2 月 . 07, 2025 01:01

Back to list

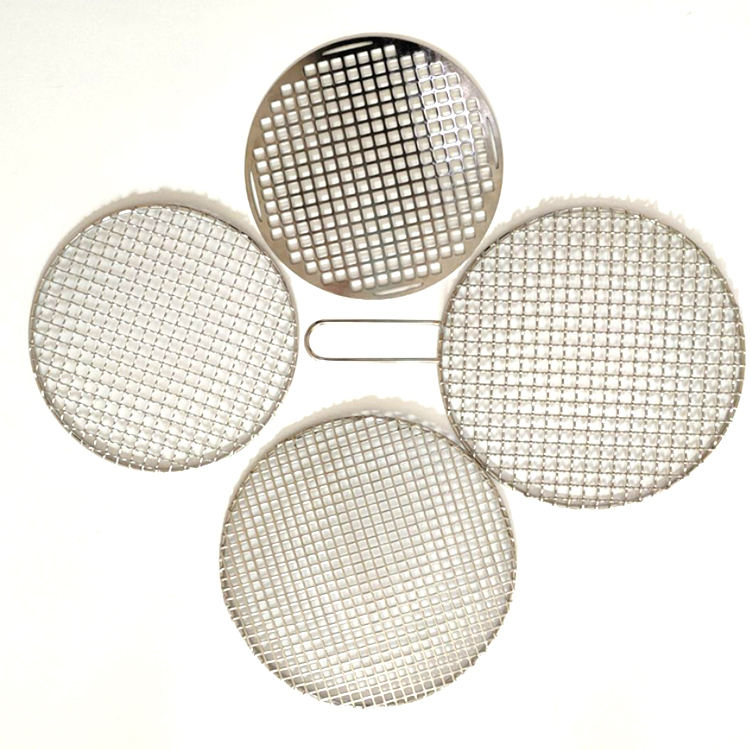

metal sheet perforated round hole

Navigating the multifaceted world of metal sheet perforation presents opportunities for optimizing both aesthetics and functionality in industrial and architectural applications. Among the myriad of options available, perforated metal sheets with round holes stand out as a versatile solution, combining exceptional utility with a sleek design. This article will delve into the experiential benefits, technical expertise, authoritative advancements, and trustworthiness that make round-hole perforated metal sheets an exemplary choice for various projects.

When considering authoritativeness, it's essential to highlight the advancements and standards that govern the production and application of perforated metal sheets. Industry standards define the parameters for hole size, distribution, and sheet thickness, ensuring consistency and safety in usage. Leading manufacturers have established their dominance by adhering to, and often exceeding, these standards, providing clients with reliable products that stand the test of time. The accumulation of decades of research and development in perforated sheet technology underscores the authoritative stance these manufacturers hold, ensuring that clients receive only the best in design and performance. Trustworthiness emerges from the satisfaction of users who have experienced the efficiency and aesthetic value of round-hole perforated sheets firsthand. Customer testimonials often underscore the transformative impact these sheets have on the building environment. Their application ranges from noise reduction in urban areas to serving as filters and diffusers in industrial settings, providing an assurance of quality and effectiveness. The ability to withstand harsh conditions without deterioration further bolsters consumer confidence, affirming the product's reputation as a trustworthy solution in a demanding market. In conclusion, the incorporation of metal sheets with perforated round holes into both industrial and architectural projects offers numerous benefits grounded in experience, technical expertise, authority, and trust. These sheets provide a dual advantage, delivering both functional and aesthetic enhancements while maintaining exceptional durability and adaptability. As a product class with a promising future, round-hole perforated metal sheets continue to evolve, embracing innovative practices and technologies to meet the ever-changing needs of designers, architects, and engineers.

