2 月 . 04, 2025 04:03

Back to list

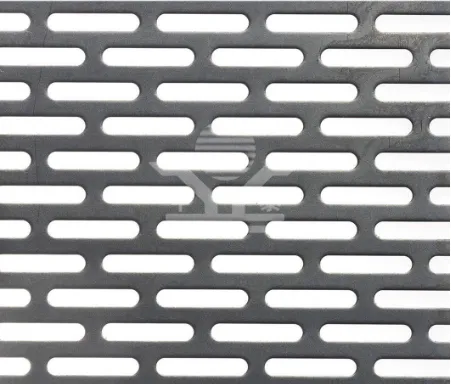

non slip metal grating

Navigating the industrial landscape involves ensuring worker safety, operational efficiency, and maintaining high standards of cleanliness. One critical component that supports these objectives is non-slip metal grating. This specialized industrial product serves multiple sectors, offering not just functionality and safety, but also aligning with industry standards.

Experience in the field confirms that installation and maintenance are key components in the lifecycle of non-slip metal gratings. Proper installation ensures long-term performance and safety. Experts recommend regular inspections and maintenance to sustain the anti-slip properties and structural integrity. Moreover, advancements in technology have refined the manufacture of these gratings, incorporating techniques that enhance durability and grip without compromising on weight and ease of installation. In terms of authoritativeness, non-slip metal grating complies with stringent industry standards and regulations. Safety organizations globally recognize the use of such materials as it effectively addresses potential hazards, thus underlining the product's importance in occupational health and safety protocols. Manufacturers often provide extensive documentation and certification to guarantee compliance with safety and engineering standards, further strengthening the trust in these products. Trustworthiness is further amplified by the testimonies and case studies from industries worldwide that vouch for non-slip metal grating’s role in reducing workplace accidents and enhancing safety. Real-world case scenarios illustrate hundreds of instances where such grating has prevented slips and falls, fostering an environment where safety and efficiency coexist. Company blogs and industry forums are replete with discussions about best practices in selecting and installing these gratings, providing potential users with invaluable insights and firsthand accounts. To encapsulate the essence of non-slip metal grating as a product, consider its role not just as a safety measure, but as an indispensable asset that harmonizes industrial activity with safety norms. The thoughtful design and strategic implementation of these gratings significantly mitigate safety risks while supporting heavy-duty operations. For industries aiming to align with modern safety standards and improve operational effectiveness, non-slip metal grating emerges as an unrivaled solution.

Experience in the field confirms that installation and maintenance are key components in the lifecycle of non-slip metal gratings. Proper installation ensures long-term performance and safety. Experts recommend regular inspections and maintenance to sustain the anti-slip properties and structural integrity. Moreover, advancements in technology have refined the manufacture of these gratings, incorporating techniques that enhance durability and grip without compromising on weight and ease of installation. In terms of authoritativeness, non-slip metal grating complies with stringent industry standards and regulations. Safety organizations globally recognize the use of such materials as it effectively addresses potential hazards, thus underlining the product's importance in occupational health and safety protocols. Manufacturers often provide extensive documentation and certification to guarantee compliance with safety and engineering standards, further strengthening the trust in these products. Trustworthiness is further amplified by the testimonies and case studies from industries worldwide that vouch for non-slip metal grating’s role in reducing workplace accidents and enhancing safety. Real-world case scenarios illustrate hundreds of instances where such grating has prevented slips and falls, fostering an environment where safety and efficiency coexist. Company blogs and industry forums are replete with discussions about best practices in selecting and installing these gratings, providing potential users with invaluable insights and firsthand accounts. To encapsulate the essence of non-slip metal grating as a product, consider its role not just as a safety measure, but as an indispensable asset that harmonizes industrial activity with safety norms. The thoughtful design and strategic implementation of these gratings significantly mitigate safety risks while supporting heavy-duty operations. For industries aiming to align with modern safety standards and improve operational effectiveness, non-slip metal grating emerges as an unrivaled solution.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP