Drilled Metal Sheets Applications and Advantages

Drilled metal sheets have become a vital component in numerous industries due to their multifunctional capabilities and adaptability. These sheets are created by perforating a flat sheet of metal with holes of various sizes and patterns, which can enhance both aesthetic appeal and functional properties.

Manufacturing Process

The creation of drilled metal sheets begins with the selection of raw materials, which can include metals like aluminum, steel, copper, and stainless steel. The choice of material often depends on the specific application, desired strength, weight, and corrosion resistance. The manufacturing process involves cutting the metal sheets to predetermined dimensions, followed by drilling or punching holes using specialized machinery. CNC (Computer Numerical Control) machines are commonly employed for precision drilling, allowing for intricate patterns and consistent hole sizes.

Applications Across Industries

1. Construction and Architecture In the construction industry, drilled metal sheets are frequently used as cladding materials for buildings. Their perforated nature allows for light and air to flow through while maintaining structural integrity. Architects often choose these sheets for decorative facades, balcony railings, and sunshades, providing both functionality and visual appeal.

2. Automotive Industry Drilled metal sheets are critical in the automotive sector, where weight reduction is essential for improving fuel efficiency. These sheets are used in various car parts, including chassis components and interior panels, contributing to the overall lightweight design. Their drilled patterns can also facilitate better airflow in engine compartments.

3. Filtration Systems In industries such as water treatment, oil and gas, and food and beverage, drilled metal sheets are integral to filtration systems. The holes in the sheets allow for the passage of liquids while trapping larger particles. This capability can significantly improve the efficiency of these systems, ensuring clean and safe products.

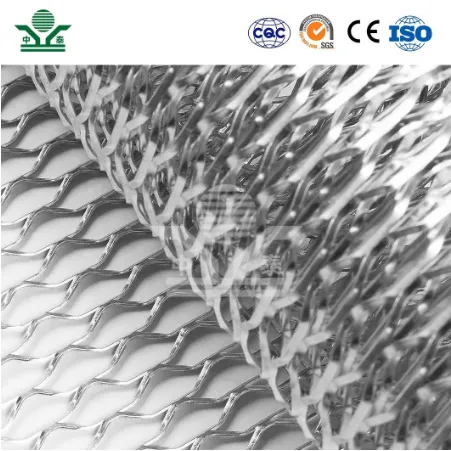

drilled metal sheet

4. Furniture Design The versatility of drilled metal sheets extends to furniture design. Designers incorporate these sheets into tables, chairs, and shelving, offering a modern and industrial aesthetic. The drilled patterns can serve both functional purposes, such as ventilation, and decorative ones, enhancing the overall look of the furniture.

5. Safety and Security Drilled metal sheets are often used in security applications, including fencing and gates. The perforated design allows for visibility while still providing a physical barrier against intrusion. This combination of security and transparency makes them a popular choice for residential and commercial properties.

Advantages of Drilled Metal Sheets

The benefits of drilled metal sheets are numerous. Their lightweight nature combined with strength makes them an ideal choice for various applications. Additionally, the ability to create custom hole patterns caters to specific requirements, making them versatile for any project. The choice of material also allows for different properties, such as corrosion resistance, which is essential in environments exposed to moisture or chemicals.

Furthermore, the aesthetic appeal of drilled metal sheets cannot be overlooked. The intricate designs can enhance the visual interest of any project, from modern architecture to contemporary furniture.

Conclusion

In summary, drilled metal sheets are more than just simple building materials; they embody a fusion of utility and design. Their diverse applications, ranging from construction to automotive and beyond, showcase their importance in modern manufacturing. As industries continue to evolve and innovate, the demand for drilled metal sheets is likely to grow, making them an exciting material for future developments.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.