When considering authoritativeness, it's essential to highlight the advancements and standards that govern the production and application of perforated metal sheets. Industry standards define the parameters for hole size, distribution, and sheet thickness, ensuring consistency and safety in usage. Leading manufacturers have established their dominance by adhering to, and often exceeding, these standards, providing clients with reliable products that stand the test of time. The accumulation of decades of research and development in perforated sheet technology underscores the authoritative stance these manufacturers hold, ensuring that clients receive only the best in design and performance. Trustworthiness emerges from the satisfaction of users who have experienced the efficiency and aesthetic value of round-hole perforated sheets firsthand. Customer testimonials often underscore the transformative impact these sheets have on the building environment. Their application ranges from noise reduction in urban areas to serving as filters and diffusers in industrial settings, providing an assurance of quality and effectiveness. The ability to withstand harsh conditions without deterioration further bolsters consumer confidence, affirming the product's reputation as a trustworthy solution in a demanding market. In conclusion, the incorporation of metal sheets with perforated round holes into both industrial and architectural projects offers numerous benefits grounded in experience, technical expertise, authority, and trust. These sheets provide a dual advantage, delivering both functional and aesthetic enhancements while maintaining exceptional durability and adaptability. As a product class with a promising future, round-hole perforated metal sheets continue to evolve, embracing innovative practices and technologies to meet the ever-changing needs of designers, architects, and engineers.

Next:

Latest news

-

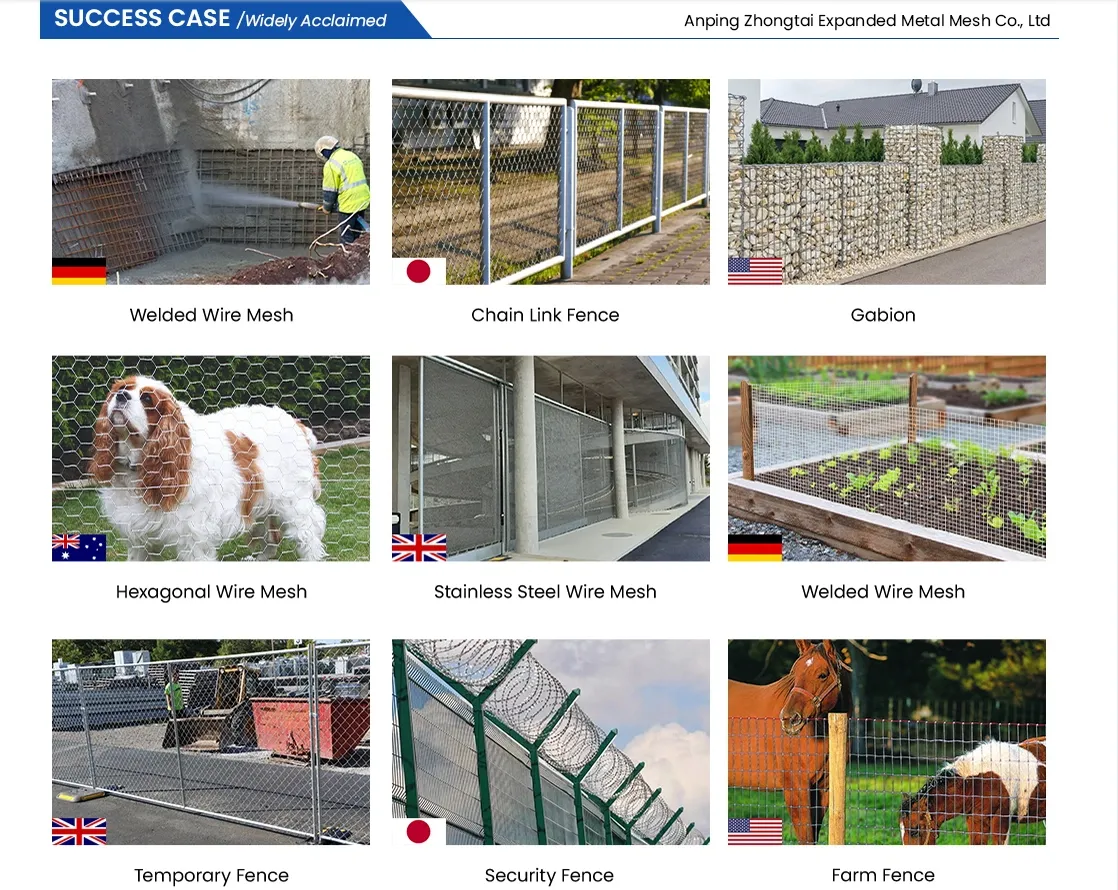

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP