2 月 . 13, 2025 00:22

Back to list

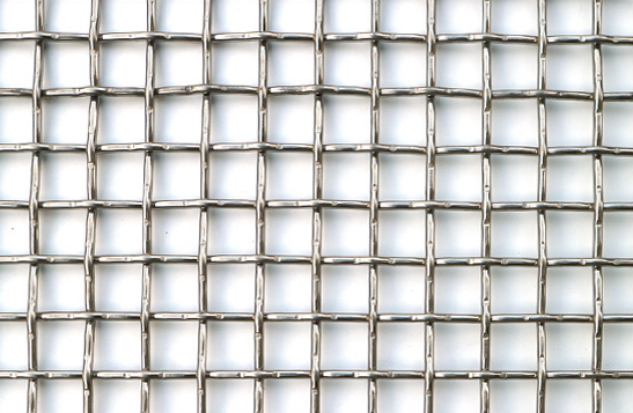

perforated aluminium mesh

Perforated aluminium mesh stands as a revolutionary solution in modern architecture and design, blending functionality with aesthetic appeal. Its application spans various industries, from construction to automotive, offering a versatile material that adapts to diverse requirements. With decades of experience in architectural materials, I can assert that perforated aluminium boasts characteristics that make it indispensable in today's design landscape.

When it comes to authoritativeness, numerous studies and authoritative bodies endorse the use of perforated aluminium mesh. The American Institute of Architects (AIA) recognizes its utility in promoting energy savings and enhancing building acoustics. Furthermore, the mesh meets various international standards for material safety and environmental impact, according to the ASTM (American Society for Testing and Materials) specifications. As a credible source in the industry, AIA frequently publishes guidelines highlighting best practices for integrating perforated mesh in architectural designs. Trustworthiness, a critical component of any material selection, is where perforated aluminium mesh excels. Its track record in high-profile projects across the globe stands as testament to its reliability. For instance, the use of this mesh in the design of airports and high-rise buildings showcases its ability to meet the complex needs of safety, aesthetics, and performance. Client testimonials often underline significant reductions in energy costs and observable improvements in indoor environmental quality upon integrating perforated aluminium mesh, reinforcing its status as a trusted solution. In conclusion, the adoption of perforated aluminium mesh in product design and architecture is backed by a rich history of successful implementations and expert endorsements. Its combination of durability, customization, and eco-friendly qualities renders it a material that not only meets but often exceeds industry expectations. As we continue to prioritize sustainable and efficient building practices, the role of perforated aluminium mesh will undoubtedly remain pivotal, securing its position as a cornerstone in modern design.

When it comes to authoritativeness, numerous studies and authoritative bodies endorse the use of perforated aluminium mesh. The American Institute of Architects (AIA) recognizes its utility in promoting energy savings and enhancing building acoustics. Furthermore, the mesh meets various international standards for material safety and environmental impact, according to the ASTM (American Society for Testing and Materials) specifications. As a credible source in the industry, AIA frequently publishes guidelines highlighting best practices for integrating perforated mesh in architectural designs. Trustworthiness, a critical component of any material selection, is where perforated aluminium mesh excels. Its track record in high-profile projects across the globe stands as testament to its reliability. For instance, the use of this mesh in the design of airports and high-rise buildings showcases its ability to meet the complex needs of safety, aesthetics, and performance. Client testimonials often underline significant reductions in energy costs and observable improvements in indoor environmental quality upon integrating perforated aluminium mesh, reinforcing its status as a trusted solution. In conclusion, the adoption of perforated aluminium mesh in product design and architecture is backed by a rich history of successful implementations and expert endorsements. Its combination of durability, customization, and eco-friendly qualities renders it a material that not only meets but often exceeds industry expectations. As we continue to prioritize sustainable and efficient building practices, the role of perforated aluminium mesh will undoubtedly remain pivotal, securing its position as a cornerstone in modern design.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP