2 月 . 13, 2025 15:43

Back to list

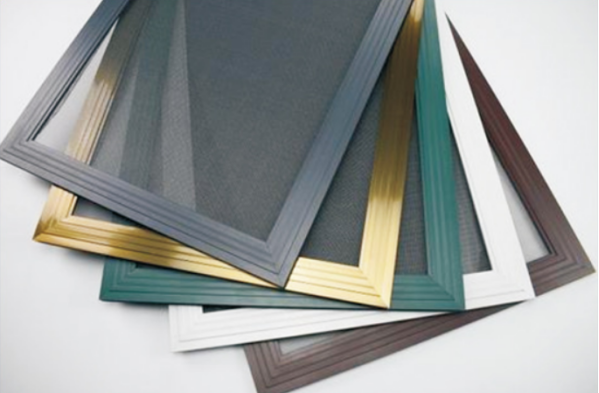

perforated aluminum sheet price

Understanding the cost dynamics of perforated aluminum sheets provides valuable insights for both industrial buyers and DIY enthusiasts. These lightweight, durable materials are indispensable across various applications, making them a staple in construction, architecture, and interior design. Here, we delve into the factors that influence the pricing of perforated aluminum sheets, offering comprehensive expertise from industry insiders to demystify the pricing structure.

Shipping and logistics are other considerations that can impact the final price of perforated aluminum sheets. Transportation fees vary based on distance, weight, and delivery speed. Partnering with local suppliers can reduce shipping costs significantly and provide added benefits such as faster delivery times and ease of potential returns or exchanges. Companies with robust logistics networks might offer better shipping terms, adding value to the purchase. Market demand also exerts influence on prices. During periods of high construction activity, demand for materials like perforated aluminum sheets may surge, consequently increasing prices. Conversely, in slow market conditions, suppliers might offer competitive pricing to move inventory. Monitoring industry trends through regular market analysis can provide advantageous timing for purchases, aligning with periods when prices are more favorable due to market cycles. For consumers seeking perforated aluminum sheets for smaller projects, tapping into the expertise of retailers and suppliers can enhance purchasing decisions. Reputable suppliers offer invaluable insights into the best materials and specifications suitable for specific applications. Recommendations based on experience and expertise help ensure the right balance of quality, cost, and performance, reinforcing trustworthiness in the supply relationship. In conclusion, navigating the pricing landscape of perforated aluminum sheets requires a multifaceted approach that considers raw material costs, manufacturing techniques, customization needs, purchase volume, and logistical concerns. Staying informed about market trends and building relationships with reliable suppliers are essential strategies for securing the best possible pricing. By leveraging expert knowledge and authoritative resources, buyers can make informed decisions that ensure the successful integration of perforated aluminum sheets into their projects, achieving both economic and functional goals.

Shipping and logistics are other considerations that can impact the final price of perforated aluminum sheets. Transportation fees vary based on distance, weight, and delivery speed. Partnering with local suppliers can reduce shipping costs significantly and provide added benefits such as faster delivery times and ease of potential returns or exchanges. Companies with robust logistics networks might offer better shipping terms, adding value to the purchase. Market demand also exerts influence on prices. During periods of high construction activity, demand for materials like perforated aluminum sheets may surge, consequently increasing prices. Conversely, in slow market conditions, suppliers might offer competitive pricing to move inventory. Monitoring industry trends through regular market analysis can provide advantageous timing for purchases, aligning with periods when prices are more favorable due to market cycles. For consumers seeking perforated aluminum sheets for smaller projects, tapping into the expertise of retailers and suppliers can enhance purchasing decisions. Reputable suppliers offer invaluable insights into the best materials and specifications suitable for specific applications. Recommendations based on experience and expertise help ensure the right balance of quality, cost, and performance, reinforcing trustworthiness in the supply relationship. In conclusion, navigating the pricing landscape of perforated aluminum sheets requires a multifaceted approach that considers raw material costs, manufacturing techniques, customization needs, purchase volume, and logistical concerns. Staying informed about market trends and building relationships with reliable suppliers are essential strategies for securing the best possible pricing. By leveraging expert knowledge and authoritative resources, buyers can make informed decisions that ensure the successful integration of perforated aluminum sheets into their projects, achieving both economic and functional goals.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP