The Versatility of Perforated Aluminum Strips

Perforated aluminum strips have gained popularity in various industries due to their unique properties and versatile applications. These strips are created by punching a series of holes into aluminum sheets, resulting in a lightweight yet durable material that offers numerous benefits.

One of the key advantages of perforated aluminum strips is their strength-to-weight ratio. Aluminum is inherently a strong material, and when it is perforated, it retains its structural integrity while reducing its overall weight. This makes it an ideal choice for applications in the aerospace, automotive, and construction industries, where reducing weight is a critical factor without compromising strength.

Another significant benefit of perforated aluminum strips is their aesthetic appeal. The uniform holes can be designed in various patterns and sizes, allowing for creative expression in architectural applications. Designers often incorporate these strips into building facades, allowing for unique light and shadow effects that enhance the overall appearance of a structure. Moreover, they can also serve practical purposes, such as ventilation or sound attenuation, making them functional as well as visually attractive.

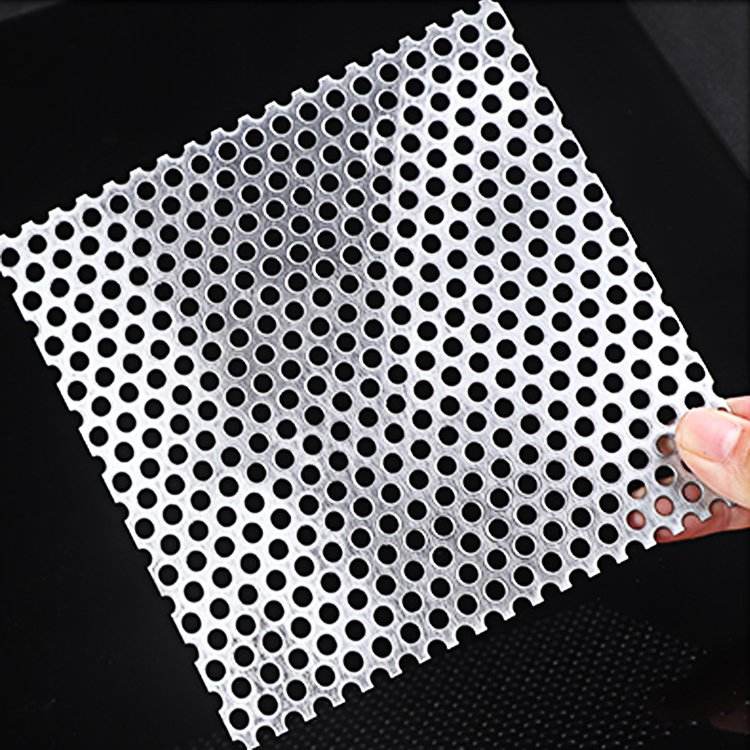

perforated aluminum strip

In addition to aesthetics, perforated aluminum strips offer excellent corrosion resistance. Aluminum naturally forms a protective oxide layer that shields it from environmental factors, prolonging its lifespan even in harsh conditions. This property makes them suitable for outdoor applications, such as fencing, railings, and outdoor furniture. Their durability ensures that they can withstand the elements while maintaining their appearance and function over time.

One of the most common uses of perforated aluminum strips is in the manufacturing of filters and screens. The holes can be precisely engineered to allow specific airflow or liquid passage while blocking unwanted particles or light. This makes them invaluable in applications ranging from industrial filtration systems to architectural screens that provide privacy without sacrificing illumination.

Furthermore, the ease of fabrication associated with perforated aluminum strips enhances their attractiveness for manufacturers. These strips can be cut, bent, and shaped into various forms, making them adaptable for numerous uses. Whether creating custom products or integrating them into larger assemblies, the flexibility of perforated aluminum enables innovation across numerous sectors.

In conclusion, perforated aluminum strips are a remarkable material that combines functionality with aesthetic versatility. Their strength, durability, and adaptability make them suitable for a wide range of applications, from construction to industrial processes. As industries continue to seek lightweight and durable materials, the popularity of perforated aluminum strips is expected to grow, paving the way for even more innovative uses in the future.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.