The Versatility and Applications of Perforated Alloy Sheets

Perforated alloy sheets have gained significant attention in various industries due to their unique combination of strength, lightweight nature, and aesthetic appeal. These sheets are made from different types of alloys, such as aluminum, stainless steel, and titanium, each offering specific benefits that cater to diverse applications. In this article, we will explore the features, manufacturing processes, and various applications of perforated alloy sheets.

Understanding Perforated Alloy Sheets

Perforated alloy sheets are metal panels that have been punched with a series of holes, forming a distinctive pattern. These holes can vary in size, shape, and spacing, depending on the specific requirements of the application. The alloy composition of these sheets is crucial, as it determines the sheet's overall strength, corrosion resistance, and suitability for various environments.

One of the primary benefits of using alloys is their enhanced properties. For instance, aluminum alloys are lightweight and highly resistant to corrosion, making them suitable for outdoor applications. In contrast, stainless steel alloys offer superior strength and can withstand high temperatures and harsh environments, thus ideal for industrial applications.

Manufacturing Process

The manufacturing of perforated alloy sheets involves several key steps. First, the chosen alloy material is cut into the desired dimensions. Next, a punching machine or laser cutter is used to create the perforations in the sheet. The design of the holes can be customized to meet specific requirements, such as airflow needs or aesthetic preferences.

After the perforation process, the sheets may undergo additional finishing treatments, such as anodizing or powder coating, to enhance their durability and appearance. Anodizing, particularly for aluminum alloys, provides a protective layer that increases corrosion resistance, while powder coating adds color and texture to the surface.

Applications of Perforated Alloy Sheets

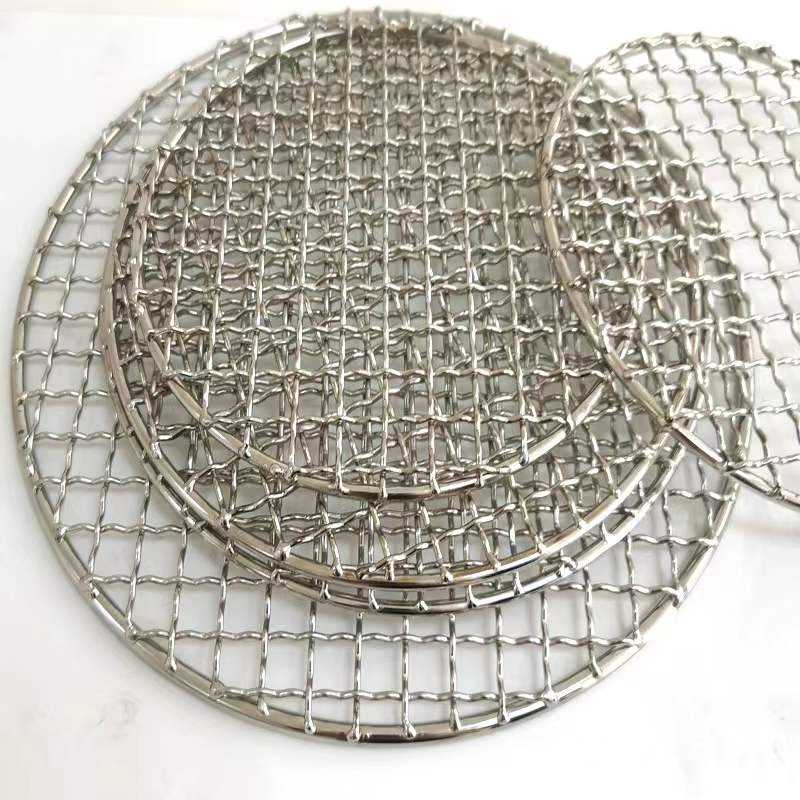

perforated alloy sheet

Perforated alloy sheets are widely used across various industries, each benefiting from their unique characteristics.

1. Architecture and Interior Design In the architectural field, perforated alloy sheets are used for facades, ceiling tiles, and wall coverings. Their aesthetic appeal creates unique visual effects and allows for creative designs that enhance the overall ambiance of spaces. They also offer practical benefits, such as sound attenuation and light diffusion.

2. Industrial Applications The heavy-duty nature of perforated alloy sheets makes them ideal for industrial applications. They are often used in equipment covers, machinery guards, and filters, where strength and durability are paramount. Their perforations can facilitate ventilation while protecting workers and equipment from debris.

3. Automotive Sector In the automotive industry, perforated sheets are used for air intake systems, grills, and sound insulation. Their lightweight properties contribute to fuel efficiency in modern vehicles, while also contributing to the overall design aesthetics.

4. Consumer Products Various consumer products, such as furniture, lighting fixtures, and kitchen equipment, utilize perforated alloy sheets. Their versatility allows designers to create innovative products that marry functionality with style.

5. Environmental Applications Perforated metal sheets are also employed in environmental technology, including filtration systems and sound barriers. Their ability to allow liquids or air to pass through while filtering out larger particles makes them invaluable in waste management and water treatment processes.

Conclusion

In summary, perforated alloy sheets are an essential component in numerous industries, providing a blend of strength, lightweight advantages, and aesthetic appeal. Their versatility makes them suitable for a wide range of applications, from architectural designs to industrial machinery. As technology continues to evolve, the manufacturing processes and applications of perforated alloy sheets are likely to expand, further highlighting their significance in modern design and function. With their unique characteristics, perforated alloy sheets will undoubtedly remain a staple in both creative and practical applications for years to come.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.