2 月 . 12, 2025 20:23

Back to list

perforated aluminum strip

Perforated aluminum strips are emerging as a revolutionary material in various industries, offering a unique blend of durability, aesthetic appeal, and functionality. With their multifaceted applications, these strips are proving to be indispensable in sectors ranging from construction to automotive. A keen understanding of their advantages and uses can significantly enhance one’s expertise in material selection and application.

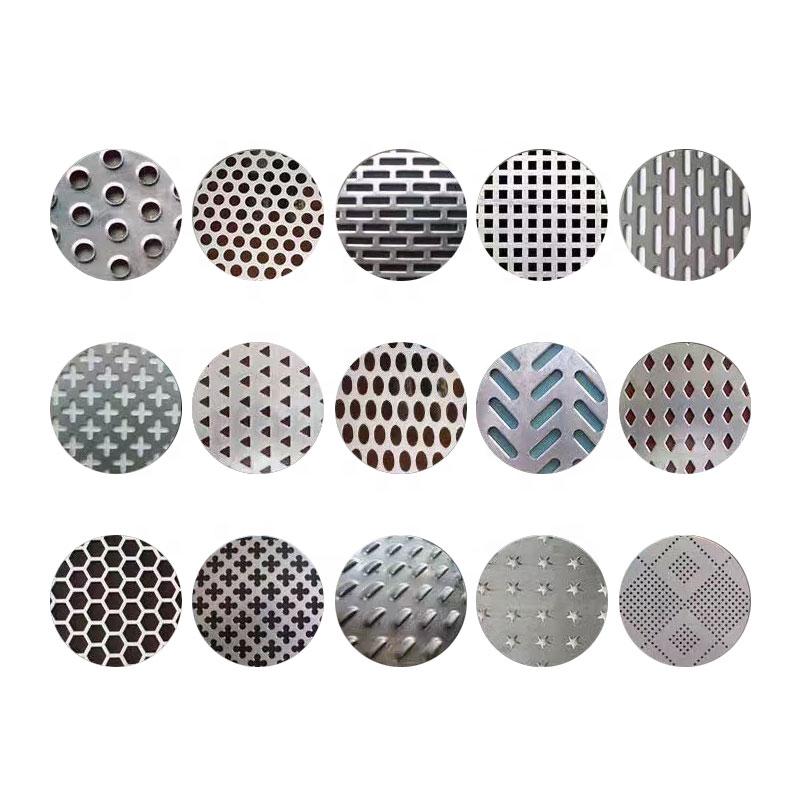

Despite their numerous benefits, perforated aluminum strips also pose certain challenges that experts must navigate. The manufacturing process demands precision and technical know-how to ensure consistent quality and minimize waste. Moreover, selecting the appropriate pattern and hole size is crucial in optimizing the material's performance for specific applications. Therefore, collaboration with experienced engineers and architects becomes essential to harness the full potential of these strips. In terms of cost-effectiveness, perforated aluminum strips demonstrate a favorable return on investment. Their durability and minimal maintenance requirements translate into long-term savings, especially when compared to other materials that may require frequent repairs or replacements. Moreover, the adaptability of these strips allows for seamless integration into existing systems, further enhancing their value proposition for businesses. Safety is another critical consideration where perforated aluminum strips excel. The material is non-combustible, making it an excellent choice for applications where fire resistance is paramount. This safety aspect, combined with its strength and durability, makes the strips suitable for rigorous environments, including industrial facilities and public spaces. As demand for sustainable and efficient materials continues to grow, the relevance of perforated aluminum strips in modern infrastructure is set to increase. Their unique combination of aesthetic appeal, functionality, and environmental benefits positions them as a top choice for designers, engineers, and manufacturers aiming to elevate their projects. In conclusion, perforated aluminum strips offer a compelling solution for various industrial and architectural applications. Their ability to balance performance with aesthetics, along with a commitment to sustainability, makes them a valuable asset in advancing modern design and manufacturing methodologies. As knowledge around these versatile strips expands, they will undoubtedly continue to play a pivotal role in addressing the evolving needs of industries worldwide.

Despite their numerous benefits, perforated aluminum strips also pose certain challenges that experts must navigate. The manufacturing process demands precision and technical know-how to ensure consistent quality and minimize waste. Moreover, selecting the appropriate pattern and hole size is crucial in optimizing the material's performance for specific applications. Therefore, collaboration with experienced engineers and architects becomes essential to harness the full potential of these strips. In terms of cost-effectiveness, perforated aluminum strips demonstrate a favorable return on investment. Their durability and minimal maintenance requirements translate into long-term savings, especially when compared to other materials that may require frequent repairs or replacements. Moreover, the adaptability of these strips allows for seamless integration into existing systems, further enhancing their value proposition for businesses. Safety is another critical consideration where perforated aluminum strips excel. The material is non-combustible, making it an excellent choice for applications where fire resistance is paramount. This safety aspect, combined with its strength and durability, makes the strips suitable for rigorous environments, including industrial facilities and public spaces. As demand for sustainable and efficient materials continues to grow, the relevance of perforated aluminum strips in modern infrastructure is set to increase. Their unique combination of aesthetic appeal, functionality, and environmental benefits positions them as a top choice for designers, engineers, and manufacturers aiming to elevate their projects. In conclusion, perforated aluminum strips offer a compelling solution for various industrial and architectural applications. Their ability to balance performance with aesthetics, along with a commitment to sustainability, makes them a valuable asset in advancing modern design and manufacturing methodologies. As knowledge around these versatile strips expands, they will undoubtedly continue to play a pivotal role in addressing the evolving needs of industries worldwide.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP