper plates, expertise in material science, engineering, and design is essential. Professionals experienced in metallurgy and design can optimize perforation patterns to meet specific functional and aesthetic requirements. This expert knowledge ensures that the full advantages of copper's unique properties are realized while enhancing the operational effectiveness of the applications where it is used. Trustworthiness and reliability in sourcing perforated copper plates must also be considered. Partnering with reputable manufacturers ensures consistency in quality and adherence to industry standards. By opting for suppliers with a proven track record, businesses not only secure high-quality materials but also forge relationships that assure long-term value and support. In conclusion, perforated copper plates are a testament to the harmonious blend of tradition and innovation. Their multifaceted applications across diverse industries underline their status as an indispensable material of the modern age. Whether in architectural marvels, electronic advancement, industrial machinery, or artistic pursuits, these plates resonate with professionals who value performance, sustainability, and aesthetic brilliance. For businesses and creators alike, investing in perforated copper plates is a commitment to excellence and forward-thinking design.

Artisans and designers have also embraced the creative potential of perforated copper plates. Their unique aesthetic, coupled with the metal's traditional warmth, offers artists the ability to craft striking installations and sculptures. By manipulating perforation patterns, artists can control transparency, play with light and shadows, and create dynamic pieces that interact with the surrounding environment. The authority of perforated copper plates in various sectors is not only grounded in their physical and chemical properties but also in the sustainability profile of copper itself. Copper is 100% recyclable without any loss of performance or quality. This attribute places perforated copper plates at the forefront of environmentally-conscious material choices, appealing to industries and stakeholders committed to reducing their ecological footprint. To truly harness the full potential of perforated copper plates, expertise in material science, engineering, and design is essential. Professionals experienced in metallurgy and design can optimize perforation patterns to meet specific functional and aesthetic requirements. This expert knowledge ensures that the full advantages of copper's unique properties are realized while enhancing the operational effectiveness of the applications where it is used. Trustworthiness and reliability in sourcing perforated copper plates must also be considered. Partnering with reputable manufacturers ensures consistency in quality and adherence to industry standards. By opting for suppliers with a proven track record, businesses not only secure high-quality materials but also forge relationships that assure long-term value and support. In conclusion, perforated copper plates are a testament to the harmonious blend of tradition and innovation. Their multifaceted applications across diverse industries underline their status as an indispensable material of the modern age. Whether in architectural marvels, electronic advancement, industrial machinery, or artistic pursuits, these plates resonate with professionals who value performance, sustainability, and aesthetic brilliance. For businesses and creators alike, investing in perforated copper plates is a commitment to excellence and forward-thinking design.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP