Understanding Steel Grating Thickness Importance and Applications

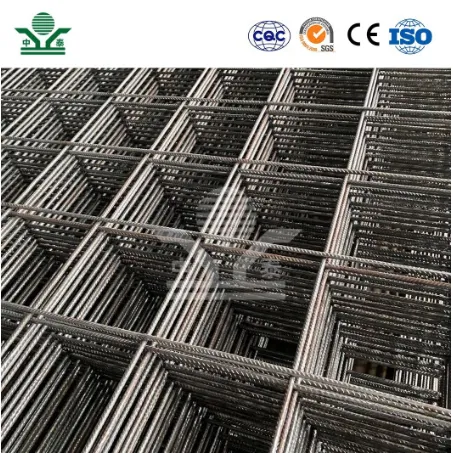

Steel grating is a versatile material widely used in industrial, commercial, and infrastructure applications. Its manufacturing involves a matrix of parallel bars, typically made from carbon or stainless steel, which are welded together to form a grid-like structure. One critical aspect of steel grating that needs careful consideration is its thickness. This article will explore the importance of steel grating thickness, its implications for performance, safety, and applications across various industries.

The Importance of Thickness

The thickness of steel grating plays a crucial role in determining its strength, load-bearing capacity, and overall durability. Thicker gratings can support heavier loads, making them suitable for industrial environments where heavy machinery or foot traffic is common. Conversely, thinner gratings may be ideal for lighter applications, such as walkways or decorative features in commercial settings.

In general, steel grating thickness typically ranges from 1/4 to 1 inch, though variations exist depending on specific requirements. The choice of thickness is often dictated by the intended use of the grating, environmental factors, and safety regulations.

Load-Bearing Capacity

One of the primary reasons for choosing the appropriate thickness in steel grating is to ensure adequate load-bearing capacity. For instance, a platform that supports a significant weight must utilize thicker grating to prevent deformation or failure. Engineers often refer to load charts and specifications provided by manufacturers to make informed decisions on the right grating thickness for their projects.

Additionally, industries such as oil and gas, manufacturing, and warehousing often require custom grating thicknesses to meet specific loads generated by equipment, vehicles, or foot traffic. Thicker gratings are designed to absorb and distribute stress more effectively, enhancing safety and performance.

steel grating thickness

Safety Considerations

Safety is a paramount concern in any industrial or commercial environment. Properly specified steel grating thickness contributes to the overall safety of the structure. For example, grating that is too thin may pose a risk of collapse under excess weight or impact. Furthermore, thin grating surfaces can easily get damaged, creating hazards such as slips and falls.

In many jurisdictions, regulations dictate minimum thickness standards for steel grating to ensure public safety. Therefore, compliance with these standards is not just a best practice but a legal requirement in many cases.

Applications Across Industries

Steel grating is utilized in a variety of applications across multiple sectors. In the construction industry, thick steel grating is often used for stair treads and platforms that experience high traffic or heavy machinery operation. Similarly, in wastewater treatment facilities, thicker gratings provide the durability needed to endure harsh conditions and chemical exposure.

In commercial settings, thinner steel grating may be employed for decorative designs, such as railing systems or aesthetic pathways, where structural load isn’t a significant concern. Retail environments may also leverage lightweight gratings to create appealing displays or support surfaces.

Conclusion

In conclusion, the thickness of steel grating plays a vital role in its performance, safety, and suitability for various applications. Selecting the right thickness is essential for ensuring that the grating meets load requirements, adheres to safety standards, and fulfills the intended purpose effectively. As industries continue to evolve and demand for robust materials increases, understanding the intricacies of steel grating thickness will remain crucial for engineers, architects, and safety professionals alike. By considering these factors, one can ensure that their steel grating solutions are not only functional but also reliable and safe.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.